Regulatory Oversight Report on the Use of Nuclear Substances in Canada: 2020

Executive summary

This document presents the regulatory oversight report (ROR) produced by the CNSC’s Directorate of Nuclear Substance Regulation (DNSR) for the activities falling under its regulatory responsibilities: the use of nuclear substances and prescribed equipment in the medical, industrial, academic and research, and commercial sectors. This report also covers select waste nuclear substance licensees, regulated by the CNSC’s Directorate of Nuclear Cycle and Facilities Regulation, which are not reported on in other RORs.

To assess the safety performance of the licensees covered by this ROR, CNSC staff conducted regulatory oversight activities throughout 2020, including inspections, reviews of reports submitted by licensees, reviews of events and incidents, and general communication and exchanges of information with licensees. The results of these oversight activities show that the use of nuclear substances and prescribed equipment in Canada remains safe and secure.

In addition to performance results, the report provides the Commission with information about stakeholder engagement, which is a critical element of the CNSC’s regulatory approach. Given the breadth of licensees regulated in the area of nuclear substances, a particular focus is on reaching and engaging with licensee communities.

In 2020, the global COVID-19 pandemic impacted CNSC staff and licensees, as it did every other aspect of Canadian society. The CNSC activated its Business Continuity Plan on March 15, 2020, and all non-critical oversight activities, including routine onsite inspections, were suspended. While access to CNSC systems was initially limited, which temporarily affected licensing- and certification-related activities, the CNSC ensured that staff received the necessary equipment to work remotely within a short time frame. As a result, and owing to the fact that the licensing and certification processes for nuclear substances and prescribed equipment were already largely digital, CNSC staff were able to conduct these activities with effectively no interruption of service during the pandemic. The biggest impact of the pandemic was on compliance activities, with the constraints on onsite inspections due to local health guidelines requiring CNSC staff to pivot to remote inspections for most of 2020.

Due to the pause in inspections in the early stages of the pandemic, as well as the fact that remote inspections take longer than onsite inspections, CNSC staff conducted fewer inspections in 2020 – less than half the number of a typical year. This reduction in inspections unavoidably introduces an incremental increase in risk, taking into account that the prime responsibility for safety remains with the licensees. However, it is important to consider this risk in context: While it is possible that fewer inspections could lead to a slight increase in the probability of unsafe work practices among the licensees covered by this ROR, the consequences of any resulting incidents remain relatively low (on average) due to the nature of the nuclear substances and prescribed equipment used by these licensees.

Nonetheless, CNSC staff have continued to treat any risk seriously; in line with this practice, staff undertook steps in 2020 to mitigate any risks introduced by the reduction in inspections:

- The revisions to the 2020 inspection plan were made on a risk-informed basis, with the revised plan maintaining a focus on the highest-risk category of licensees; in the end, CNSC staff were successful in exceeding the revised plan for these high-risk inspections.

- CNSC staff continued to monitor other performance indicators, including reviewing annual compliance reports and reported events.

- CNSC staff maintained their capacity to respond quickly (in person, if necessary) to any reported event that could pose an immediate risk to health and safety.

- CNSC staff engaged in a campaign to reach out to the licensees, to assess their status and remind them of their responsibility for safety.

As a result of these measures, it is CNSC staff’s conclusion that the incremental increase in risk due to the reduction in inspections in 2020 remained acceptable. This conclusion is substantiated by the 2020 performance results presented in this ROR, which remained consistent with previous years and continued to demonstrate high levels of compliance across the sectors covered. That being said, it is important to note that the smaller sample size of inspections in 2020 makes it challenging to compare performance results year over year. The true impact on performance because of the pandemic will only be evident after trending data over a number of years – this is something that CNSC staff will continue to monitor closely.

While the increased risk after a year of fewer inspections remains manageable, a continued reduction in inspections moving forward could raise this risk. As such, CNSC staff will continue to apply a risk-informed approach to compliance oversight and inspection planning, as the risk from COVID-19 changes.

Based on the CNSC’s strong regulatory oversight, flexibility, and immediate action responding to the pandemic, the evaluations presented in this report demonstrate the following:

- Compliance performance across all sectors was generally high, with licensees undertaking appropriate corrective actions for any instances of non-compliance.

- All enforcement actions issued in 2020 were closed in a timely way.

- Doses to workers remained generally low, with 3 out of the 58,967 workers monitored reporting doses above the annual regulatory limit. While none of these resulted in negative health effects, the CNSC takes any exceedances of a regulatory dose limit seriously and requires the licensee to perform an acceptable investigation so the situation is not repeated.

- All reported events were of low or negligible safety significance.

- Despite the challenges posed by COVID-19, the CNSC’s risk-informed approach ensured the safety of nuclear substances and prescribed equipment in Canada.

Use of nuclear substances in Canada: 2020

The Regulatory Oversight Report on the Use of Nuclear Substances in Canada: 2020 summarizes the safety performance of 1,496 licensees, which hold a total of 2,079 licences. The CNSC authorizes licensees to use nuclear substances and prescribed equipment in the medical, industrial, academic and research, and commercial sectors. For a full description of the licensees covered within this report, refer to the technical briefing to the Commission on nuclear substances in Canada (CMD 18-M49) Additional data on licensees is available in appendix A.

This ROR includes certain waste nuclear substances licensees that are not covered in any other CNSC ROR. By request of the Commission, appendix A.6 specifically provides additional information on Mississauga Metals and Alloys, related to the record of decision for their exemption request.

CNSC staff use many metrics to evaluate licensees’ safety performance. This report uses a subset of these metrics, which – when taken together – will provide a well-rounded picture of performance for the licensees covered by this report. The metrics used in this report are:

- compliance performance

- enforcement actions

- doses to workers

- reported events

To measure compliance performance, CNSC staff use a well-established Safety and Control Area Framework. The framework includes 14 safety and control areas (SCAs) covering all technical areas of regulatory oversight. While CNSC staff review and assess performance in each SCA (if applicable), the ROR covers only those that are most useful and applicable in providing a good overall indication of the safety performance of the licensees. These are: management system, operating performance, radiation protection, and security. The waste nuclear substance licensees included in this report are covered within the commercial sector. They are the only licensees presenting performance data for the environmental protection and the conventional health and safety SCAs. This is because, unlike the nuclear substance licensees, waste nuclear substance licensees have the potential for environmental releases as well as a potentially higher risk in the area of conventional health and safety.

In the past, stakeholders have requested that the packaging and transport SCA be included in this ROR. CNSC staff acknowledge that this is an important SCA, given the high volume of transport activities associated with nuclear substance licensees. However, since the packaging and transport SCA does not apply universally to all nuclear substance licensees, it would be challenging to present performance data in a meaningful way in the ROR. Instead, a review of the reported events related to packaging and transport provides a more meaningful indicator for this SCA – see section 4.0, Reported events , for an analysis of this indicator.

In addition to the standard review of performance indicators, the 2020 ROR includes a specific analysis of the impacts of the COVID-19 pandemic on DNSR’s regulatory oversight. After resolving system access challenges in the early weeks of the stay-at-home order, CNSC staff were able to maintain licensing and certification services under remote working conditions throughout 2020. Even prior to the pandemic, these activities were largely digital, resulting in minimal impacts from the COVID-19 pandemic. On the other hand, compliance efforts were affected by pandemic-related limitations to air and local travel, and due to the fact that some licensees limited their operations because of the pandemic. For example, some licensees in the medical sector were operating at reduced capacity and for 2 to 3 days per week, whereas other medical licensees were operating normally but with restricted activities to accommodate clinically urgent patients. In the industrial sector, some construction sites were closed and limiting site access, some staff were working from home, and some were working with restrictions to their activities.

As such, DNSR had to revise its original inspection plan to account for these constraints. The original (pre-pandemic) plan called for approximately 750 inspections; CNSC staff continued to monitor changing conditions throughout the year and adjusted the plan accordingly, ultimately planning approximately 300 inspections for 2020. The revisions were conducted on a risk-informed basis, with priority given to the highest-risk inspections. In the end, staff successfully exceeded the plan, conducting a total of 371 inspections in 2020. Of these, 178 were remote inspections and 193 were onsite. A detailed description of compliance effort during the pandemic is included below in section 1.6.

This ROR includes data in both the body and appendices; the main body of the report provides a high-level overview of the CNSC’s regulatory efforts, along with the licensees’ performance; the detailed data to support this overview is found in the appendices.

1.0 Compliance performance

Appendix B covers the full 2020 performance data, broken down by SCA, by sector and by subsector. In addition, the data shows the 5-year performance trends within each of these categories.

During licensing and compliance activities, CNSC staff evaluate the licensee’s performance within each relevant SCA by reviewing licensee documents and conducting inspections. Owing to the broad nature of the different activities conducted by the licensees covered, not all SCAs apply to all activities or all licensees. All relevant SCAs are assessed during compliance inspections and reviews of licensees’ documents, and a compliance rating is assigned for each SCA. Each SCA covers multiple items. Some of these are administrative in nature and are considered relatively low risk, while others are linked to an immediate risk to health, safety or security, and therefore any findings against these items during an inspection must be addressed immediately.

CNSC staff track and follow up on all required corrective actions arising from below-satisfactory performance, to ensure that all items of non-compliance are addressed to the satisfaction of the CNSC. For any instances of non-compliance that pose immediate risk to health, safety or security, enforcement actions may be taken, such as the issuance of orders. Administrative monetary penalties (AMPs) may also be used as part of a graduated approach to compliance, for issues that do not pose an immediate risk to health or safety. A description of the ratings is provided in appendix G.

Staff perform inspections to review and report on the licensees’ performance under the subset of SCAs evaluated. The following 4 SCAs are the most relevant indicators of safety performance for licensees in the sectors covered in this ROR: management system, operating performance, radiation protection and security. These SCAs apply to most of the licensees and together provide an indication of licensees’ overall safety performance. The exception is the waste nuclear substance licensees, for which this ROR presents performance results under 2 additional SCAs: environmental protection and conventional health and safety. A brief overview of each of these SCAs is provided below, with more details provided in appendix B.

Overall, as with past years, licensees showed satisfactory compliance ratings in the SCAs evaluated. A list of inspections performed in 2020 is available in appendix F. Where items of non-compliance were identified, CNSC staff ensured that licensees took appropriate corrective actions. Licensees immediately addressed any items of non-compliance that had immediate risks to health, safety or security.

Appendix B.5 presents the inspection results by subsector, which provide another perspective on licensee performance in 2020. These results demonstrate that the performance of the nuclear medicine subsector continues to be lower than that of other subsectors, particularly in the operating performance and radiation protection SCAs. CNSC staff continue to work on promoting compliance within this subsector, although progress on this front was difficult in 2020, given the challenges in inspecting nuclear medicine licensees this past year. For example, accessing hospitals was difficult during the pandemic, and CNSC staff furthermore recognized that these licensees needed to prioritize their resources on the response to COVID-19. As a result, the small number of inspections conducted for this subsector focused on those licensees for which CNSC staff felt that additional regulatory oversight was required, whether due to poor past performance or because the inspections for those licensees were overdue. CNSC staff will continue to monitor this subsector in the future, to see if further regulatory response is required.

Even though numbers of inspections decreased due to limitations to travel and access to licensee sites, analysis of all licensee data demonstrated that performance ratings were similar to those of previous years across all SCAs at the sector level. DNSR continued to use a risk-informed approach to inspections, and other compliance activities continued, such as reviews of annual compliance reports (ACRs), events, and dose data. Despite the lower number of inspections performed in 2020, CNSC staff are confident that the performance trends identified are a true indication of licensee performance. On the other hand, the smaller sample size in 2020 makes it challenging to compare results year over year. This means it is not possible to draw meaningful conclusions from any apparent upward or downward trending in performance this year. As regulatory activities return to normal in the future, subsequent RORs will more accurately identify any deviations in trends. DNSR will closely monitor performance in the coming years, to understand future impacts and adjust the regulatory oversight approach as required.

1.1 Management system

In 2020, licensees continued to maintain strong performance in the management system SCA. Overall, 96% of the licensees inspected received ratings of satisfactory for this SCA, and there were no unacceptable ratings. The management system SCA has been performing with similar results over the past few years.

Refer to appendix B.1 for additional information.

1.2 Operating performance

Licensees’ performance in the operating performance SCA slightly decreased from previous years. Of the licensees inspected, 83% received ratings of satisfactory for this SCA. There were no unacceptable ratings in this SCA.

Refer to appendix B.2 for additional information.

1.3 Radiation protection

Licensees’ overall performance in the radiation protection SCA improved, with 84% of licensees receiving ratings of satisfactory in 2020, compared to 80% in 2019. Even though the total number of inspections was lower, the percentage of compliance for 2020 is similar to the previous 5 years performance for radiation protection. These ratings need to be considered in the context of lower numbers of inspections, and the reader should not place too much emphasis on these numbers as indicative of overall performance trending.

It is important to note that the revised Radiation Protection Regulations came into effect late in the reporting period for this ROR. Therefore, while a downturn in performance is possible immediately following the implementation of new regulatory requirements, no impact is yet evident but there may be impacts for the 2021 ROR. Refer to appendix B.3 for additional information.

One licensee, in the industrial sector, received an unacceptable rating for radiation protection. As a result, CNSC staff issued an order. The licensee has complied with the terms of the order and put corrective measures in place to address all items of non-compliance found during the routine Type II inspection that led to the issuance of the order. The order is now closed; see appendix C, table 17, for more details.

1.4 Security

In 2020, licensees’ performance in the security SCA remained consistent with the previous 5 years, with 93% of the licensees inspected demonstrating they had adequate provisions in place to prevent the loss, sabotage, illegal use or illegal removal of nuclear substances and prescribed equipment in their care and control.

DNSR licensees continued to maintain strong compliance with applicable security regulatory requirements, including the general requirements contained in the General Nuclear Safety and Control Regulations, as well as in REGDOC-2.12.3, Security of Nuclear Substances: Sealed Sources and Category I, II and III Nuclear Material, applicable to sealed sources and radiation devices. REGDOC‑2.12.3 came into force as a requirement for Category 1 and 2 sealed sources/radiation devices in May 2015, and for Category 3, 4 and 5 sealed sources/radiation devices in May 2018. In spite of an initial, and expected, reduction in compliance ratings following these new regulatory requirements coming into force, data in the ROR’s tables and graphs shows that licensees have regained their compliance with requirements under the security SCA.

Refer to appendix B.4 for additional information.

1.5 Environmental protection and conventional health and safety

Performance in the environmental protection SCA and conventional health and safety SCA for 2020 are reported on only for the waste nuclear substance subsector. No waste nuclear substance licensees received below-expectations or unacceptable ratings in the environmental protection SCA. The waste nuclear substance licensees continued to manage and monitor environmental releases as a result of licensed activities. These releases were kept well below regulatory limits. There were 2 unplanned releases to the environment as a result of licensed activities in 2020. However, the radioactivity concentration of the first release was below unconditional clearance levels, and the radioactivity concentration of the second release was well below the licensees’ action levels. Therefore, the releases had no impact on the health, safety and security of persons or the environment.

No waste nuclear substance licensees received below-expectations or unacceptable ratings in the conventional health and safety SCA. The licensees continued to implement health and safety programs in accordance with the applicable occupational health and safety legislation to protect the health and safety of their workers.

1.6 Compliance efforts during the pandemic

At the beginning of the pandemic, to ensure CNSC staff and licensee safety, the CNSC suspended all onsite inspections. During this pause in inspections, staff worked to establish contact with licensees to review their status of operations. For the most part, licensees were continuing to operate, in some manner, despite the pandemic. Once staff were comfortable with their knowledge about licensee operations, work pivoted to developing an approach for safely and effectively conducting compliance oversight under pandemic conditions. The initial inspection plan was revised to account for the time lost during the early lockdown, leading to an approximately 25% reduction in planned inspections. At the same time, CNSC staff devised processes and procedures for conducting remote inspections, along with a modified compliance verification strategy to help guide the decision as to which type of inspection to conduct, depending on the changing circumstances of the pandemic. (See section 1.7 for more information on the experience with remote inspections.) Successive waves of the pandemic throughout the year, combined with the realization that remote inspections were taking longer than originally expected, led to ongoing adjustments to the inspection plan. The original plan of approximately 750 inspections was ultimately reduced to approximately 300 planned inspections. In the end, CNSC staff successfully exceeded this plan, conducting a total of 371 inspections in 2020 – 178 of these were remote inspections and 193 were onsite.

As always, CNSC staff applied a risk-informed approach to developing the initial inspection plan and then to updating the plan for each successive adjustment, maintaining at all times a focus on the highest-priority inspections. All high-priority inspections in the revised 2020 plan were completed.

The 371 inspections conducted in 2020 represent approximately half the number carried out in a typical year. This reduction in inspections decreases the CNSC’s ability to confirm the safe performance of its licensees. In addition, the reduced presence of inspectors onsite could lead to a decrease in licensee compliance with regulatory requirements. This does not mean that fewer inspections automatically lead to an abrupt or significant spike in risk, but rather that the reduction could introduce a gradual increase in the probability that some licensees would engage in unsafe work practices. To put this in perspective, the CNSC has an established risk profile for the sectors covered by this ROR, which concludes that the consequences of an accident in these sectors (on average) would be relatively low. This is because many licensees in these sectors deal with sealed sources contained in radiation devices or relatively small amounts of nuclear substances, with relatively low levels of radiation. By contrast, the risk profile has assessed the probability of an accident to be relatively high, due in part to the large number of licensees covered. A reduction in inspections could lead to an incremental increase in the probability of unsafe work practices leading to an accident, but would not increase the consequences of such an accident – as a result, the total risk level would only increase by a small amount.

In addition to this analysis of the risk profile, it is important to remember that inspections are not the only element of the CNSC’s compliance oversight. Throughout 2020, CNSC staff continued to review annual compliance reports submitted by licensees and continued to monitor reported events. Both of these activities provide valuable indicators of safe performance. With all of this taken into account, CNSC staff have concluded that the risk posed by the reduced number of inspections conducted in 2020 remains acceptable.

That being said, CNSC staff recognize that conducting a reduced number of annual inspections is not sustainable going forward. There is a potential for licensee performance to decrease if not inspected regularly. In addition, reduced compliance performance information that would typically be gathered during onsite inspections would eventually impact CNSC staff’s ability to make risk-informed licensing decisions. As such, staff are currently focused on recalibrating the CNSC’s regulatory oversight of nuclear substances licensees by steadily increasing the number of onsite inspections as vaccination rates rise and the risks from COVID-19 continue to decline. At the same time, CNSC staff will continue to make use of the advantages offered by remote inspections, which are further described in the next section.

1.7 Remote inspections

As noted, CNSC staff developed a modified compliance verification strategy in order to guide the decisions on which type of compliance activity (onsite or remote) to perform during the pandemic. These decisions were made on a case-by-case basis, based on the status of the pandemic at that time, with the priority placed on the health and safety of both CNSC and licensee staff.

Fortunately, many inspections could be conducted remotely and staff verified most of the same criteria that would normally be checked as part of an onsite inspection. Remote verification was limited to the examination of records and photos provided by the licensee as well as to the conduct of basic interviews with the radiation safety officer (RSO). Where possible, staff used videoconferencing software to observe work being performed. Staff deferred some inspections where it was not possible to perform them remotely. These fell into 2 main categories:

- inspections where verification of specific security-related regulatory requirements was not possible over remote means due to the sensitivity of information that needed to be exchanged

- inspections where independent verification by an inspector was required or where remote inspection technology was not available

Staff identified 2 main challenges to remote inspections: having a reliable and secure platform for meeting with the licensee and having an efficient way for licensees to securely send large amounts of documentation. In addition, remote inspections have proven to take longer than expected and have typically taken longer to conduct than onsite inspections.

In the spirit of continuous improvement, staff collected and analyzed licensee feedback related to the remote-inspection process. While licensees all reported that the process was effective and believed it was a positive experience, data gathering and the submission of the requested records were challenging.

Despite the shift to remote inspections, staff continued to respond onsite for events, to issue enforcement actions or to perform specific onsite compliance activities if warranted. Staff performed any onsite oversight activities on a risk-informed basis in observance of relevant COVID-19 health protocols.

While they can be effective under certain circumstances, remote inspections do not provide a complete assessment of all performance-based activities. In comparison, onsite inspections allow staff to make better use of visual clues during interviews and they eliminate some of the limitations related to protected document access as well as physical observations of workers performing their tasks. Furthermore, the initial assumption was that remote inspections would take less time overall to complete. However, the opposite was observed due to the additional planning required and logistical steps involved in planning remote inspections. Overall, while they are not sufficient on their own, remote inspections provide staff with a functional tool to monitor compliance and they will remain part of the compliance program moving forward, in combination with onsite inspections. Staff are now well placed to address any future disruptions in their ability to conduct onsite inspections during exceptional circumstances.

2.0 Enforcement

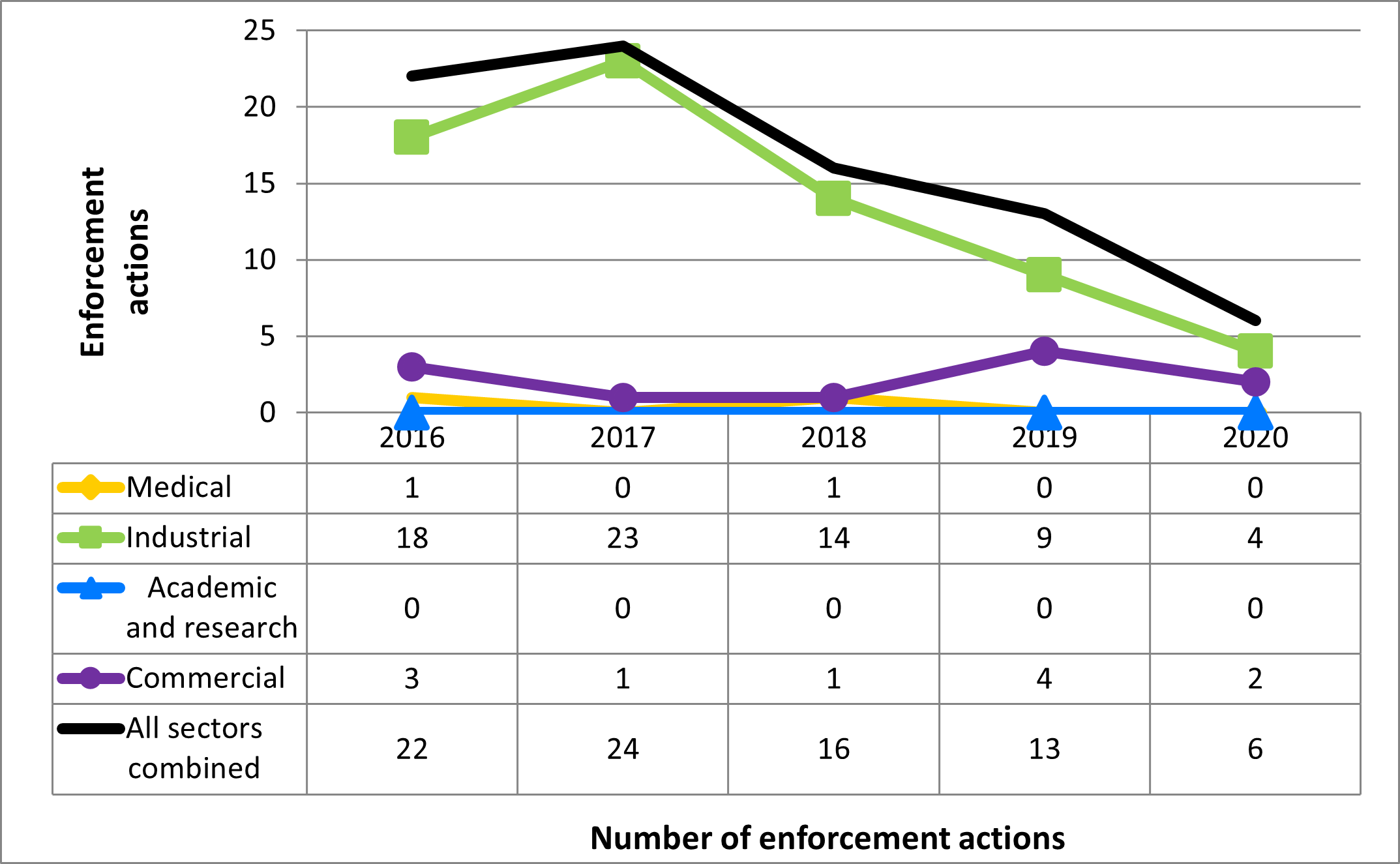

Appendix C presents enforcement action data by sector over the past 5 years.

The CNSC uses a graduated approach to enforcement to encourage compliance. When non-compliance (or continued non-compliance) has been identified, CNSC staff assess the significance of the non-compliance and determine the appropriate enforcement action.

In 2020, the CNSC issued 4 orders and 2 AMPs to licensees. Half of these enforcement actions were issued as a result of remote inspections, which further demonstrates the effectiveness of the CNSC’s regulatory oversight during a pandemic.

As DNSR completed roughly half the typical number of inspections per year, it was also observed that enforcement actions issued were also roughly half the typical number issued, compared to the number in 2019. Although affected by many variables, enforcement actions tend to be issued as a result of inspections; as such, fewer inspections typically result in fewer enforcement actions. Most of the enforcement actions were taken against licensees in the industrial sector, consistent with trends from previous years. All enforcement actions are closed, and the CNSC is satisfied that the licensees have addressed the conditions of the orders/AMPs.

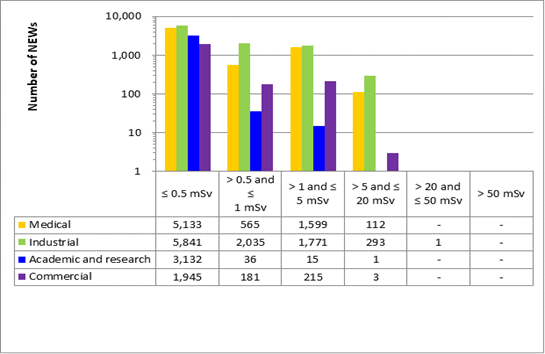

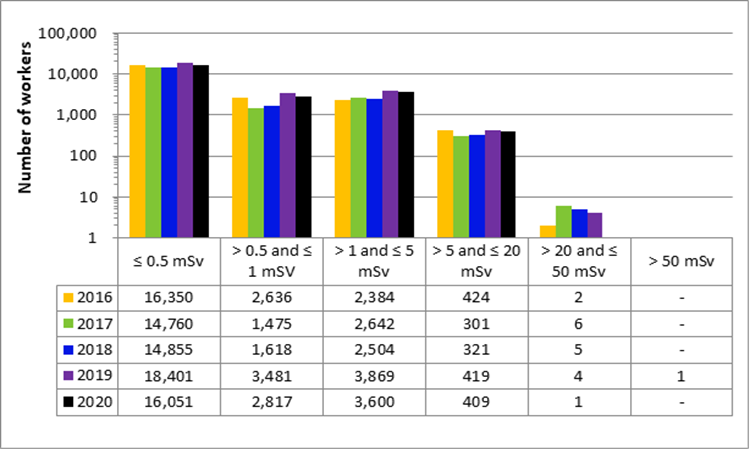

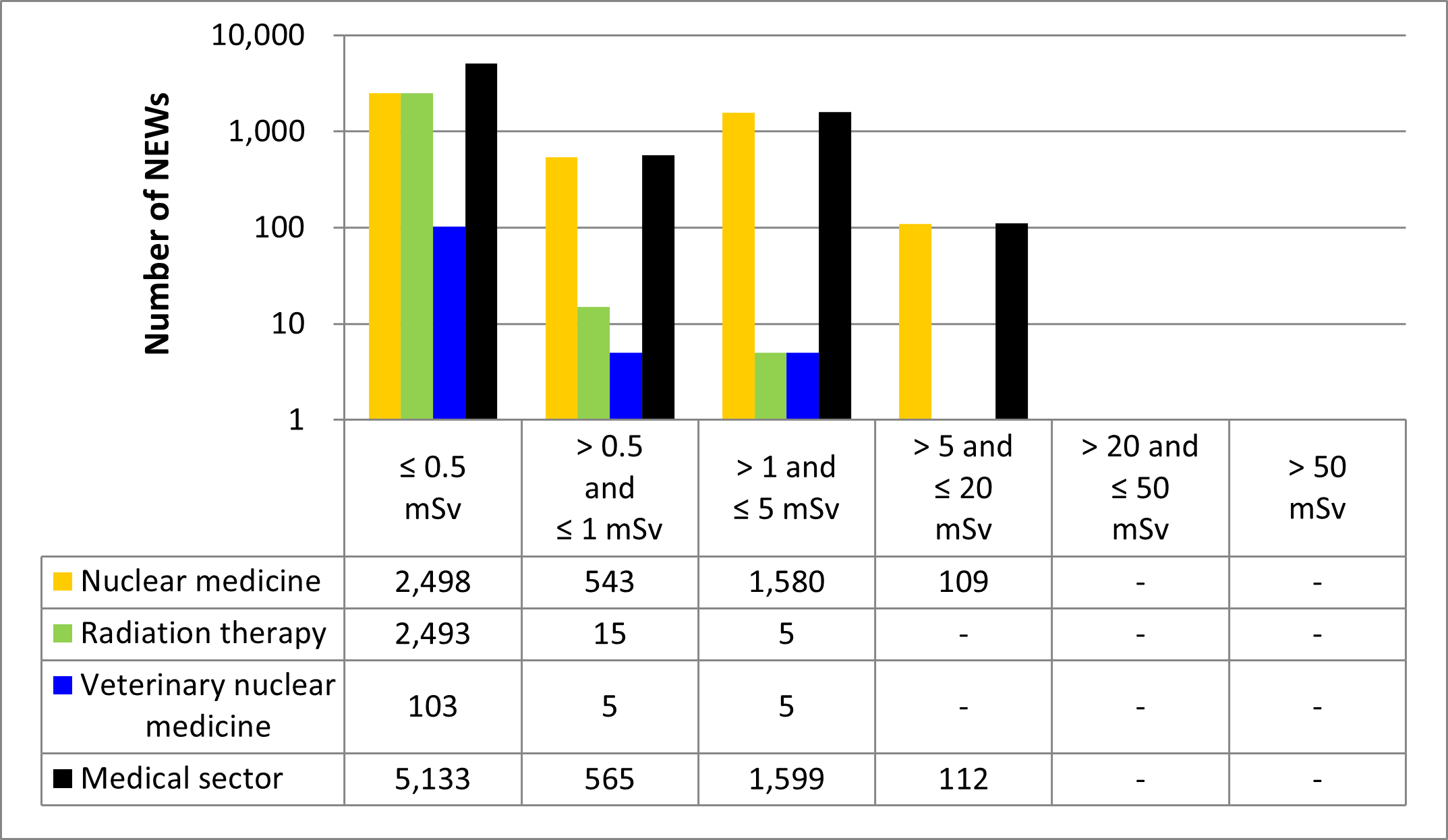

3.0 Effective doses to workers

Appendix D presents the full datasets and additional information on effective doses to workers in 2020.

Licensees are required to keep radiation doses to persons below regulatory limits and as low as reasonably achievable (ALARA) in accordance with their radiation protection program referenced in their licence.

In 2020, doses were monitored for 58,967 workers in the 4 sectors. Of those workers, 22,861 were nuclear energy workers (NEWs). The remaining 36,106 were not designated as NEWs and are referred to as non-NEWs in this report. Exposures to radiation continued to be very low for workers covered in this ROR for 2020, consistent with previous reporting years.

In 2020, no NEWs received doses above the regulatory limit of 50 mSv per calendar year, while 3 non‑NEWs reported dosimetry readings above the applicable dose limit of 1 mSv per calendar year. The 3 instances are described in the following paragraphs.

A non-NEW received a cumulative effective dose of 1.3 mSv, across 2 dosimetry periods. The worker first received a dose of 0.93 mSv during the January to March 2020 period. While not above the annual regulatory dose limit, the dose exceeded the licensee’s action level. Under typical circumstances, the licensee would have removed the worker from any work likely to result in a further dose, in order to avoid exceeding the annual limit. However, due to the COVID-19 pandemic, there was a delay in submission of dosimeters to the licensed dosimetry service provider, which caused a delay in the licensee becoming aware of the action level exceedance. As a result, the worker was allowed to continue working and received a further dose of 0.37 mSv during the July to September 2020 period. (The worker did not receive a dose during the April to June 2020 period, as no work was performed then due to the pandemic.) The licensee determined that the worker did not follow the established safe work practices, which led to a higher than normal personal dose. An event initial report (EIR) was presented to the Commission in January 2021 in CMD 21-M10.

A non-NEW received an effective dose of 3.54 mSv, as reported for the October to December 2019 dosimetry period. Although this falls outside the period covered by this ROR, the radiation safety officer received the dosimetry report from the National Dosimetry Service in March 2020, which is why this dose is included in the 2020 data. The licensee determined that part of the dose was non-occupational and was received while the worker was caring for a relative who had undergone a nuclear medicine test in November 2019. The licensee’s investigation was unable to identify with certainty any specific incident or event that could have resulted in a total dose reading of 3.54 mSv. A dose change request for the portion of the dose that was demonstrated to be non-occupational was approved. An EIR was presented to the Commission in September 2020 in CMD 20-M27.

A dosimeter assigned to a non-NEW worker recorded a dose of 1.28 mSv for the April to June 2020 period. The worker was only assigned to an area with a potential for dose exposure for 6 days out of the 3-month dosimetry period and, as is typical practice for this licensee, the employees work in teams of at least 2 people. All dosimetry reports for the other workers showed no dose received. The worker who received the dose did not lose control of the dosimeter or leave the premises with it. Considering that no excess dose was received by the other worker, and that there were no reported failures in access control procedures nor equipment failures during that period, it is highly unlikely that this dose was received from activities regulated by the CNSC. Nonetheless, it remains in the 2020 data.

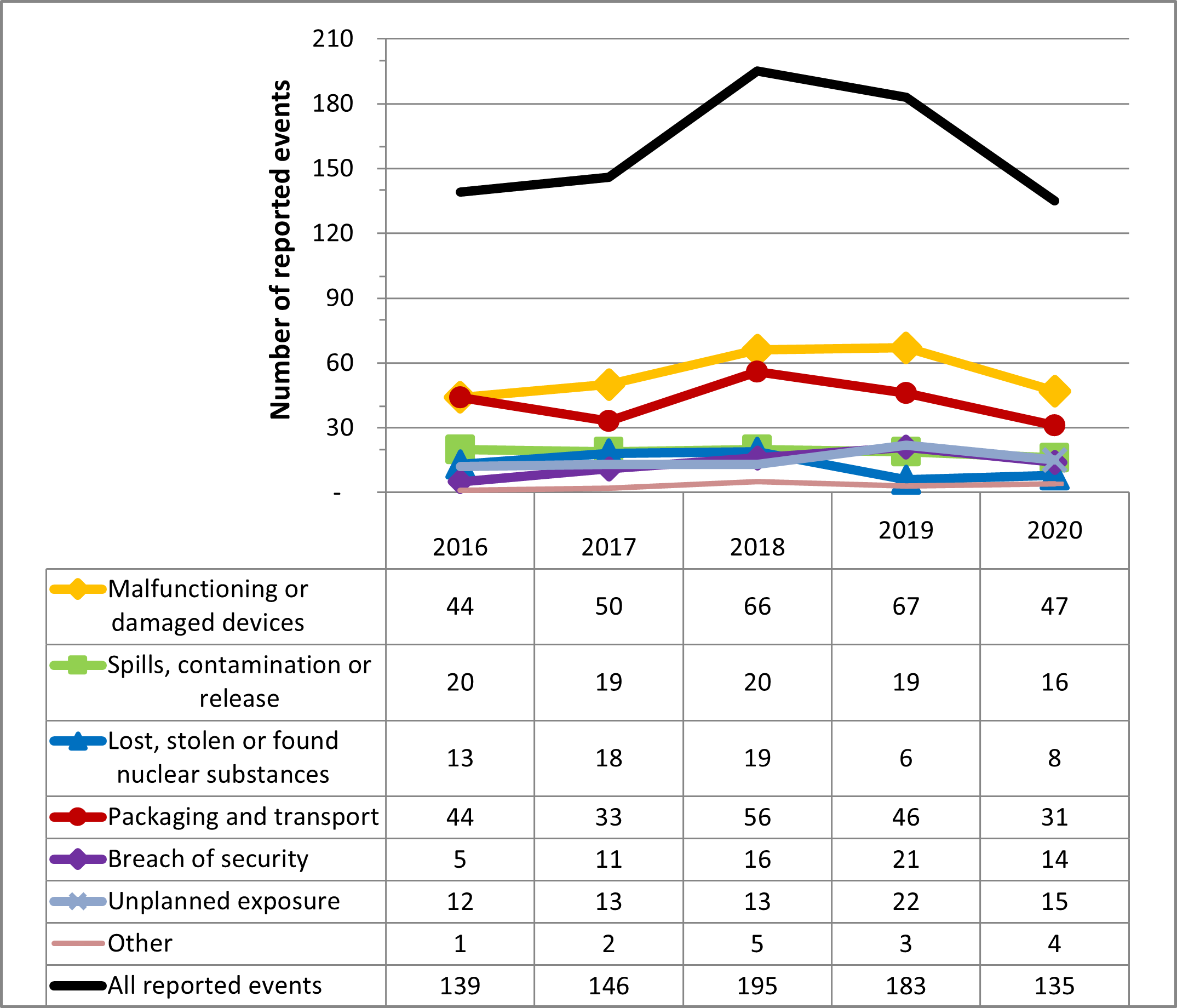

4.0 Reported events

Appendix E describes each event reported in 2020.

Licensees are required to have programs in place to manage unplanned events and accidents. The events that warrant mandatory reporting and the content of the reports are set out in the Nuclear Safety and Control Act (NSCA), its regulations and the licence conditions. CNSC staff review, assess and track all events reported by licensees.

Since 2014, reported events have been rated using the International Nuclear and Radiological Event Scale (INES), a tool for communicating the safety significance of nuclear and radiological events to the public. Note that the scale is not a tool for comparing safety performances among facilities or organizations, but rather for effectively communicating the safety significance of events.

CNSC staff assessed 135 events related to nuclear substances and prescribed equipment in 2020 as seen in appendix E, figure 17. Of these events, 126 were rated as INES level 0 (no safety significance) and 7 as INES level 1 (anomaly).

Of the INES level 1 events, 3 involved doses above the 1 mSv dose limit to non-NEW workers; these were covered in the previous section. The other 4 were related to stolen portable gauges. One of these events involved a portable gauge that was reported stolen by the licensee back in 2013 and was recovered in 2020 after a member of the public found it in a warehouse and notified the CNSC. The CNSC was able to identify the licensee-owner, who was then able to safely recover the portable gauge and confirm that it was in good condition, with both sources in a shielded position. Two events involved the theft of portable gauges that were promptly recovered. The final event involved a portable gauge that was reported stolen while it was stored in a parked vehicle, which has yet to be recovered. The portable gauge contains a Category 4 sealed source, meaning that it is classified as “low risk” and is unlikely to be dangerous.

For all cases of events reported to the CNSC, licensees implemented appropriate response measures to mitigate the impacts of the events and to limit radiation exposure to workers and the public. CNSC staff reviewed the measures and found them to be satisfactory. More information on the events can be found in appendix E.

As noted above, event data related to transport is a more meaningful indicator than licensee performance ratings for the packaging and transport SCA. Out of the 135 events reported in 2020, 31 (23%) were related to transport. For the most part (68%), these events were related to minor motor vehicle accidents (MVAs) (“or fender benders”) where there was no damage to the package being transported and no injury to the driver. None of the transport-related events were considered risk-significant; all were rated as INES level 0. Given the high volume of packages containing radioactive material that are shipped on a regular basis in Canada, the small number of transport events reported in 2020 – all of which were of low risk significance – provide an indicator of the overall level of safety of this activity.

The number of reported events in 2020 is slightly lower than those in the previous 5 years. However, it is generally consistent with typical annual numbers. There was a lull in reported events from March to June 2020, compared to previous years’ monthly event data – this time frame corresponds to lockdowns across the country. The number of events reported stabilized-to-average levels midway through the year, corresponding with some lockdowns being lifted and workers gradually returning to the workplace. The lower number of events observed in 2020 could be related to licensees’ restrictions on their operations during the pandemic. However, a more thorough analysis of data over the next few years will help to determine if the pandemic resulted in lower numbers.

5.0 Stakeholder engagement

The CNSC performs stakeholder engagement and outreach activities, in order to facilitate communication on licensed activities and regulatory expectations between the CNSC and the nuclear substance licensees, the public, and Indigenous communities.

Stakeholder engagement and outreach are critical elements of the CNSC’s regulatory approach. Given the breadth of licensees regulated in the area of nuclear substances, a particular focus is on reaching and engaging with licensee communities, a practice that leads to increased awareness and better understanding of the regulatory process and requirements. CNSC staff leverage a variety of fora to engage with licensees and promote the use of the tools that are developed to support their compliance with regulatory expectations.

In the early stage of the pandemic, CNSC staff conducted outreach activities to ascertain the operating environment of its licensees and to verify that all licensees had maintained measures for the safety and security of their nuclear substances. The CNSC contacted each DNSR licensee individually to ensure communications were maintained during the pandemic, and requested updates related to the status of business activity, alternate contact means, and changes to key persons involved in the licensed activity. Specific information was also sought related to additional training required for workers, and the maintenance of required training related to radiation protection and transportation of dangerous goods.

Other CNSC outreach in 2020 included:

- Regulatory policy discussion – hosted by the CNSC on February 12, on REGDOC‑1.6.2, Developing and Implementing an Effective Radiation Protection Program for Nuclear Substances and Radiation Devices Licences

- DNSR Digest: six issues of the DNSR Digest– containing brief articles of interest to DNSR licensees were distributed by email in 2020; please note the DNSR Digest replaced the former DNSR Newsletter effective August 2020

-

Working groups:

- The Radiography Working Group was hosted by the CNSC in 2020

-

There were 2 meetings with the Canadian Radiation Protection Association (CRPA) working group –an in-person meeting (before the pandemic) and a remote one; topics for such meetings are varied, focusing on items of mutual interest, and are intended to foster open communications between CRPA and the CNSC

- February 14 – in-person discussion on multi modality dose consideration in room approvals, general communication updates and update on regulatory documents

- December 11 – virtual discussion on new Radiation Protection Regulations, comments from CRPA on the 2019 ROR and general discussion of mutual interest

6.0 Conclusion

In 2020, the majority of the inspected licensees were in compliance with the expectations of the SCAs, and all of the enforcement actions taken in 2020 have been closed. Radiation exposure to workers in 2020 continued to be very low and consistent with previous years. For the events reported in 2020, the licensees implemented appropriate responses to address the events, as determined by CNSC staff. CNSC staff continued to host outreach activities with various stakeholders to keep the public, Indigenous communities and licensees informed.

Adapting to the pandemic environment allowed CNSC staff to leverage the use of alternate performance verification activities, such as remote inspections, and in 2020 the mix of remote and onsite inspections was sufficient to maintain regulatory oversight. However, CNSC staff conclude that remote inspections are most appropriate during exceptional circumstances; they will not be the standard moving forward, as the goal is to return to majority in-person inspections when it is appropriate and safe to do so.

Overall, CNSC staff saw no significant changes in the distribution of licences, compliance trending, or doses to workers for any of the sectors covered by this report. Licensees corrected identified items of non-compliance to the satisfaction of CNSC staff. The evaluations of findings for the SCAs, resulting from the CNSC’s comprehensive regulatory oversight of the industry, demonstrate that licensees made acceptable provisions to protect health, safety, security and the environment from the use of nuclear substances and prescribed equipment, and took the measures required to implement Canada’s international obligations. Based on these evaluations, CNSC staff conclude that the use of nuclear substances and prescribed equipment in Canada remains safe and secure.

Appendix A: Regulatory program for the use of nuclear substances

This appendix presents additional regulatory data to complement the information provided in the main part of the document.

A.1 CNSC regulatory effort

| Type of decision | Number of decisions |

|---|---|

| Licensing (issuance of new licences, licence renewals, licence amendments, licence revocations and licence transfers) | 1,484 |

| Certification of prescribed equipment (radiation devices, Class II prescribed equipment and transport packages) | 63 |

| Certification of exposure device operators (EDOs) (issuance of new certification and renewal of certification) | 393 |

| Certification of Class II radiation safety officers (RSOs) | 24 |

| Total | 1,964 |

| Activity | Person-days |

|---|---|

| Licensing | 5,433 |

| Certification | 1,299 |

| Compliance verification | 4,966 |

A.2 Licensing

In 2020, there were 2,079 licences held for the use of nuclear substances and prescribed equipment (table 3). The licensees are located throughout Canada, as indicated in figure 1. Note the difference in the total number of licences in table 3 (2,079) versus figure 1 (2,035); this is because 44 licences were issued to companies headquartered in other countries (primarily the United States), but these companies service prescribed equipment located in Canada.

| Sector | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|

| Medical | 470 | 457 | 436 | 438 | 445 |

| Industrial | 1,308 | 1,287 | 1,259 | 1,228 | 1,207 |

| Academic and research | 208 | 195 | 192 | 187 | 189 |

| Commercial | 254 | 252 | 248 | 237 | 238 |

| Total | 2,240 | 2,191 | 2,135 | 2,090 | 2,079 |

Figure 1: Licensees across Canada using nuclear substances and prescribed equipment

.png/object)

Figure 1: Text version

This map shows the distribution of licensees by sector across Canada.

Yukon: 5 industrial licences

Northwest Territories: 7 industrial licences

Nunavut: 1 industrial licence

British Columbia: 162 industrial licences, 14 academic and research licences, 44 medical licences, 19 commercial licences

Alberta: 291 industrial licences, 32 academic and research licences, 38 medical licences, 13 commercial licences

Saskatchewan: 47 industrial licences, 3 academic and research licences, 11 medical licences, 9 commercial licences

Manitoba: 28 industrial licences, 4 academic and research licences, 13 medical licences, 9 commercial licences

Ontario: 369 industrial licences, 97 academic and research licences, 190 medical licences, 82 commercial licences

Quebec: 209 industrial licences, 36 academic and research licences, 119 medical licences, 54 commercial licences

New Brunswick: 27 industrial licences, 3 academic and research licences, 15 medical licences, 5 commercial licences

Prince Edward Island: 2 industrial licences, 1 academic and research licence, 3 medical licences, 0 commercial licences

Nova Scotia: 30 industrial licences, 4 academic and research licences, 5 medical licences, 3 commercial licences

Newfoundland and Labrador: 27 industrial licences, 4 academic and research licences, 6 medical licences, 1 commercial licence

A.3 Certification of prescribed equipment and transport packages

As seen in table 1, designated officers made 63 decisions related to the certification of prescribed equipment and/or transport packages.

A.4 Certification of exposure device operators

Licensees are required under the Nuclear Substances and Radiation Devices Regulations to permit only CNSC-certified personnel and supervised trainees to use exposure devices containing nuclear substances. In 2020, the CNSC certified 61 new exposure device operators (EDOs) and renewed the certifications of 332 others.

A.5 Certification of Class II radiation safety officers

All licensees that operate Class II nuclear facilities or that service Class II prescribed equipment must have a certified radiation safety officer (RSO) and a qualified temporary replacement. The RSO ensures that licensed activities are conducted safely and that all regulatory expectations are met.

In 2020, the CNSC certified 24 Class II RSOs. No Class II RSOs were decertified in 2020.

A.6 Record of decision – Mississauga Metals and Alloys exemption request

As requested by the Commission, CNSC staff report that, pursuant to paragraph 37(2)(c) of the NSCA, the designated officer (DO) decided to renew Mississauga Metals and Alloys’ (MM&A’s) waste nuclear substance licence. The licence, WNSL-W2-3750.00/2022, is valid from May 1, 2021 to February 28, 2022, unless otherwise suspended, amended, revoked, replaced or transferred.

The DO recognized that the Commission has granted MM&A a temporary exemption from the Canadian Nuclear Safety Commission Cost Recovery Fees Regulations, based in part on the understanding that the licensee has committed to providing full payment of arrears in accordance with the Licence Activity Plan (which includes a payment plan), submitted as part of its application for a licence. A licence condition has been added to ensure that MM&A complies with the Licensed Activity Plan, and the elements of this plan have been included in appendix A of the MM&A licence. The licence condition states: “The licensee shall comply with the arrears payment schedule as set out in Appendix A of this licence.” CNSC staff will monitor MM&A’s payments of its arrears and will take appropriate action to respond to any non-compliance.

As part of its application for the renewal of its licence, MM&A submitted a revised radiation safety manual and demonstrated that it has the qualifications to implement the radiation safety program. CNSC staff determined that this satisfies the conditions to close the order that had been raised further to the November 2019 compliance inspection.

Appendix B: Compliance performance

As previously noted in the body of the report, it is important to keep in mind, when interpreting the data presented, that the decreased number of inspections due to the COVID-19 pandemic affected the performance metric sample size. Since the sample size in 2020 was much smaller than in previous years, it is difficult to compare results year over year. Therefore, the reader should not place too much emphasis on any apparent trending when interpreting performance results.

B.1 Management system

For the management system SCA, 96% of the licensees inspected ensured that adequate processes and programs were in place to achieve their safety objectives (figures 2 and 3). There were no unacceptable ratings in this SCA.

For any below-expectations ratings, CNSC staff ensured that licensees took appropriate corrective actions.

Figure 2: Inspection ratings for management system, 2016 to 2020

.png/object)

Figure 2: Text version

The graph shows the percentage of management systems inspections that met expectations, that were below expectations and that were unacceptable. The table shows the total number of management systems inspections that met expectations, that were below expectations and that were unacceptable.

| 2016 | 2017 | 2018 | 2019 | 2020 | |

|---|---|---|---|---|---|

| Meets expectations | 1,265 (98%) | 840 (97%) | 843 (97%) | 739 (97%) | 321 (96%) |

| Below expectations | 27 (2%) | 23 (3%) | 29 (3%) | 22 (3%) | 14 (4%) |

| Unacceptable | 2 (0.2%) | 1 (0.2%) | 0 (0%) | 3 (0.4%) | 0 (0%) |

| Total number of inspections | 1,294 | 864 | 872 | 764 | 335 |

Figure 3: Sector-by-sector comparison of inspection ratings meeting expectations for management system, 2016 to 2020

.png/object)

Figure 3: Text version

The graph shows a sector-to-sector comparison of inspection ratings meeting expectations as a percentage of inspections performed for the management system SCA, from 2016 to 2020. The table shows the number of inspections for the management system SCA by sector.

| Number of Inspections | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|

| Medical | 207 (96%) | 106 (96%) | 110 (94%) | 155 (95%) | 44 (92%) |

| Industrial | 901 (98%) | 605 (98%) | 608 (97%) | 475 (98%) | 254 (96%) |

| Academic and Research | 73 (975) | 71 (97%) | 85 (99%) | 73 (99%) | 9 (100%) |

| Commercial | 84 (97%) | 58 (94%) | 40 (98%) | 36 (97%) | 14 (100%) |

| All sectors combined | 1,265 (98%) | 840 (97%) | 843 (99%) | 739 (97%) | 321 (97%) |

B.2 Operating performance

For the operating performance SCA, 83% of the licensees inspected ensured that adequate processes and programs were in place to achieve their safety objectives (figures 4 and 5). There were no unacceptable ratings in this SCA.

For any below-expectations ratings, CNSC staff ensured that licensees took appropriate corrective actions.

Figure 4: Inspection performance for operating performance, 2016 to 2020

.png/object)

Figure 4: Text version

The graph shows the percentage of operating performance inspections that met expectations, that were below expectations and that were unacceptable. The table shows the total number of operating performance inspections that met expectations, that were below expectations and that were unacceptable.

| 2016 | 2017 | 2018 | 2019 | 2020 | |

|---|---|---|---|---|---|

| Meets expectations | 1,151 (87%) | 747 (85%) | 747 (84%) | 672 (86%) | 292(83%) |

| Below expectations | 161 (12%) | 128 (15%) | 144 (16%) | 110 (14%) | 61 (17%) |

| Unacceptable | 5 (0.4%) | 8 (1%) | 4 (0.4%) | 2 (0.3%) | 0 (0%) |

| Total number of inspections | 1,317 | 883 | 895 | 784 | 353 |

Figure 5: Sector-by-sector comparison of inspections meeting expectations for operating performance, 2016 to 2020

.png/object)

Figure 5: Text version

The graph shows a sector-to-sector comparison of inspection ratings meeting expectations as a percentage of inspections performed for the operating performance SCA, from 2016 to 2020. The table shows the number of inspections for the operating performance SCA by sector.

| Number of Inspections | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|

| Medical | 201 (88%) | 100 (86%) | 96 (77%) | 155 (88%) | 41 (80%) |

| Industrial | 792 (86%) | 511 (82%) | 528 (83%) | 409 (85%) | 225 (84%) |

| Academic and Research | 74 (91%) | 73 (97%) | 79 (88%) | 70 (95%) | 9 (90%) |

| Commercial | 84 (92%) | 63 (94%) | 44 (92%) | 38(89%) | 17 (94%) |

| All sectors combined | 1,151 (87%) | 747 (85%) | 747 (84%) | 672 (86%) | 292 (83%) |

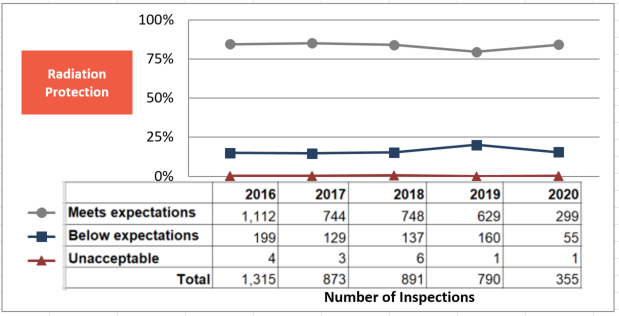

B.3 Radiation protection

For the radiation protection SCA, 84% of the licensees inspected ensured that adequate processes and programs were in place to achieve their safety objectives (figures 6 and 7).

One industrial licensee received an unacceptable rating in radiation protection. The licensee was issued an order. The licensee has complied with the terms of the order and put corrective measures in place to address all items of non-compliance found during the routine Type II inspection that led to the issuance of the order. More details about the order (#1212) can be found in table 17 of appendix C. CNSC staff were satisfied with the corrective actions put in place by the licensee and the order is now closed.

For any below-expectations ratings, CNSC staff ensured that licensees took appropriate corrective actions.

Figure 6: Inspection performance for radiation protection, 2016 to 2020

Figure 6: Text version

The graph shows the percentage of radiation protection inspections that met expectations, that were below expectations and that were unacceptable. The table shows the total number of radiation protection inspections that met expectations, that were below expectations and that were unacceptable.

| 2016 | 2017 | 2018 | 2019 | 2020 | |

|---|---|---|---|---|---|

| Meets expectations | 1,112 (85%) | 744 (85%) | 748 (84%) | 629 (80%) | 299 (84%) |

| Below expectations | 199 (15%) | 129 (15%) | 137 (15%) | 160 (20%) | 55 (16%) |

| Unacceptable | 4 (0.3%) | 3 (0.3%) | 6 (0.7%) | 1 (0.1%) | 1 (0.3%) |

| Total number of inspections | 1,315 | 873 | 891 | 790 | 355 |

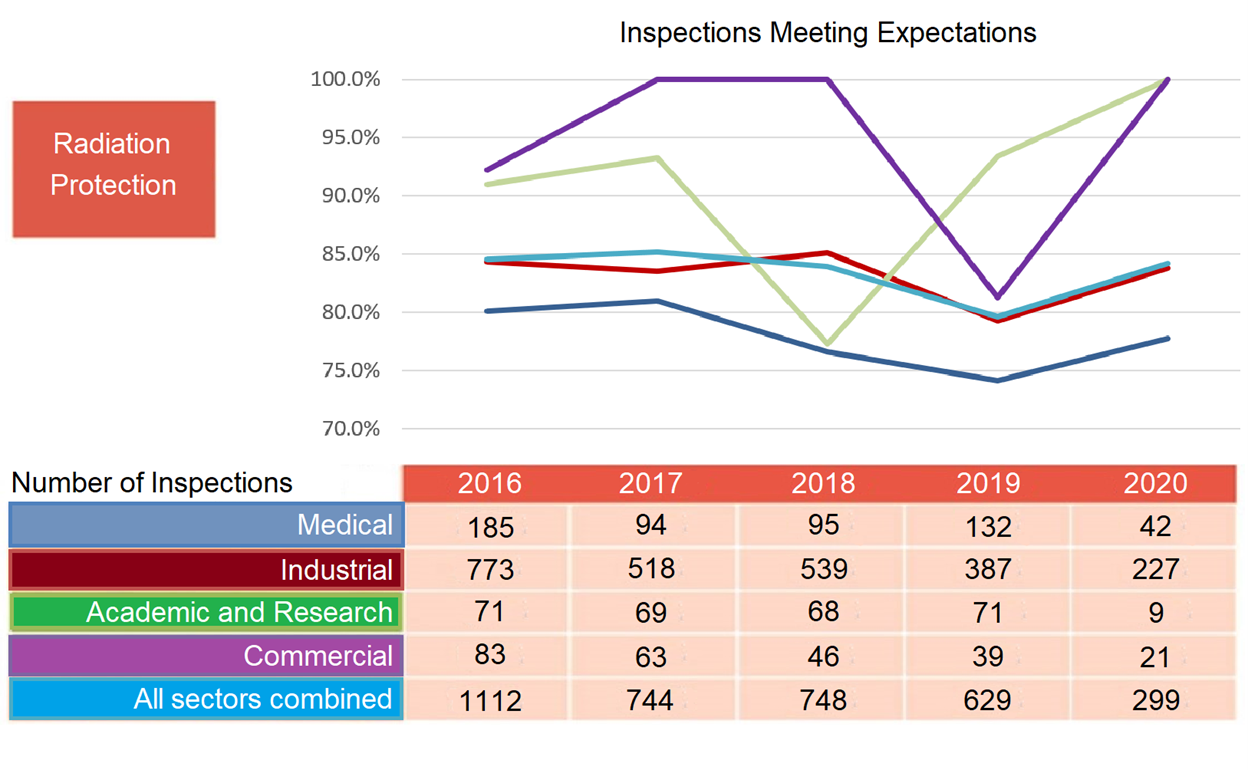

Figure 7: Sector-by-sector comparison of inspections meeting expectations for radiation protection, 2016 to 2020

Figure 7: Text version

The graph shows a sector-to-sector comparison of inspection ratings meeting expectations as a percentage of inspections performed for the radiation protection SCA, from 2016 to 2020. The table shows the number of inspections for the radiation protection SCA by sector.

| Number of Inspections | 2016 | 2017 | 2018 | 2019 | 2020 |

| Medical | 185 (80%) | 94 (81%) | 95 (77%) | 132 (74%) | 42 (82%) |

| Industrial | 773 (84%) | 518 (84%) | 539 (85%) | 387 (80%) | 227 (85%) |

| Academic and Research | 71 (91%) | 69 (93%) | 68 (77%) | 71 (96%) | 9 (90%) |

| Commercial | 83 (92%) | 63 (100%) | 46 (100%) | 39(81%) | 21 (100%) |

| All sectors combined | 1,112 (85%) | 744 (85%) | 748 (84%) | 629 (80%) | 299 (84%) |

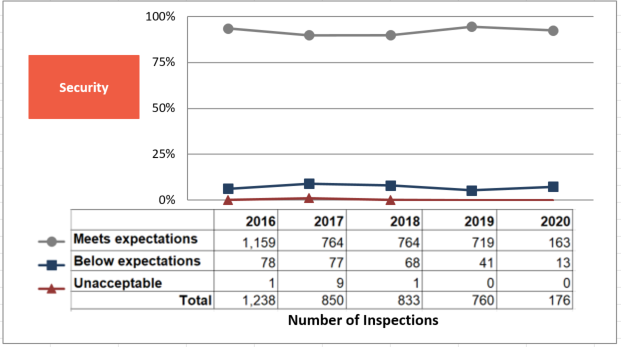

B.4 Security

For the security SCA, 93% of the licensees inspected ensured that adequate processes and programs were in place to achieve their safety objectives (figures 8 and 9). None of the licensees received an unacceptable rating for the security SCA.

For any below-expectations ratings, CNSC staff ensured that licensees took appropriate corrective actions.

Figure 8: Inspection performance for security, 2016 to 2020

Figure 8: Text version

The graph shows the percentage of security inspections that met expectations, that were below expectations and that were unacceptable. The table shows the total number of security inspections that met expectations, that were below expectations and that were unacceptable.

| 2016 | 2017 | 2018 | 2019 | 2020 | |

| Meets expectations | 1,159 (94%) | 764 (90%) | 764 (92%) | 719 (95%) | 163 (93%) |

| Below expectations | 78 (6%) | 77 (9%) | 68 (8%) | 41 (5%) | 13 (7%) |

| Unacceptable | 1 (0.1%) | 9 (1.1%) | 1 (0.1%) | 0 (0%) | 0 (0%) |

| Total number of inspections | 1,238 | 850 | 833 | 760 | 176 |

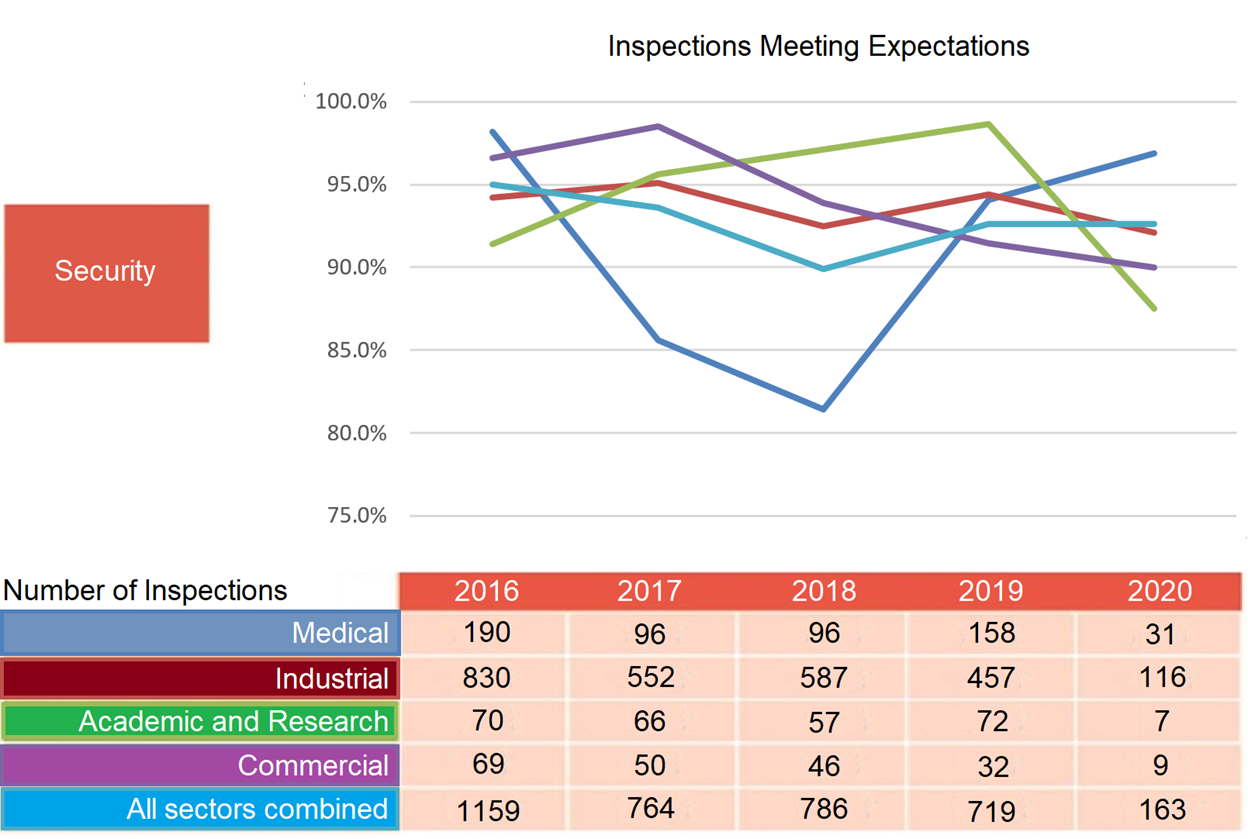

Figure 9: Sector-by-sector comparison of inspections meeting expectations for security, 2016 to 2020

Figure 9: Text version

The graph shows a sector-to-sector comparison of inspection ratings meeting expectations as a percentage of inspections performed for the security SCA, from 2016 to 2020. The table shows the number of inspections for the security SCA by sector.

| Number of Inspections | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|

| Medical | 190 (86%) | 96 (81%) | 96 (91%) | 158 (94%) | 31 (94%) |

| Industrial | 830 (95%) | 552 (93%) | 587 (94%) | 457 (94%) | 116 (95%) |

| Academic and Research | 70 (96%) | 66 (97%) | 57 (79%) | 72 (99%) | 7 (100%) |

| Commercial | 69 (99%) | 50 (94%) | 46 (93%) | 32 (91%) | 9 (90%) |

| All sectors combined | 1,159 (94%) | 764 (90%) | 786 (94%) | 719 (95%) | 163 (93%) |

B.5 Inspection rating, by sector

B.5.1 Medical sector

Tables 4 to 7 in this section show the inspection performance of licensees in the medical sector. The performance of the subsectors is shown for the years 2016 to 2020 as a percentage of the inspections that received satisfactory ratings for the SCA, together with the total number of inspections where performance in that SCA was assessed. The number of inspections shown in the “Entire medical sector” row is the aggregate for the entire sector, including subsectors not highlighted.

A breakdown by subsector is not provided for the security SCA, given the potentially sensitive information associated with that SCA.

Table 4: Management system: Percentage of inspections meeting expectations (and number of inspections conducted) for the medical sector and selected subsectors within the sector, 2016 to 2020

| SCA | Subsector or sector | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|

| Management system | Nuclear medicine |

96%

(174) |

98%

(91) |

96%

(103) |

95%

(103) |

94%

(47) |

| Radiation therapy |

67%

(10) |

82%

(11) |

50%

(6) |

100%

(4) |

0%

(1) |

|

| Veterinary nuclear medicine |

100%

(9) |

100%

(4) |

100%

(4) |

75%

(4) |

(0) | |

| Entire medical sector |

96%

(216) |

97%

(110) |

94%

(117) |

95%

(163) |

92%

(48) |

Table 5: Operating performance: Percentage of inspections meeting expectations (and number of inspections conducted) for the medical sector and selected subsectors within the sector, 2016 to 2020

| SCA | Subsector or sector | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|

Operating Performance |

Nuclear medicine |

86%

(184) |

86%

(90) |

77%

(104) |

87%

(155) |

77%

(48) |

| Radiation therapy |

92%

(24) |

89%

(18) |

67%

(12) |

100%

(21) |

100%

(2) |

|

| Veterinary nuclear medicine |

100%

(9) |

100%

(4) |

100%

(4) |

100%

(3) |

100%

(1) |

|

| Entire medical sector |

88%

(228) |

87%

(116) |

77%

(124) |

88%

(176) |

77%

(51) |

Note: Inspections for the nuclear medicine subsector were prioritized based on licensees that had not been recently inspected. The majority of completed inspections for this subsector were conducted onsite and at the beginning of the year, prior to the pandemic. The licensees inspected during that period were high priority, and this led to an increase in findings. The smaller number of inspections completed in 2020 and the higher number of findings led to the overall decrease in performance for this SCA.

Table 6: Radiation protection: Percentage of inspections meeting expectations (and number of inspections conducted) for the medical sector and selected subsectors within the sector, 2016 to 2020

| SCA | Subsector or sector | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|

| Radiation Protection | Nuclear medicine |

77%

(186) |

75%

(89) |

74%

(104) |

70%

(155) |

73%

(48) |

| Radiation therapy |

100%

(24) |

100%

(19) |

100%

(12) |

100%

(13) |

100%

(2) |

|

| Veterinary nuclear medicine |

67%

(9) |

100%

(4) |

50%

(4) |

100%

(3) |

100%

(1) |

|

| Entire medical sector |

80%

(231) |

81%

(116) |

77%

(124) |

74%

(178) |

76%

(51) |

Note: Inspections for the nuclear medicine subsector were prioritized based on licensees that had not been recently inspected. The majority of completed inspections for this subsector were conducted onsite and at the beginning of the year, prior to the pandemic. The licensees inspected during that period were high priority, and this led to an increase in findings. The smaller number of inspections completed in 2020 and the higher number of findings led to the overall decrease in performance for this SCA. However, the areas identified as needing major improvements in 2019 had positive outcomes in 2020, probably due to the outreach activities performed.

Table 7: Security: Percentage of inspections meeting expectations (and number of inspections conducted) for the medical sector, 2016 to 2020

| SCA | Subsector or sector | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|

| Security | Medical sector |

86%

(222) |

81%

(118) |

91%

(119) |

94%

(168) |

97%

(33) |

B.5.2 Industrial sector

Tables 8 to 11 in this appendix show the inspection performance of licensees in the industrial sector. The performance of the subsectors is shown for the years 2016 to 2020 as a percentage of the inspections that received satisfactory ratings for the SCA, together with the total number of inspections where performance in that SCA was assessed. The number of inspections for the “Entire industrial sector” row is the aggregate for the entire sector, including subsectors not highlighted.

A breakdown by subsector is not provided for the security SCA, given the potentially sensitive information associated with that SCA.

Table 8: Management system: Percentage of inspections meeting expectations (and number of inspections conducted) for the industrial sector and selected subsectors within the sector, 2016 to 2020

| SCA | Subsector or sector | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|

| Management system | Portable gauge |

98%

(443) |

99%

(303) |

98%

(321) |

100%

(215) |

98%

(92) |

| Fixed gauge |

100%

(205) |

94%

(130) |

94%

(112) |

94%

(124) |

94%

(94) |

|

| Industrial radiography |

97%

(201) |

96%

(136) |

96%

(138) |

98%

(114) |

98%

(66) |

|

| Oil-well logging |

100%

(48) |

100%

(42) |

98%

(43) |

100%

(24) |

89%

(9) |

|

| Entire industrial sector |

98%

(916) |

98%

(620) |

97%

(608) |

98%

(487) |

96%

(261) |

A significant reduced activity in the oil-well logging subsector, unrelated to the pandemic, led to a large decrease in locations storing and using nuclear substances, resulting in reduced number of planned inspections in 2020. While compliance in the subsector was similar to past years, a single slightly lower performer combined with the low number of performed inspections led to a decrease in performance for this subsector.

Table 9: Operating performance: Percentage of inspections meeting expectations (and number of inspections conducted) for the industrial sector and selected subsectors within the sector, 2016 to 2020

| SCA | Subsector or sector | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|

Operating Performance |

Portable gauge |

87%

(439) |

82%

(305) |

86%

(326) |

82%

(216) |

82%

(98) |

| Fixed gauge |

77%

(205) |

70%

(136) |

68%

(111) |

73%

(124) |

71%

(94) |

|

| Industrial radiography |

94%

(199) |

89%

(116) |

88%

(138) |

93%

(114) |

98%

(66) |

|

| Oil-well logging |

90%

(48) |

93%

(42) |

86%

(44) |

100%

(24) |

100%

(9) |

|

| Entire industrial sector |

86%

(917) |

82%

(625) |

83%

(633) |

83.9%

(484) |

82%

(267) |

Note: Inspections for the fixed gauge subsector were prioritized based on licensees that had not been recently inspected, licensees that were individually selected based on lower past compliance results, and licensees with specific conditions in their licences permitting specific activities with a greater risk to the safety of workers. This subsector grading has similar low results in the past few years due to the way compliance is verified in assessing operating performance. A single finding related to a licensee’s procedure will generally lead to a negative impact on the overall performance.

Table 10: Radiation protection: Percentage of inspections meeting expectations (and number of inspections conducted) for the industrial sector and selected subsectors within the sector, 2016 to 2020

| SCA | Subsector or sector | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|

| Radiation Protection | Portable gauge |

84%

(442) |

82%

(306) |

84%

(326) |

74%

(216) |

83%

(98) |

| Fixed gauge |

78%

(205) |

80%

(132) |

77%

(111) |

73%

(124) |

82%

(94) |

|

| Industrial radiography |

92%

(198) |

90%

(130) |

91%

(138) |

92%

(114) |

86%

(66) |

|

| Oil-well logging |

79%

(48) |

86%

(42) |

91%

(44) |

92%

(24) |

89%

(9) |

|

| Entire industrial sector |

84%

(916) |

84%

(620) |

85%

(633) |

79%

(483) |

84%

(267) |

Note: Inspections for the industrial radiography subsector were prioritized based on licensees that had not recently been inspected, licensees that were individually selected based on lower past compliance results, or situations where a follow-up compliance activity was deemed necessary. Most onsite inspections were conducted in the first months of 2020. Findings with greater negative impacts on the grading were also observed in those months. This corresponds to the period when most of the inspections were prioritized based on licensees with lower performance in their compliance history. A low number of inspections performed in the remaining months, combined with this history of lower performing licensees inspected at the beginning of the year, resulted in a lower rating in 2020.

Table 11: Security: Percentage of inspections meeting expectations (and number of inspections conducted) for the industrial sector, 2016 to 2020

| SCA | Subsector or sector | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|

| Security | Industrial sector |

95%

(873) |

91%

(610) |

94%

(624) |

94%

(484) |

92%

(122) |

B.5.3 Academic and research sector

Tables 12 to 15 in this appendix show the inspection performance of licensees in the academic and research sector. The performance of the subsectors is shown for the years 2016 to 2020 as a percentage of the inspections that received satisfactory ratings for the SCA, together with the total number of inspections for which performance in that SCA was assessed. The number of inspections for the “Entire academic and research sector” row is the aggregate for the entire sector, including subsectors not highlighted.

A breakdown by subsector is not provided for the security SCA, given the potentially sensitive information associated with that SCA.

Table 12: Management system: Percentage of inspections meeting expectations (and number of inspections conducted) for the academic and research sector and selected subsector within the sector, 2016 to 2020

| SCA | Subsector or sector | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|

| Management system | Laboratory studies and consolidated use |

97%

(71) |

97%

(73) |

99%

(84) |

99%

(74) |

100%

(9) |

| Entire academic and research sector |

97%

(75) |

97%

(73) |

99%

(86) |

99%

(74) |

100%

(9) |

Table 13: Operating performance: Percentage of inspections meeting expectations (and number of inspections conducted) for the academic and research sector and selected subsector within the sector, 2016 to 2020

| SCA | Subsector or sector | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|

| Operating performance | Laboratory studies and consolidated use |

92%

(75) |

97%

(74) |

88%

(86) |

95%

(74) |

89%

(9) |

| Entire academic and research sector |

91%

(81) |

97%

(75) |

88%

(90) |

95%

(74) |

90%

(10) |

Table 14: Radiation protection: Percentage of inspections meeting expectations (and number of inspections conducted) for the academic and research sector and selected subsector within the sector, 2016 to 2020

| SCA | Subsector or sector | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|

| Radiation protection | Laboratory studies and consolidated use |

92%

(75) |

97%

(74) |

88%

(86) |

93%

(74) |

100%

(10) |

| Entire academic and research sector |

91%

(81) |

97%

(75) |

88%

(90) |

93%

(74) |

100%

(10) |

Table 15: Security: Percentage of inspections meeting expectations (and number of inspections conducted) for the academic and research sector, 2016 to 2020

| SCA | Subsector or sector | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|

| Security | Academic and research sector |

96%

(73) |

96%

(69) |

79%

(72) |

99%

(73) |

100%

(7) |

B.5.4 Commercial sector

Table 16 shows the inspection performance of licensees in the commercial sector. The performance of the sectors is shown for the years 2016 to 2020 as a percentage of the inspections that received satisfactory ratings for the SCA, together with the total number of inspections for which performance in that SCA was assessed. The number of inspections for the commercial sector is the aggregate for the entire sector.

Due to the small number of inspections in each subsector, a breakdown by subsector is not provided. Identifying trends would be difficult in subsectors due to the low number of licensees in many of them.

Table 16: Inspection performance for the commercial sector, 2016 to 2020

| SCA | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|

| Management system |

97%

(87) |

93%

(62) |

97%

(41) |

97%

(40) |

100%

(14) |

| Operating performance |

92%

(91) |

94%

(67) |

92%

(48) |

89%

(36) |

94%

(18) |

| Radiation protection |

92%

(90) |

95%

(63) |

100%

(46) |

83%

(48) |

100%

(21) |

| Security |

99%

(70) |

94%

(53) |

93%

(41) |

91%

(35) |

90%

(10) |

Appendix C: Enforcement actions issued in 2020

As DNSR completed roughly half the typical number of inspections per year, it was also observed that enforcement actions issued were also roughly half the typical number issued, when compared to numbers in 2019. Although affected by many variables, enforcement actions tend to be issued as a result of inspections; as such, fewer inspections typically result in fewer enforcement actions.

In 2020, CNSC staff issued 4 orders and 2 administrative monetary penalties (AMPs) to licensees. Most of the enforcement actions were issued to licensees in the industrial sector, consistent with previous years. A list of orders issued is included in table 17. A list of AMPs issued is included in table 18.

All enforcement actions are closed and the CNSC is satisfied that the licensees have addressed the conditions of the orders/AMPs.

Figure 10: Sector-by-sector comparison of enforcement actions issued, 2016 to 2020

Figure 10: Text version

This figure shows an annual sector-by-sector comparison of enforcement actions issued, for the period 2016 to 2020.

| 2016 | 2017 | 2018 | 2019 | 2020 | |

|---|---|---|---|---|---|

| Medical | 1 | 0 | 1 | 0 | 0 |

| Industrial | 18 | 23 | 14 | 9 | 4 |

| Academic and research | 0 | 0 | 0 | 0 | 0 |

| Commercial | 3 | 1 | 1 | 4 | 2 |

| All sectors combined | 22 | 24 | 16 | 13 | 6 |

The number of enforcement actions (Orders and AMPs) issued to the medical sector was 1 in 2016, 0 in 2017, 1 in 2018, 0 in 2019, and 0 in 2020.

The number of enforcement actions (Orders and AMPs) issued to the industrial sector was 18 in 2016, 23 in 2017, 14 in 2018, 9 in 2019, and 4 in 2020.

The number of enforcement actions (Orders and AMPs) issued to the academic and research sector was 0 in 2016, 0 in 2017, 0 in 2018, 0 in 2019, and 0 in 2020.

The number of enforcement actions (Orders and AMPs) issued to the commercial sector was 3 in 2016, 1 in 2017, 1 in 2018, 4 in 2019, and 2 in 2020.

The number of enforcement actions (Orders and AMPs) issued to all sectors combined was 22 in 2016, 24 in 2017, 16 in 2018, 13 in 2019, and 6 in 2020.

Table 17: Orders issued in 2020

| Issue date (2020) | Order # | Location | Licensee | Subsector, Sector | Licensee response | Closure date (2020) |

|---|---|---|---|---|---|---|

| January 16, 2020 | 1227 | 108 Maplecrete Road, Concord, ON L4K 1A4 | Medagh Industrial Recycling Ltd | 880, industrial | The licensee has complied with the terms of the order and transferred their single radiation device to a servicing company authorized to possess the device. | February 3, 2020 |

| February 20, 2020 | 1212 |

441 Esna Park Drive Unit 19 Markham, ON L3R 1H7 |

Edward Wong & Associates | 811, industrial | The licensee has complied with the terms of the order and put corrective measures in place to address all items of non-compliance found during the routine Type II inspection that led to the issuance of the order. | April 16, 2020 |

| March 10, 2020 | 0550 |

300 Prince Philip Drive St. John’s, NL A1B 3V6 |

Eastern Regional Health Authority | 516, Commercial | The licensee has complied with the terms of the order and put corrective measures in place to address all items of non-compliance found during the routine Type II inspection that led to the issuance of the order. | June 5, 2020 |

| October 30, 2020 | 0841 |

4929 7th Line, Unit 2 Rockwood, ON N0B 2K0 |

Eric Haugen | 826, Commercial | The CNSC took additional enforcement action to arrange the seizure and safe storage of all radioactive material possessed and stored by Kodiak Quality Control Ltd. The order was closed once those actions were completed. | December 3, 2020 |

Table 18: Administrative monetary penalties issued in 2020

| Issue date (2020) | Licensee | Amount | AMP description |

|---|---|---|---|

| October 20, 2020 | Interior Testing Services | $1,000 | A portable gauge was shipped by the licensee with the shutter fully open, allowing higher levels of radiation exposure outside the package. This event violated IAEA Regulations related to shipment, labelling and packaging in accordance with the Packaging and Transport of Nuclear Substances Regulations, 2015. |

| March 20, 2020 | Kodiak Quality Control Ltd. | $2,770 | On November 30, 2020, the CNSC arranged the seizure and safe storage of all radioactive material possessed and stored by Kodiak Quality Control Ltd., a company based in Rockwood, Ontario. The company previously held a CNSC licence, which expired on October 31, 2020, that authorized it to possess, transfer, export and store nuclear substances and prescribed equipment for distribution purposes. |

Appendix D: Doses to workers

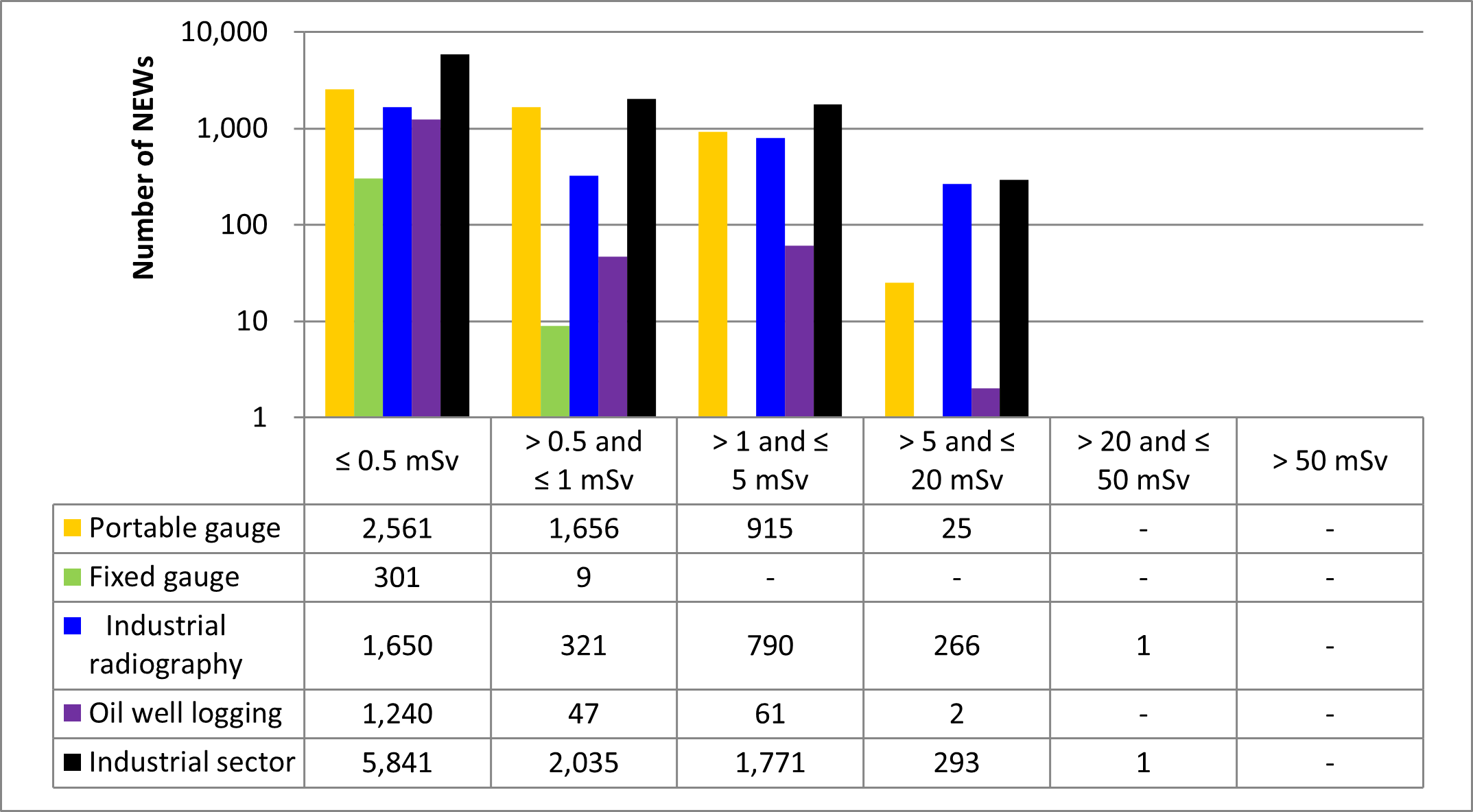

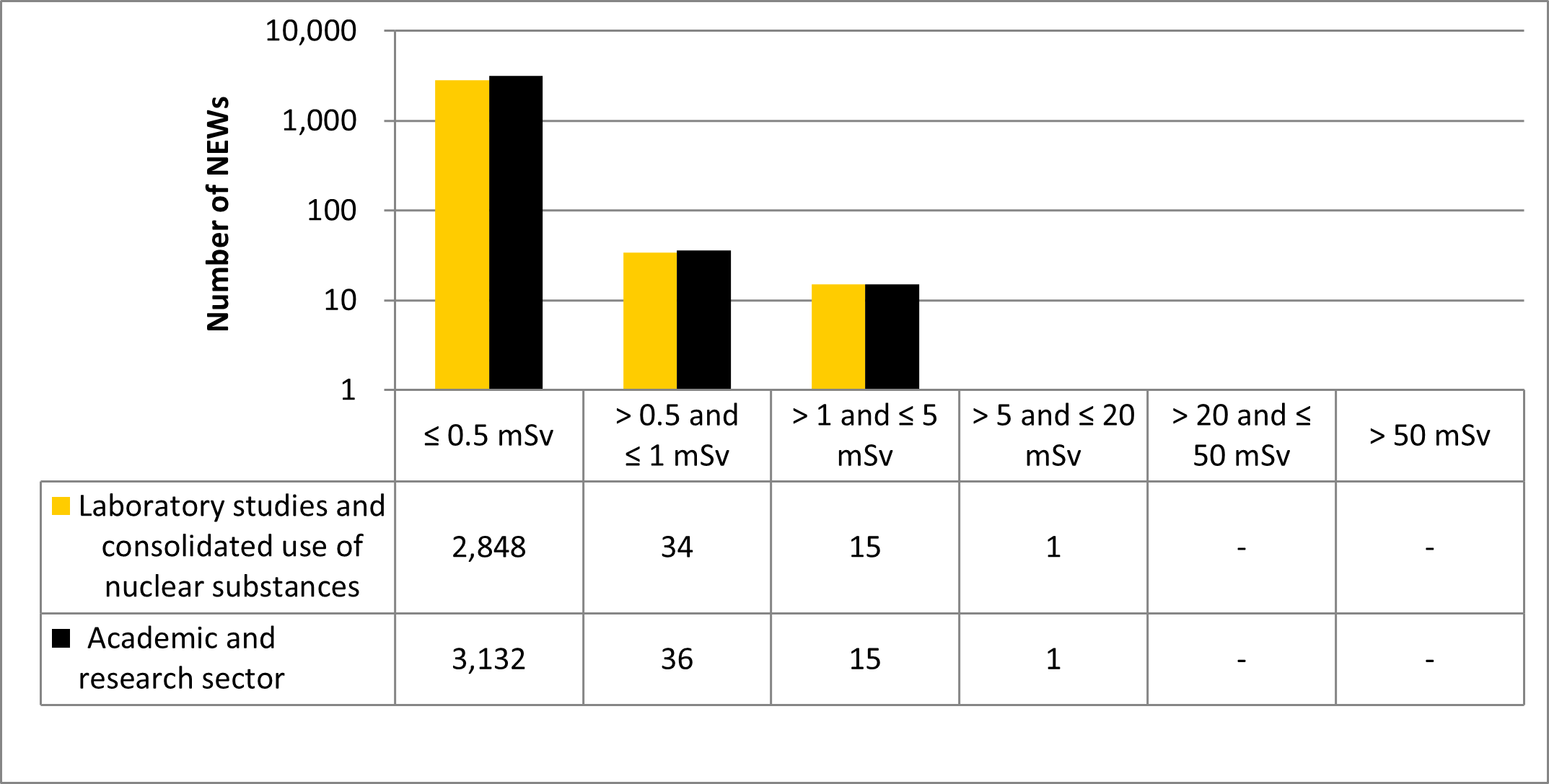

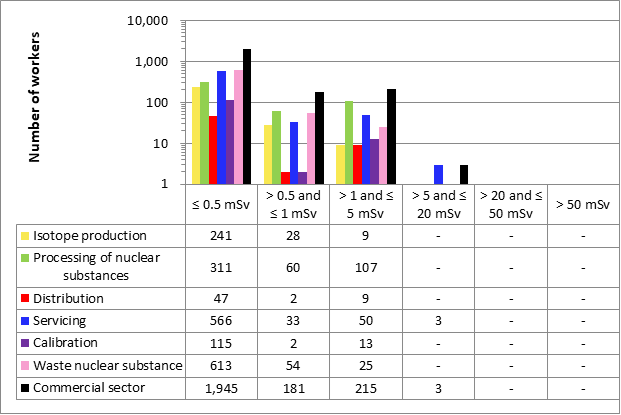

A total of 58,967 workers in the 4 sectors were monitored for occupational doses in 2020. Of those workers, 22,861 were nuclear energy workers (NEWs). The differences in doses to workers among sectors reflect the nature of the various activities within those sectors. Figure 11 shows the doses received by the 22,861 NEWs monitored in 2020, while figure 12 shows the doses to NEWs from 2016 to 2020.

Figure 11: Sector-by-sector comparison of annual effective doses to all NEWs reported by licensees in 2020

Figure 11: Text version

This figure shows a sector-by-sector comparison of the annual effective doses to all NEWs reported by licensees in 2020. The table shows the number of NEWs in each dose category by sector.

| Less than or equal to 0.5 mSv | Greater than 0.5 and less than or equal to 1 mSv | Greater than 1 and less than or equal to 5 mSv | Greater than 5 and less than or equal to 20 mSv | Greater than 20 and less than or equal to 50 mSv | Greater than 50 mSv | |

|---|---|---|---|---|---|---|

| Medical | 5,133 | 565 | 1,599 | 112 | 0 | 0 |

| Industrial | 5,841 | 2,035 | 1,771 | 293 | 1 | 0 |

| Academic and Research | 3,132 | 36 | 15 | 1 | 0 | 0 |

| Commercial | 1,945 | 181 | 215 | 3 | 0 | 0 |

Figure 12: Text version