Regulatory Oversight Report for Uranium Mines, Mills, Historic and Decommissioned Sites in Canada: 2017

Clear Language Summary

The Regulatory Oversight Report for Uranium Mines, Mills, Historic and Decommissioned Sites in Canada: 2017 provides information about the CNSC’s work to ensure the safety and protection of people and the environment around uranium mines and mills across Canada, particularly in Saskatchewan. The 2017 report also includes a summary of the CNSC’s work to demonstrate that historic and decommissioned mines in Canada remain safe and pose no risk to the health and safety of the environment or people.

Uranium mines and mills – Saskatchewan

Overall, the uranium mines and mills in Saskatchewan continued to operate safely in 2017, and there were no releases that could have harmed human health or the environment. The country foods and water surrounding these sites remains safe for consumption.

The following uranium mines and mills in Saskatchewan are covered in the 2017 report:

- Cigar Lake – operating uranium mine

- McArthur River – operating uranium mine

- Rabbit Lake – shut-down uranium mine and mill

- Key Lake – operating uranium mill

- McClean Lake – operating uranium mill

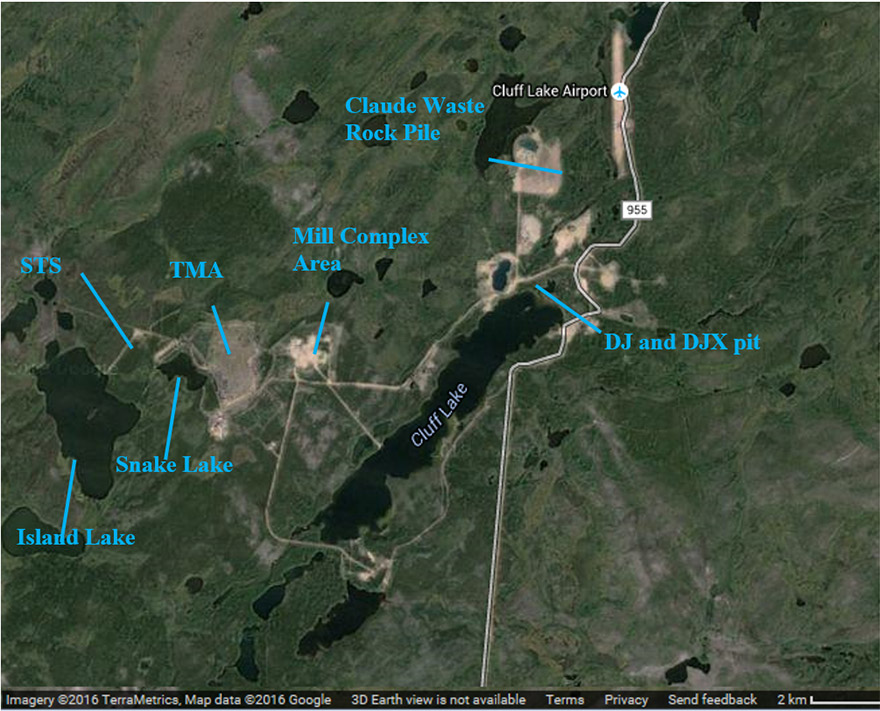

- Cluff Lake – decommissioned uranium mine and mill

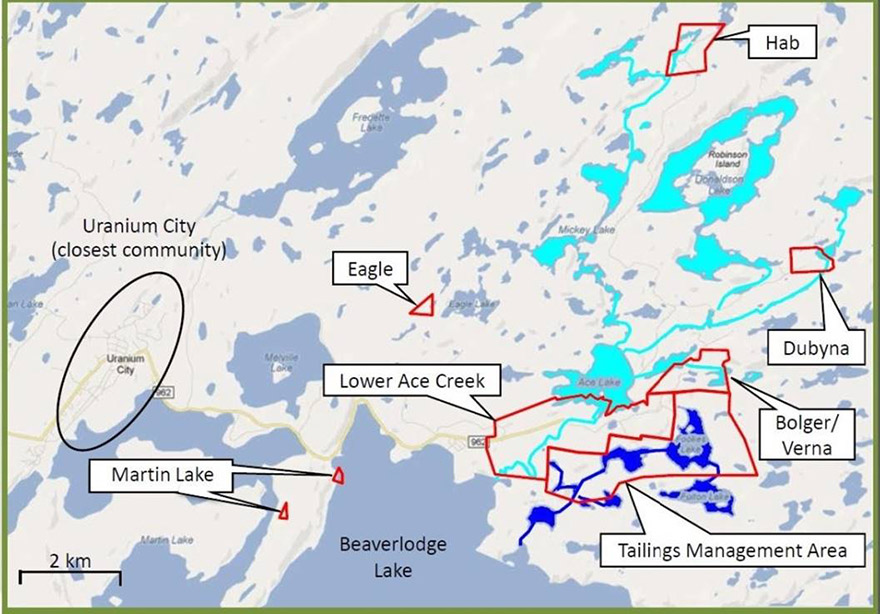

- Beaverlodge – decommissioned historic uranium mine and mill

- Gunnar – decommissioned historic uranium mine, which is undergoing active remediation

- Lorado – decommissioned historic uranium mine, which is undergoing active remediation

During 2017, the operations at all of these sites remained safe. In summary:

- Workers at each site were safe and properly protected.

- There were no releases that could have harmed the environment or health and safety of people.

- All of the water released from the site was safe.

- Airborne radiation was not increased as a result of these sites.

- Fish and plants were safe to eat.

- There were no events that affected the environment or the people nearby.

Uranium mines and mills – Northwest Territories

The following decommissioned historic uranium mines and mills in the Northwest Territories are covered in the 2017 report:

- Rayrock

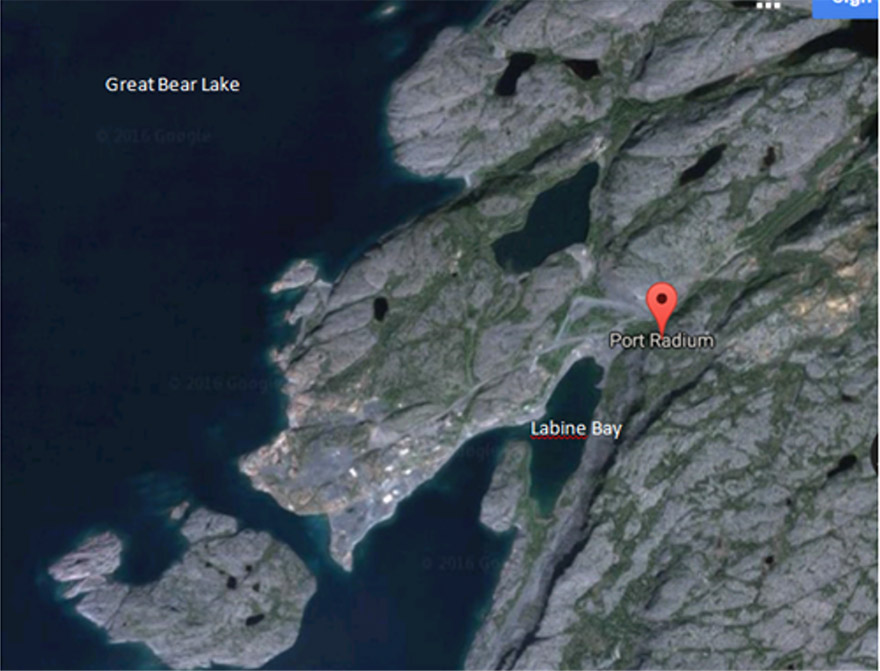

- Port Radium

Work is continuing at these sites to ensure that they remain safe and there is proper protection of the environment and the health and safety of people.

There were no releases from these sites in 2017 and there were no events that could have harmed people or the environment. Country foods and water around these sites remains safe for consumption.

Uranium mines and mills – Ontario

The following uranium mine and mill sites in Ontario are covered in the 2017 report:

- Deloro – decommissioned historic uranium mine, which is undergoing active remediation

- Madawaska – decomissioned historic uranium mine, which is undergoing active remediation

- Agnew Lake – decommissioned uranium mine

- Bicroft – decommissioned uranium mine

- Dyno – decommissioned uranium mine

- Elliot Lake – decommissioned uranium mines

- Denison and Stanrock – decommissioned uranium mines

All of these Ontario sites were in operating many years ago and have been closed down. Work continues on these sites to protect the environment and the health and safety of people.

There were no releases from these sites in 2017 and there were no events that could have harmed people or the environment. Country foods and water around these sites remain safe for consumption.

The work of the CNSC

For 2017, CNSC staff confirmed that these sites remained safe and did not harm people or the environment by:

- conducting regular onsite inspections of all sites, including measuring radiation levels and releases to the environment

- reviewing information provided by the licensee, confirming that the sites are operated safely

- conducting independent monitoring of food and water at some sites, to demonstrate that the environment and people are protected

- reporting this information to the public

More information can be found in the Regulatory Oversight Report for Uranium Mines, Mills, Historic and Decommissioned Sites in Canada: 2017.

Executive Summary

The Regulatory Oversight Report for Uranium Mines, Mills, and Historic and Decommissioned Sites in Canada: 2017 presents Canadian Nuclear Safety Commission (CNSC) staff’s assessment of licensee performance for operating, historic and decommissioned uranium mines and mills regulated by the CNSC. Information provided covers the 2017 calendar year for operating uranium mines and mills and the 2016 and 2017 calendar years for historic and decommissioned sites. This report also provides an update on staff activities related to public information, community engagement, and relevant aspects of the CNSC’s Independent Environmental Monitoring Program. Where possible, trends are shown and information is compared to previous years.

CNSC staff use the safety and control area framework, which contains 14 safety and control areas (SCAs) to evaluate the performance of each licensee. This report provides performance ratings for all 14 SCAs for operating uranium mines and mills and, where applicable, for historic and decommissioned uranium mines and mills. This report focuses on three SCAs that contain the majority of the key performance indicators for these facilities: radiation protection, environmental protection, and conventional health and safety.

The SCA ratings in this report were derived from results of compliance activities conducted by CNSC staff. These activities included onsite inspections, technical assessments, review of reports submitted by licensees, event and incident reviews, and ongoing exchanges of information with licensees.

For the 2017 reporting year, CNSC staff rated all SCAs “satisfactory” for all operating uranium mines and mills – with the exception of the McClean Lake radiation protection SCA, which was rated “fully satisfactory”.

For the 2016 reporting year, CNSC staff rated all SCAs “satisfactory” for all historic and decommissioned sites – with the exception of the radiation protection SCA for Rayrock, Port Radium and Agnew Lake, which were rated as “below expectations”. CNSC staff determined that while these three sites had specific elements of a radiation protection program (such as dosimetry, signage and limited access) the licensees’ radiation protection programs were not comprehensive or well structured.

For the 2017 reporting year, all SCAs for historic and decommissioned sites were rated “satisfactory” with the exception of the Elliot Lake, which was rated “below expectations” for the environmental protection SCA. Nonetheless, CNSC staff have confirmed that safety to persons and the environment was not compromised at these sites.

CNSC staff confirmed that all operating uranium mine and mill sites in Canada operated safely during 2017, and that historic and decommissioned uranium mine and mill sites operated safely through 2016 and 2017.

CNSC staff also concluded that the licensees for the regulated sites covered in this report have made adequate provision for the health and safety of workers, the protection of the public and the environment, and Canada’s international obligations. Documents referenced in this report are available to the public upon request.

This page was intentionally left blank.

Table of Contents

- 1. Introduction

- Section I - Operating Uranium Mines and Mills

- Section II: Historic and Decommissioned Uranium Mine and Mill Sites

- Appendix A: Facility licensing information

- Appendix B: List of Inspections by Facility and Safety and Control Area

- Appendix C: Safety and Control Area Definitions

- Appendix D: Safety and Control Area Rating Methodology

- Appendix E: Safety and Control Area Ratings

- Appendix F: Financial Guarantees

- Appendix G: Worker Dose Data

- Appendix H: Reportable Releases to the Environment (Spills) and Definitions of CNSC Significance Ratings

- Appendix I: Lost-Time Injuries

- Appendix J: Exceedances of Radiological Action Levels Reported to the CNSC

- Appendix K: Annual Releases of Radionuclides to the Environment

- Appendix L: Additional Information

- Appendix M: Acronyms

- References

1. Introduction

1.1 Background

The Canadian Nuclear Safety Commission (CNSC) regulates Canada’s operating, historic and decommissioned uranium mines and mills to protect health, safety, security and the environment; to implement Canada’s international commitments on the peaceful use of nuclear energy; and to disseminate objective scientific, technical and regulatory information to the public. This mandate is derived from the Nuclear Safety and Control Act (NSCA), which, along with the regulations made under it, contains requirements with which CNSC licensees must comply.

Each year, the CNSC produces a regulatory oversight report on the operating performance of Canada’s uranium mines and mills licensees and licensed facilities. Every second year, this report also provides updates on historic and decommissioned uranium mine and mill sites. This report includes data for the 2017 calendar year for operating uranium mines and mills, and data for the 2016 and 2017 calendar years for historic and decommissioned sites.

The report:

- describes the CNSC’s regulatory efforts, public information and community engagement activities, and Independent Environmental Monitoring Program

- includes information on licensee operations, licence changes and major developments at licensed facilities and sites, as well as any significant events

- presents the performance rating for each safety and control area (SCA) for operating, historic and decommissioned uranium mine and mill facilities regulated by the CNSC

- presents performance data on the SCAs of radiation protection, environmental protection, and conventional health and safety for each licensed facility

This report summarizes CNSC staff’s assessment of the following regulated uranium mine and mill facilities:

-

Operating facilities

- Cigar Lake

- McArthur River

- Rabbit Lake

- Key Lake

- McClean Lake

-

Decommissioned historic sites that are undergoing active remediation

- Gunnar

- Lorado

- Deloro

- Madawaska

-

Decommissioned sites

- Beaverlodge

- Cluff Lake

- Rayrock

- Port Radium

- Agnew Lake

- Bicroft

- Dyno

- Elliot Lake

- Denison and Stanrock

Throughout the review period, the CNSC continued to perform compliance activities – including inspections and reviews of licensee submissions and events –for all operating, historic and decommissioned uranium mine and mill sites.

1.2 CNSC regulatory efforts

1.2.1 Licensing

The CNSC regulates each uranium mine, mill, historic, and decommissioned site under a separate licence. Appendix A presents the licensing information for the operating, historic and decommissioned sites that are discussed in this report.

An approved licence under the NSCA defines licence terms, licensed activities and licence conditions. Where referred to in the licence, an accompanying licence conditions handbook (LCH) contains compliance verification criteria used by CNSC staff to ensure compliance with the conditions comprising the licence. In some cases, LCHs for historic and decommissioned sites were being developed at the time of this report. Any changes made to the LCHs during this review period are provided in appendix A.

Following a public hearing held on June 7 and 8, 2017, the operating licence for McClean Lake was renewed by the Commission. This is discussed in detail in section 7. In 2017, the Deloro and Rayrock licences were both renewed through a designated officer decision. This is discussed in detail in sections 11 and 15, respectively.

1.2.2 Compliance

The CNSC ensures licensee compliance through verification, enforcement and reporting activities. CNSC staff develop compliance plans for each facility, commensurate with the associated risk, and implement these plans by conducting regulatory activities, including onsite inspections and technical assessments of licensee programs, processes and reports. Changes to compliance plans are made on an ongoing basis in response to events, facility modifications and changes in licensee performance.

Tables 1.1 and 1.2 present data on CNSC staff inspections conducted at operating, historic and decommissioned uranium mine and mills in 2017. Enforcement actions arising from these inspections were provided to the licensees in detailed inspection reports and recorded in the CNSC Regulatory Information Bank, in order to ensure these actions were tracked to completion. CNSC staff verified that licensees have complied with the conditions of enforcement actions and that all actions have been closed.

| Year | Inspections | Instances of non-compliance |

|---|---|---|

| 2017 | 30 | 23 |

| Year | Inspections | Instances of non-compliance |

|---|---|---|

| 2016 | 18 | 10 |

| 2017 | 12 | 12 |

All instances of non-compliance that were identified at operating, historic and decommissioned sites were of low safety significance. Additional details on the inspections covered in this reporting period can be found in appendix B. CNSC staff assessed licensees’ corrective actions taken in response to identified instances of non-compliance, and verified that the actions were appropriate and acceptable. All enforcement actions were addressed appropriately by licensees and have been closed by CNSC staff.

Other regulatory bodies that conduct inspections at the operating facilities include the Saskatchewan Ministry of Environment, the Saskatchewan Ministry of Labour Relations and Workplace Safety, the Ontario Ministry of Environment and Climate Change, the Ontario Ministry of Labour, and Environment and Climate Change Canada. These regulatory bodies focus primarily on areas of conventional health and safety and environmental protection. CNSC staff take into account the findings from these regulatory bodies when assessing licensees’ performance. When logistically reasonable, joint inspections are conducted with other federal, provincial or territorial regulatory agencies.

1.2.3 Safety and Control Area Framework

SCAs are the technical topics that CNSC staff use across all regulated facilities and activities to assess, evaluate, review, verify and report on regulatory requirements and performance. The CNSC’s SCA Framework, which staff use to evaluate licensee safety performance, includes 14 SCAs. Each SCA is subdivided into specific areas that define its key components. Appendix C provides definitions of SCAs and their specific areas.

CNSC staff use the following four ratings to grade licensee performance in each applicable SCA

- fully satisfactory (FS)

- satisfactory (SA)

- below expectations (BE)

- unacceptable (UA)

Appendix D provides descriptions of these performance ratings.

This report provides CNSC staff’s performance ratings for all applicable SCAs, with a focus on the three SCAs that cover many of the key performance indicators for these operations: radiation protection, environmental protection, and conventional health and safety.

For 2016, historic and decommissioned sites were rated “satisfactory” in most SCAs. The exception was the radiation protection SCA, which was rated “below expectations” for Rayrock, Port Radium, and Agnew Lake mines. Although this SCA was rated “below expectations” for these three sites, CNSC staff determined that this was of low risk due to the nature of the site activities and existing mitigation measures in place. Additional information is provided in sections 15 to 17 of this report.

For 2017, all historic and decommissioned sites were rated “satisfactory” in most SCAs, with the exception of Elliot Lake, which was rated “below expectations” in environmental protection. Additional information is provided in section 20 of this report.

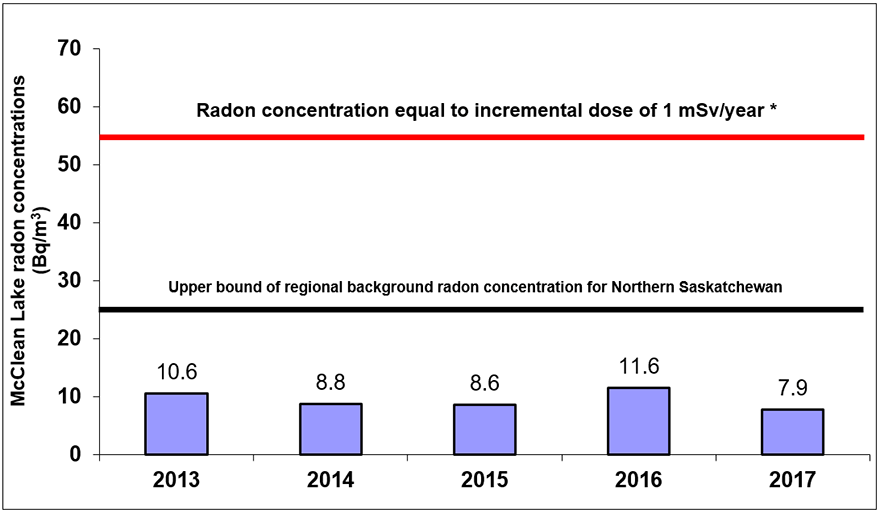

For 2017, all SCA performance ratings for operating uranium mines and mills were rated “satisfactory”, with the exception of radiation protection at McClean Lake which was rated “fully satisfactory”. Additional information related to radiation protection at the McClean Lake Operation is provided in section 7.2 of this report.

CNSC staff concluded, based on the results from regulatory oversight activities, that uranium mine and mill facilities met the following requirements:

-

Radiation protection measures were effective, and radiation doses received by workers remained as low as

reasonably achievable (ALARA):

- no worker doses in excess of regulatory effective dose limits

- no reported exceedances of action levels

-

Environmental protection programs were effective and resulted in emissions and effluents remaining ALARA.

Emissions and effluent management across all uranium mines and mills resulted in:

- one exceedance of the discharge limits outlined in the Metal Mining Effluent Regulations

- no exceedances of provincial limits

-

Conventional health and safety programs continued to protect workers:

- one reported lost-time injury

Appendix E contains the SCA performance ratings from 2013 to 2017 for operating uranium mines and mills, and the SCA performance rating s from 2015 to 2017 for historic and decommissioned sites.

1.2.4 Independent environmental monitoring program

Under the NSCA, the CNSC requires each nuclear facility licensee to develop, implement and maintain an environmental monitoring program to demonstrate that the public and the environment are protected from releases to the environment related to the facility’s nuclear activities. The results of these monitoring programs are submitted to the CNSC to ensure compliance with applicable guidelines and limits, as set out in regulations that govern Canada’s nuclear industry.

The CNSC has implemented an Independent Environmental Monitoring Program (IEMP) to independently verify that all persons and the environment around licensed nuclear facilities are protected. The IEMP is a regulatory tool that complements and informs the CNSC’s ongoing compliance verification program. The IEMP does not rely on licensees to provide samples. CNSC staff or independent contractors obtain samples from publicly accessible areas around the facilities, measuring and analyzing the amount of radiological and hazardous substances in these samples.

As part of the CNSC’s IEMP, samples were collected in three publicly accessible areas around the Cluff Lake site in 2017 and around the Deloro mine site in 2016. Results indicated that the public and the environment around the Cluff Lake site and the Deloro site are protected and there are no health impacts as a result of site operations. These results were consistent with results submitted by the respective licensees demonstrating that their environmental protection programs protect the health and safety of people and the environment. Results from IEMP sampling campaigns are available on the CNSC’s IEMP Web page.

1.3 Public information and community engagement

The CNSC is committed to keeping the public informed of regulatory activities occurring at operating mine and mill facilities. This is in accordance with its mandate to disseminate scientific, technical and regulatory information about its activities, and of the effects, on the environment and on the health and safety of persons, of the development, production, possession, transport and use of nuclear substances.

Ongoing CNSC public engagement efforts include meetings with stakeholders, updates to website information, and an ongoing social media presence. During public engagement activities, the CNSC often staffs a booth to provide important information on its regulatory role and mandate, as well as to answer any questions from community members.

To ensure that licensees provide open and transparent information to the public, the CNSC published new regulatory requirements in RD/GD-99.3, Public Information and Disclosure, in 2013. These requirements were then incorporated into each licence’s LCH. According to RD/GD‑99.3, licensees are required to implement and maintain public information and disclosure programs. These programs are supported by disclosure protocols that outline the type of information to be shared with the public on the operation or site and its activities (e.g., incidents, major changes to operations, periodic environmental performance reports) and how that information will be shared. These requirements ensure effective communication of timely information about the health and safety of persons, the environment and other issues associated with the lifecycle of nuclear facilities. CNSC staff confirmed through regulatory oversight activities that uranium mine and mills licensees implemented public information and disclosure programs in compliance with RD/GD‑99.3, in the reporting period covered by this document.

In 2017, licensees and CNSC staff continued regular communication with interested communities. As part of licensee public information programs and outreach activities, licensees and CNSC staff regularly participate in Northern Saskatchewan Environmental Quality Committee (EQC) meetings and facility tours. Established in 1995, the EQC represents more than 30 communities – many of which are Indigenous – throughout the greater northern Saskatchewan region. The committee enables Northerners to learn more about uranium mining activities and to see first-hand the environmental protection measures being employed in these operations. Regularly scheduled meetings of the Northern Saskatchewan EQC resumed in 2017; CNSC staff participate in EQC meetings when requested. Further information can be found on the EQC Web page.

Indigenous and public engagement

The CNSC is committed to ongoing engagement and relationship building with interested Indigenous communities. First Nations and Métis communities with interest in Canada’s uranium mines and mills were provided a copy of this regulatory oversight report. Through the CNSC’s Participant Funding Program (PFP), financial support was made available for participation in the review of this report. Last year, participant funding was awarded to five recipients for the review of the Regulatory Oversight Report for Uranium Mines and Mills in Canada: 2016 (Yá’thi Néné Land and Resource Office; Buffalo River Dene Nation; Birch Narrows Dene Nation; Sydon Consulting; and Saskatchewan Environmental Society). In addition, CNSC staff provided interested Indigenous communities with updates on IEMP sampling campaigns at uranium mine, mill, historic and decommissioned sites.

To ensure that licensees engage with Indigenous communities, the CNSC published REGDOC‑3.2.2, Aboriginal Engagement in 2016. REGDOC-3.2.2 sets out requirements and guidance for licensees proposing projects that may raise the Crown’s duty to consult. Throughout this reporting period, licensees continued to host meetings and to discuss their operations with Indigenous communities, and CNSC staff participated in many of these meetings.

Activities attended and carried out by CNSC staff in 2017 included the following:

- April 25, 2017 – Saskatchewan Mining Association Exhibition and Information session: The meeting was attended by approximately 300 students and community members from La Loche and surrounding areas.

- June 22, 2017 – Northern Mine Monitoring Secretariat update to the EQC: The meeting included EQC members, and various Government of Saskatchewan representatives.

- September 25–26, 2017 – Mining for Society: This two-day event, aimed at students in the Saskatoon area, showcased the mining industry. It was attended by approximately 700 students.

- October 17, 2017 – Fedoruk Center “coffee break” information session: This was a public event where CNSC staffed a presentation booth and answered questions.

- November 6, 2017 – Meeting with Ya’thi Néné Land and Resource Office regarding PFP funding for the 2016 regulatory oversight report and information session. The meeting included representatives from the Athabasca Dene First Nations, CNSC, Cameco and AREVA. There were approximately 40 people in attendance.

- November 7, 2017 РCommunication with Pinehouse, Kineepik M̩tis Local Inc., to answer questions regarding contaminated waste management at Key Lake.

A licence renewal hearing was held for the McClean Lake Operation in June 2017 in La Ronge, Saskatchewan. As part of this licence renewal, CNSC staff undertook focused engagement activities and actions. Per the CNSC’s public notification process for Commission proceedings, CNSC staff informed the public of the Commission hearing and availability of the PFP through the CNSC’s website, email subscription list, social media channels, and radio and print advertisements in local northern Saskatchewan communities. Participant funding was awarded to Birch Narrows Dene Nation and Buffalo River Dene Nation for a meeting with CNSC staff on May 25, 2017, to discuss the McClean Lake Operation licence renewal. CNSC staff remain committed to working with the many communities to better understand their interests and concerns.

The northern communities are heavily engaged in the activities associated with mine and mill operations as employees, suppliers and participants in numerous agreements. A report produced by the province of Saskatchewan, titled Benefits from Northern Mining, 2017 Summary, provides an overview of the benefits associated with mining in northern Saskatchewan. As of December 31, 2017, the northern mines employed over 2,400 people in direct and contract jobs. The mines maintain a high northern participation rate, with 48% of mine employees classified as Northerners. Northern mines are one of the largest employers of Indigenous peoples in Canada.

1.4 Decision on radionuclide reporting in National Pollutant Release Inventory

In response to a public request to add radionuclides to the National Pollutant Release Inventory (NPRI) substance list, this information has been made available and is provided in appendix K: Annual Releases of Radionuclides to the Environment.

The CNSC is making this data accessible as part of its mandate to disseminate this information to the public, and in demonstration of its commitment to open government. The original request to add radionuclides to the NPRI, the Government of Canada response, and the subsequent request from environmental non-governmental organizations are available upon request by contacting the NPRI program.

Section I – Operating Uranium Mines and Mills

2. Overview

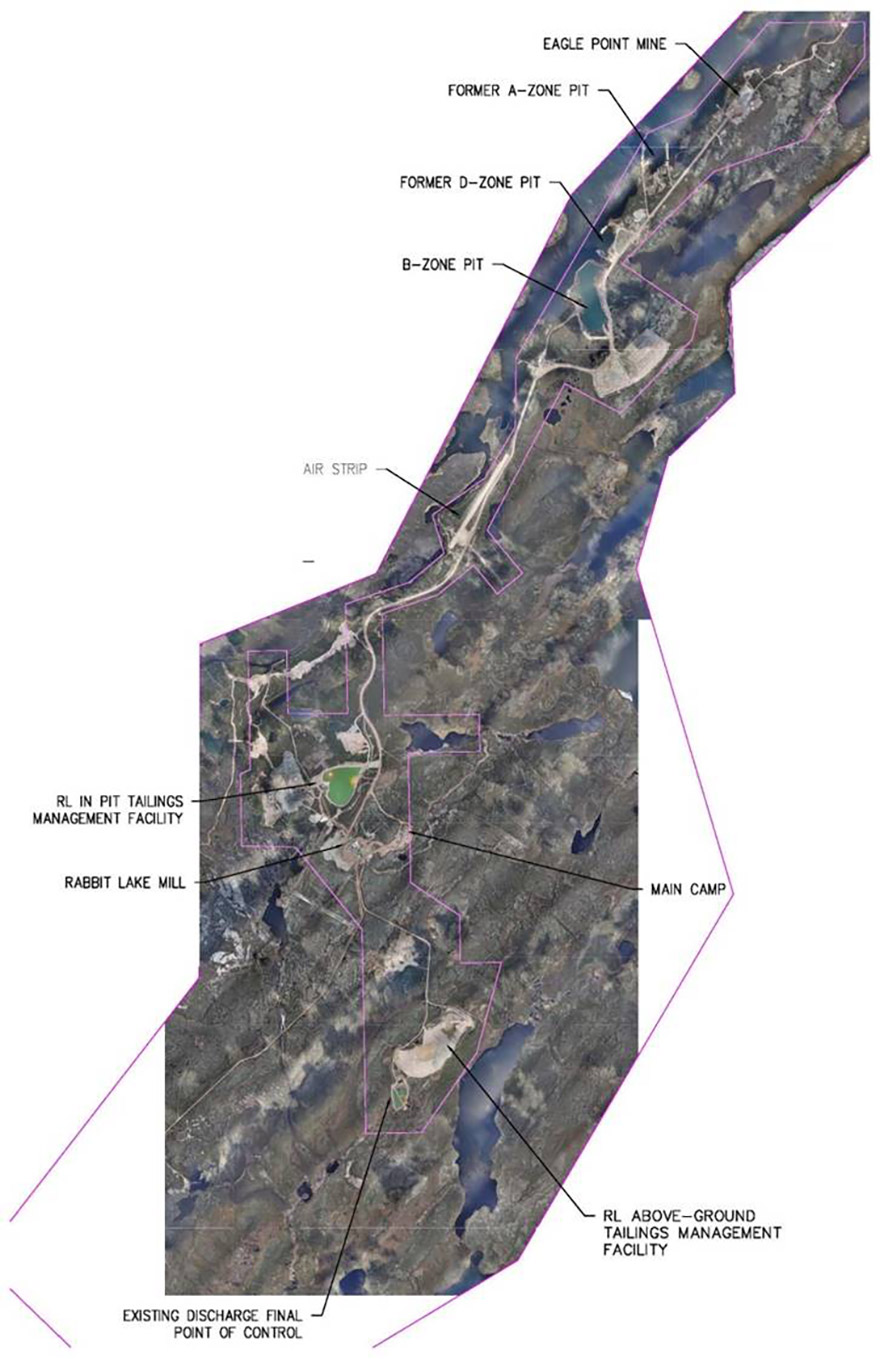

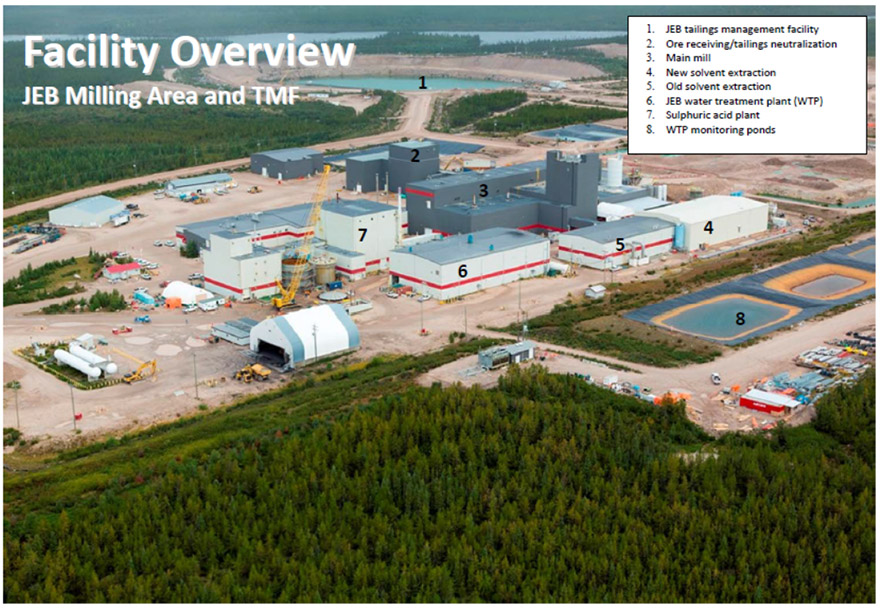

This section of the report focuses on the performance of the five uranium mines and mills operating in Canada in 2017. The facilities listed are located within the Athabasca Basin of northern Saskatchewan and are shown in figure 2.1:

- Cigar Lake Operation

- McArthur River Operation

- Rabbit Lake Operation

- Key Lake Operation

- McClean Lake Operation

.png/object)

The 2017 uranium production data for these operating mine and mill facilities are shown in table 2.1. CNSC staff confirmed that all facilities operated within their authorized annual production limits in 2017.

| Production data1 | Cigar Lake | McArthur River | Rabbit Lake2 | Key Lake3 | McClean Lake4 |

|---|---|---|---|---|---|

| Mining – ore tonnage (Mkg/year) | 36.49 | 91.44 | 0 | N/A5 | 0 |

| Mining – average ore grade mined (%U) | 18.85% | 7.09% | 0% | N/A | 0% |

| Mining – U mined (Mkg U/year) | 6.88 | 5.88 | 0 | N/A | 0 |

| Milling – mill ore feed (Mkg/year) | N/A | N/A | 0 | 143.26 | 36.35 |

| Milling – average mill feed grade (%U) | N/A | N/A | 0% | 4.32% | 19.30% |

| Milling – mill recovery (%U) | N/A | N/A | 0% | 99.05% | 99.03% |

| Milling – U concentrate produced (Mkg U/year) | N/A | N/A | 0 | 6.20 | 6.93 |

| Authorized annual production (Mkg U/year) | 9.25 | 9.6 | 4.25 | 9.6 | 9.23 |

|

1 1 Mkg = 1,000,000 kg. 2 Rabbit Lake was in a state of safe care and maintenance during this reported period. 3 At Key Lake, McArthur River ore is blended with stockpiled lower-grade material to produce a lower-grade mill feed. 4 The McClean Lake mill has been designed to mill high-grade ore from Cigar Lake without any blending or dilution. 5 N/A = not applicable. |

|||||

Licensees are required to develop preliminary decommissioning plans and associated financial guarantees to ensure that work activities are covered financially and work is guaranteed for completion with no liability to the government. Financial guarantee values for the operating mine and mill facilities range from approximately C$48 million at the McArthur River Operation to C$218 million at the Key Lake Operation. The values of the financial guarantees are listed in appendix F. Financial guarantees cover all costs necessary to fully decommission and remediate a uranium mine and/or mill to ensure the protection of people and the environment.

2.1 Regulatory efforts

The CNSC regulates the five uranium mine and mill operations under separate licences. Appendix A provides an outline of these licences and their respective licensing information. CNSC staff verified licensee compliance with regulatory requirements through activities such as inspections, reviews and assessments of reports and licensee programs. These compliance verification activities were supplemented with meetings, presentations and facility visits.

In 2017, CNSC staff performed six inspections at each uranium mine and mill operation for a total of 30 onsite inspections (these are outlined in appendix B). These inspections resulted in the identification of 23 instances of non-compliance, all of low safety significance. CNSC staff assessed all licensee corrective actions taken in response to non-compliance, and verified that these actions were appropriate and acceptable. All corrective actions implemented by licensees are considered closed.

2.2 Performance

The CNSC’s safety and control area (SCA) performance ratings for operations were developed using professional judgment and expertise. Ratings are based on the review of key performance indicators (e.g., accident/event occurrences, responses to accidents/events, desktop review of reports, dose information, and both radiological and non-radiological environmental results) and the results of compliance activities, such as inspections and technical assessments.

Once established, ratings are compared across all five operating mines and mills and to the rating methodology defined in appendix D to ensure that consistent and defendable ratings are assigned. For 2017, CNSC staff assigned performance ratings of either “satisfactory” or “fully satisfactory” to operating uranium mines and mills. Table 2.2 presents the SCA ratings for each operating facility for 2017, and appendix E contains the SCA ratings for each facility (operating, historic and decommissioned) from 2013 to 2017.

| Safety and control area | Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake |

|---|---|---|---|---|---|

| Management system | SA | SA | SA | SA | SA |

| Human performance management | SA | SA | SA | SA | SA |

| Operating performance | SA | SA | SA | SA | SA |

| Safety analysis | SA | SA | SA | SA | SA |

| Physical design | SA | SA | SA | SA | SA |

| Fitness for service | SA | SA | SA | SA | SA |

| Radiation protection | SA | SA | SA | SA | FS |

| Conventional health and safety | SA | SA | SA | SA | SA |

| Environmental protection | SA | SA | SA | SA | SA |

| Emergency management and fire protection | SA | SA | SA | SA | SA |

| Waste management | SA | SA | SA | SA | SA |

| Security | SA | SA | SA | SA | SA |

| Safeguards and non‑proliferation | SA | SA | SA | SA | SA |

| Packaging and transport | SA | SA | SA | SA | SA |

|

FS = fully satisfactory SA = satisfactory |

|||||

This report focuses on the three SCAs that cover many of the key performance indicators for these facilities: radiation protection, environmental protection and conventional health and safety.

Licensees develop and maintain management systems that include integrated links to all 14 SCAs. Management systems are the framework that establish the processes and programs required to ensure an organization achieves its safety objectives, continuously monitors performance, identifies inadequacies, and continually improves and fosters a healthy safety culture. CNSC staff reviewed and assessed program performance and key performance indicators across radiation protection, environmental protection, and conventional health and safety management systems through regular compliance verification activities throughout 2017.

2.3 Radiation protection

Uranium mine and mill licensees in Canada are required to implement and maintain radiation protection programs. Each program must ensure that contamination levels and radiation doses received by individuals are monitored, controlled and maintained below regulatory limits and as low as reasonably achievable (ALARA).

For 2017, CNSC staff rated the radiation protection SCA at all five operating facilities as “satisfactory” or “fully satisfactory”, based on regulatory oversight activities.

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake |

|---|---|---|---|---|

| SA | SA | SA | SA | FS |

|

FS = fully satisfactory SA = satisfactory |

||||

Radiological hazard control

Sources of radiation exposure at uranium mines and mills include:

- gamma radiation

- long-lived radioactive dust

- radon progeny

- radon gas

CNSC staff’s compliance activities confirmed that these hazards were controlled by licensees’ radiation protection programs, including practices related to the effective use of time, distance and shielding; source control; ventilation; contamination control; and personal protective equipment.

Radiation protection program performance

During 2017, CNSC staff conducted regulatory oversight activities in the radiation protection SCA at all five operating facilities. These activities were to verify that licensees were complying with regulatory requirements for implementation of radiation protection programs.

Radiation protection programs include codes of practice that outline licensee administrative levels and action levels for exposures and doses of radiation. Administrative levels include a list of specific actions to be taken by the licensee based on radiological monitoring in the workplace. The radiation protection programs include actions to be taken under specific conditions; for example:

- “continue to work while monitoring or investigating a parameter”

- “leave the area and initiate an investigation”

As radiation levels or worker exposure levels increase, the required protective actions become more stringent.

Administrative levels are identified for all radiological hazard types, apply to normal operating conditions, and are used to ensure optimal conditions for workers. Licensees are responsible for identifying the parameters of their programs that represent timely indicators of potential losses of control. For this reason, action and administrative levels are licensee-specific and may change over time depending on operational and radiological conditions. If an action level is reached, it may indicate a loss of control of part of a licensee’s radiation protection program. The licensee is then required to establish the cause, notify the CNSC, and, if applicable, restore the effectiveness of the radiation protection program.

The five operating uranium mines and mills have the same individual radiation dose action level of 1 millisievert (mSv) per week and 5 mSv per quarter of a given year. No radiation-related action levels were reported by the operating mines and mills in 2017.

Figure 2.2 shows a CNSC inspector taking a gamma dose rate measurement at the McArthur River water treatment holding pond.

CNSC staff confirmed that, during the reporting period, the radiation protection programs and practices at operating mines and mills remained effective in controlling radiological exposure to workers. No action levels were reached in 2017.

Application of ALARA

The radiation protection programs established by uranium mine and mill licensees include responsibilities and processes for ensuring that exposures to workers are maintained ALARA.

Through scheduled compliance oversight activities, CNSC staff verified that key elements of these ALARA programs (e.g., management control over work practices, personnel qualification and training, control of occupational and public exposure to radiation, and planning for unusual situations) were effectively implemented by uranium mine and mill licensees in 2017.

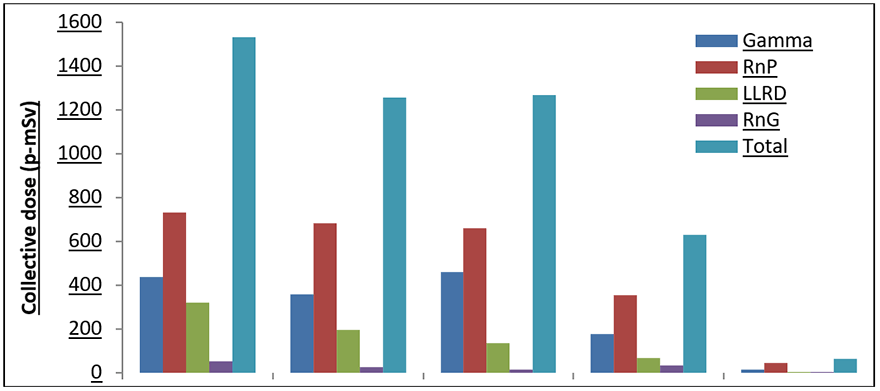

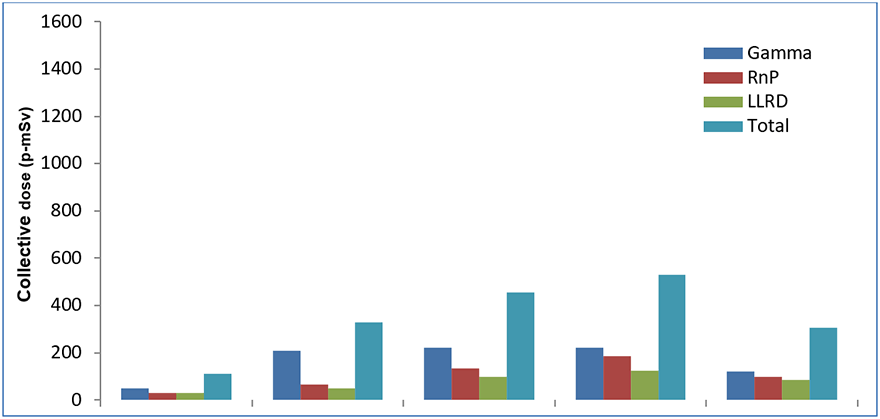

This report includes the reporting of annual collective dose values for nuclear energy workers (NEWs), for each operating mine and mill (see sections 3.2, 4.2, 5.2, 6.2 and 7.2). The collective dose value is the sum of the effective doses received by all NEWs at a uranium mine and mill in one year. Collective dose is a radiation protection performance indicator that provides the total exposures associated with each operation. It supplements other performance statistics, like average dose, which have been affected by factors including changes in the number of workers or workers who receive radiation exposures over very short periods of time. Collective dose shows the effect of increased or reduced site activities; for example, the transition of the Rabbit Lake Operation from active mining and milling of ore to a “care and maintenance” status (see figure 5.3), or the ramping up of production at the McClean Lake Operation (see figure 7.3).

Worker dose control

In accordance with the Radiation Protection Regulations, licensee radiation protection programs include processes and criteria to provide assurance that all individuals identified as NEWs, in accordance with section 2 of the NSCA, are appropriately designated and trained. This includes licensee employees and contractors. Radiation exposures are ascertained through approved dosimetry methods, and workers are notified of the results.

At all operating uranium mines and mills, NEWs are issued optically stimulated luminescence dosimeters that measure external gamma radiation exposure and resulting doses. Where required, workers also wear personal alpha dosimeters (PADs) to measure alpha radiation exposure from radon progeny and radioactive dust. Optically stimulated luminescence dosimeters and PAD readings are measured by a CNSC-licensed dosimetry service provider. Where direct monitoring through dosimeters is not warranted, approved dose estimation methods (such as area/group monitoring and time cards) are used in accordance with CNSC regulatory guidance. CNSC staff confirmed that all licensees for the operating facilities discussed in this report met regulatory requirements for the use of licensed dosimetry, during the reporting period.

Figures 2.3 and 2.4 show the average individual effective doses and maximum individual effective doses during the 2013 to 2017 reporting period for the five operating facilities. In 2017, no worker at any facility exceeded the regulatory individual effective dose limit of 50 mSv in one year and 100 mSv in a five-year dosimetry period.

.png/object)

Figure 2.3 - Text version

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake | |

|---|---|---|---|---|---|

| 2013 | 0.27 | 0.89 | 1.30 | 0.62 | 0.36 |

| 2014 | 0.16 | 1.03 | 1.35 | 0.63 | 0.37 |

| 2015 | 0.45 | 1.00 | 1.36 | 0.55 | 0.89 |

| 2016 | 0.39 | 0.85 | 0.85 | 0.62 | 1.04 |

| 2017 | 0.34 | 0.79 | 0.40 | 0.66 | 0.91 |

|

* The annual regulatory limit illustrated applies to individual effective dose and is shown for reference only. |

|||||

Increases and decreases over time in effective dose to NEWs are explained in facility-specific sections of this report (sections 3.2, 4.2, 5.2, 6.2 and 7.2) under “worker dose control”.

.png/object)

Figure 2.4 - Text version

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake | |

|---|---|---|---|---|---|

| 2013 | 2.21 | 7.58 | 11.67 | 5.67 | 3.44 |

| 2014 | 2.04 | 7.91 | 8.84 | 6.21 | 2.03 |

| 2015 | 5.99 | 7.40 | 9.14 | 7.56 | 5.28 |

| 2016 | 5.53 | 7.02 | 4.95 | 5.37 | 6.94 |

| 2017 | 3.36 | 5.73 | 1.56 | 5.39 | 5.12 |

The highest maximum individual effective dose to a worker at an operating uranium mine and mill in 2017 occurred at the McArthur River facility. A dose of 5.73 mSv was assigned to an underground process worker who regularly worked in the semi-autogenous grinding mill area. This value is 11.5% of the annual dose limit of 50 mSv.

Appendix G shows the number of NEWs at each operating facility, with corresponding average individual effective doses and maximum individual effective doses, for the 2013 to 2017 period.

Estimated dose to the public

Uranium mine and mill operations are remote from local populations. The Radiation Protection Regulations set a public radiation dose limit of 1 mSv per year above natural background radiation, to ensure protection of the health of the public. Radiological exposures measured at the boundaries of these remote licensed facilities are close to background radiation levels. As published in the CNSC fact sheet on natural background radiation, the background radiation level for Canada is approximately 1.8 mSv.

In 2017, CNSC staff were satisfied that uranium mine and mill licensees controlled radiation doses to persons at levels well below regulatory limits, and that licensees kept doses ALARA.

This conclusion was based on the outcome of inspections, as well as reviews of licensees’ radiation protection programs, radiological hazard control, worker dose control and application of the ALARA principle.

2.4 Environmental protection

The environmental protection SCA covers programs that identify, control and monitor releases of radioactive and hazardous substances and effects on the environment from facilities as a result of licensed activities.

Based on regulatory oversight activities, CNSC staff rated the 2017 performance of all five operating uranium mine and mill facilities for the environmental protection SCA as “satisfactory”. CNSC staff concluded that licensees’ environmental protection programs were effectively implemented and met all regulatory requirements.

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake |

|---|---|---|---|---|

| SA | SA | SA | SA | SA |

| SA = satisfactory | ||||

Environmental management system

The CNSC requires licensees to develop and maintain environmental management systems that provide a framework for integrated activities related to environmental protection at their operations. Environmental management systems are described in approved environmental management programs and include activities such as establishing annual environmental objectives, goals and targets. Licensees conduct internal audits of their programs as identified in their CNSC-approved management system program. Through regular compliance verification activities, CNSC staff confirmed that licensees’ objectives, goals and targets were met in 2017. Site-specific details are provided in sections 3.3, 4.3, 5.3, 6.3 and 7.3 of this report.

Environmental risk assessment

The CNSC uses site-specific, licensee-developed environmental risk assessments (ERAs) as a regulatory tool throughout the lifecycle of uranium mine and mill facilities. Applicants use ERAs during initial environmental assessments for new facilities and for changes to existing facilities or activities at licensed operations, where applicable. The ERA identifies the need for mitigation technologies or practices, and it predicts:

- physical disturbances

- releases to the atmosphere

- changes to surface water quality

- changes to groundwater quality

- changes to the physical environment

- any biological effects

Operating uranium mines and mills are required to submit updated ERAs to the CNSC every five years. ERAs are typically updated based on operational activities, revised predictions, historic monitoring information and the latest science. CNSC staff regularly review ERAs to determine potential risks to human health and the environment and to verify that mitigation measures are adequate.

Assessment and monitoring

In accordance with the Uranium Mines and Mills Regulations, each uranium mine and mill licensee has an environmental monitoring program that monitors releases of nuclear and hazardous substances, and to characterize any effects to the environment associated with the licensed facility. Nuclear and hazardous substances associated with monitoring programs are selected based on regulated contaminants and constituents of potential concern (COPC) identified through the licensee’s ERA. COPC identified through the ERA with the potential for adverse environmental effects are managed through increased monitoring, inclusion in the environmental code of practice, and further study or implementation of additional controls by the licensee. CNSC staff periodically review environmental monitoring programs as criteria for assessing environmental performance.

Environmental monitoring programs are associated with an environmental code of practice that sets out administrative levels and action levels for select COPC with the potential for adverse environmental effects. An administrative level represents the upper range of design specifications for a specific parameter. Reaching an administrative level triggers an internal review by the licensee. Exceedance of an action level indicates a potential loss of control of the environmental protection program, which is based on the approved facility design envelope, and triggers actions that must be taken by the licensee to correct the problem. This requires notification to the CNSC, an immediate investigation, subsequent corrective actions and preventive measures, in order to restore the effectiveness of the environmental protection program. It is important to recognize that an exceedance of an action level does not imply a potential risk to the environment, but identifies that the operating parameter may be outside the facility design envelope. Facility administrative and action levels are determined through the identification and proper operation of existing treatment technologies, as well as facility-specific environmental risk studies.

In 2017, there were no action level exceedances for treated effluent released to the environment.

CNSC staff have reviewed environmental risk assessments and environmental monitoring results of operating uranium mine and mill facilities and have concluded that the environment was protected during the reporting period.

Uncontrolled releases

For any unauthorized releases (spills) of hazardous or radioactive substances to the environment, licensees are required to report to regulatory authorities, including the CNSC,

Figure 2.5 depicts the number of environmental reportable spills for uranium mine and mill facilities during the 2013 to 2017 reporting period. In each case, CNSC staff reviewed the licensee’s actions to ensure effective remediation and prevention, and they were satisfied with actions taken by the licensee. CNSC staff rated all 2017 spills as “low significance” resulting in no residual impact to the environment.

The site-specific sections and appendix H of this report describe each reportable spill and any corrective actions taken by the licensee in response. The CNSC spill rating definitions are also found in appendix H.

.png/object)

Figure 2.5 - Text version

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake | |

|---|---|---|---|---|---|

| 2013 | 2 | 2 | 3 | 3 | 4 |

| 2014 | 3 | 1 | 4 | 1 | 2 |

| 2015 | 10 | 0 | 2 | 1 | 6 |

| 2016 | 5 | 1 | 2 | 1 | 8 |

| 2017 | 5 | 2 | 1 | 3 | 3 |

Protection of the public

According to regulatory requirements, each licensee must demonstrate that the public is protected from exposures to radiological and hazardous substances released from an operation. Protection of the public is assessed in the ERA, which contains a human health risk assessment (HHRA). The HHRA assesses hazardous and radiological releases from operating facilities, and it models resultant concentrations of contaminants in air, water, soil and traditional foods, such as fish, waterfowl and moose. The concentrations of contaminants consumed by a typical local resident are assessed against human health benchmarks in the HHRA. For all operating facilities, the HHRAs confirmed that concentrations of contaminants for a typical local resident were well below concentrations that could cause health effects, in 2017. It was therefore determined that the health of the public in areas surrounding the operating facilities was protected.

Eastern Athabasca Regional Monitoring Program

The Eastern Athabasca Regional Monitoring Program (EARMP) is a well-recognized environmental monitoring program designed to gather data on long-range environmental information and potential cumulative impacts downstream of uranium mining and milling operations. The program, which was established by the province of Saskatchewan in 2011, monitors the safety of traditionally harvested country foods through analysis of water, fish, berries and wild meat, (e.g., grouse, rabbit, caribou and moose) from representative northern Saskatchewan communities. The program contractor is a northern Saskatchewan Indigenous‑owned business. The program involves the collection of samples from areas identified by community members, who either assist with sample collection or provide samples from their own harvesting activities.

Harvesting and consuming traditional country foods is an important part of the culture in northern Saskatchewan. The intent of the EARMP is to provide confidence and to communicate transparently to community members that traditional country foods remain safe to eat, both today and in future generations. The program has demonstrated that concentrations of chemicals of interest have been relatively consistent over time and generally within the regional reference range, indicating little evidence of long-range transport of contaminants associated with uranium mining.

Evaluation of country food data from previous years confirms that operating uranium mines and mills are not affecting the safety of country foods in nearby communities. The results indicated that radiological and non-radiological exposures of residents consuming country foods were similar to exposures of the general Canadian population, and were also below values considered to be protective of health effects. The EARMP has proven to be a productive means of involving community members in monitoring the health of their local environment, and it has provided them with confidence in the safety of their traditional foods. The conclusion of the EARMP is that water and country foods are considered safe for consumption.

The complete report and data are available on the EARMP website.

CNSC staff continue to support the EARMP and are working to further collaborate on opportunities for this valuable program.

Effluent and emissions control

Treated effluent released to the environment

Licensee-developed ERAs had previously identified releases of molybdenum, selenium and uranium as COPC with potential for adverse environmental effects, across multiple operating uranium mines and mills. As a result, improved engineering controls and treatment technologies to reduce effluent releases of these contaminants were implemented where required. In 2017, the implemented treatment technologies continued to keep these contaminant concentrations stable, below regulatory limits and ALARA. Figures 2.6 to 2.8 display the average annual effluent concentrations for molybdenum, selenium and uranium at the five operating mines and mills, from 2013 to 2017.

In the absence of federal or provincial limits for molybdenum, the CNSC required licensees to develop facility-specific effluent controls within their environmental protection program codes of practice. From 2013 to 2017, average effluent concentrations of molybdenum at the five operating uranium mines and mills were below the action level in the Key Lake code of practice. (Of the five operations, Key Lake has the most stringent action level for molybdenum. This action level is shown for reference only.)

.png/object)

Figure 2.6 - Text version

| Cigar Lake (mg/L) | McArthur River (mg/L) | Rabbit Lake (mg/L) | Key Lake (mg/L) | McClean Lake (mg/L) | |

|---|---|---|---|---|---|

| 2013 | 0.0169 | 0.1878 | 0.3240 | 0.1500 | 0.0052 |

| 2014 | 0.0303 | 0.1865 | 0.2820 | 0.1600 | 0.0024 |

| 2015 | 0.1662 | 0.1458 | 0.2680 | 0.1000 | 0.0024 |

| 2016 | 0.0369 | 0.1851 | 0.2730 | 0.0800 | 0.0020 |

| 2017 | 0.0640 | 0.1460 | 0.1390 | 0.1200 | 0.0040 |

| *Of the five operations, Key Lake has the most stringent action level for molybdenum. This action level is shown for reference only. | |||||

Figures 2.7 and 2.8 demonstrate that both selenium and uranium concentrations in treated effluent released to the environment, from operating mine and mill facilities from 2013 to 2017, remained below Saskatchewan’s licensed effluent discharge limits of 0.6 mg/L and 2.5 mg/L for selenium and uranium, respectively. As indicated on figure 2.8, the CNSC identified an interim objective for uranium of 0.1 mg/L. This was derived based on treatment technologies in place at the uranium mines and mills and based on what would be achievable by the uranium metal mining sector. The interim objective was applied to all uranium mine and mill facilities since it was the most stringent and it has been consistently met. This interim objective for uranium in effluent is in place until the CNSC requirements for release limits are published in REGDOC-2.9.2, which was in development at the time of this report’s publication.

.png/object)

Figure 2.7 - Text version

| Cigar Lake (mg/L) | McArthur River (mg/L) | Rabbit Lake (mg/L) | Key Lake (mg/L) | McClean Lake (mg/L) | |

|---|---|---|---|---|---|

| 2013 | 0.0005 | 0.0014 | 0.0052 | 0.0170 | 0.0004 |

| 2014 | 0.0009 | 0.0024 | 0.0042 | 0.0180 | 0.0007 |

| 2015 | 0.0038 | 0.0025 | 0.0042 | 0.0180 | 0.0092 |

| 2016 | 0.0062 | 0.0037 | 0.0035 | 0.0170 | 0.0210 |

| 2017 | 0.0042 | 0.0036 | 0.0024 | 0.0150 | 0.0110 |

.png/object)

Figure 2.8 - Text version

| Cigar Lake (mg/L) | McArthur River (mg/L) | Rabbit Lake (mg/L) | Key Lake (mg/L) | McClean Lake (mg/L) | |

|---|---|---|---|---|---|

| 2013 | 0.0011 | 0.0107 | 0.0630 | 0.0080 | 0.0015 |

| 2014 | 0.0193 | 0.0095 | 0.0460 | 0.0060 | 0.0018 |

| 2015 | 0.1310 | 0.0089 | 0.0520 | 0.0080 | 0.0042 |

| 2016 | 0.0063 | 0.0055 | 0.0730 | 0.0060 | 0.004 |

| 2017 | 0.0018 | 0.0056 | 0.0700 | 0.0110 | 0.004 |

| *Action level for Rabbit Lake shown (7-day mean of daily composites). | |||||

In addition to the preceding figures that show COPC with the potential for adverse environmental effects, the graph in figure 9 displays radium concentrations. The 2013 to 2017 annual average effluent concentrations of radium-226, for the five operating mines and mills, were well below the CNSC’s licence-authorized effluent discharge limit of 0.37 Bq/L.

.png/object)

Figure 2.9 - Text version

| Cigar Lake (Bq/L) | McArthur River (Bq/L) | Rabbit Lake (Bq/L) | Key Lake (Bq/L) | McClean Lake (Bq/L) | |

|---|---|---|---|---|---|

| 2013 | 0.007 | 0.052 | 0.008 | 0.050 | 0.006 |

| 2014 | 0.008 | 0.058 | 0.010 | 0.050 | 0.007 |

| 2015 | 0.010 | 0.065 | 0.007 | 0.070 | 0.006 |

| 2016 | 0.007 | 0.082 | 0.007 | 0.050 | 0.006 |

| 2017 | 0.007 | 0.061 | 0.007 | 0.070 | 0.006 |

Uranium mine and mill facilities also analyze treated effluent for concentrations of other regulated contaminants and COPC, such as arsenic, copper, lead, nickel, zinc, total suspended solids (TSS), as well as pH levels. Table 2.3 displays the annual average parameter concentration values in effluent for these substances released in 2017, as well as the discharge limits described in the Metal Mining Effluent Regulations (MMER). All metal mines and mills in Canada are subject to MMER, which are made under the federal Fisheries Act. CNSC uranium mine and mill licences incorporate the effluent limit requirements of the MMER. In 2017, all treated effluent released to the environment from the five operating mines and mills – for the preceding substances including pH – did not exceed the effluent discharge limits.

| Parameters | MMER discharge limit | Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake |

|---|---|---|---|---|---|---|

| Arsenic (mg/L) | 0.5 | 0.0750 | 0.0012 | 0.0010 | 0.0080 | 0.0260 |

| Copper (mg/L) | 0.3 | 0.0006 | 0.0010 | 0.0002 | 0.0230 | 0.0030 |

| Lead (mg/L) | 0.2 | 0.0001 | 0.0009 | 0.0001 | 0.0100 | 0.0020 |

| Nickel (mg/L) | 0.5 | 0.0008 | 0.0037 | 0.0017 | 0.1670 | 0.0150 |

| Zinc (mg/L) | 0.5 | 0.0259 | 0.0014 | 0.0006 | 0.0090 | 0.0030 |

| Molybdenum (mg/L) | N/A | 0.0640 | 0.1460 | 0.1390 | 0.1200 | 0.0040 |

| Selenium (mg/L) | N/A | 0.0042 | 0.0036 | 0.0024 | 0.0150 | 0.0110 |

| TSS (mg/L) | 15 | 1 | 1 | 1 | 3 | 2 |

| pH range | 6.0–9.5 | 7.3 | 7.4 | 7.3 | 6.5 | 7.2 |

In 2017, average parameter concentration values in treated effluent released to the environment, from the licensed mining and milling activities at the five operating mines and mills, did not exceed the effluent discharge limits stipulated in CNSC operating licence documentation.

CNSC staff will continue to review effluent quality results to ensure that effluent treatment performance remains effective.

Air emissions released to the environment

Environmental programs at uranium mines and mills include monitoring the effects of operations on the surrounding air and soil. Licensees measure airborne particulate levels and concentrations of regulated contaminants and COPC, as well as the concentration of radon gas in ambient air. Soil and vegetation may be affected by atmospheric deposition of particulate containing adsorbed metals and radionuclides associated with onsite activities. Licensees monitor contaminant concentrations in soil and terrestrial vegetation to verify that operational impacts are ALARA and below regulatory limits.

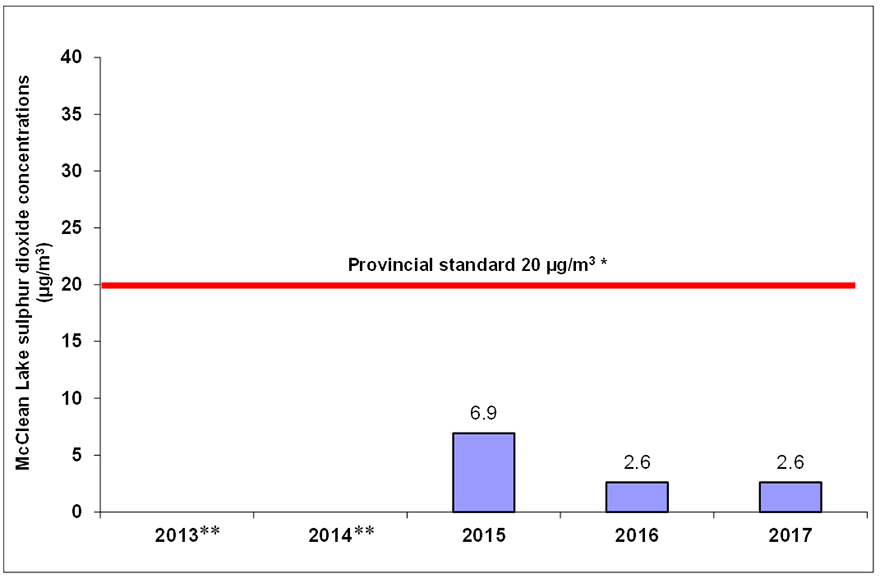

Facilities with milling operations monitor atmospheric emissions from acid plants, yellowcake dryers, calciner operations, packaging, grinding and ammonium sulphate operations. Other measured parameters (e.g., ambient radon and stack testing for sulphur dioxide, uranium and heavy metals) verify facility design and evaluate the operation’s performance against predictions made in ERAs.

CNSC staff verified that the operating mines and mills demonstrated satisfactory performance in mitigating and monitoring the effects of their operations on the surrounding air and soil, during 2017. Some air and soil samples taken from around the facilities indicated emission levels that were slightly above background concentrations in the immediate vicinity of activities; however, concentrations decreased to background levels within a short distance (less than 2 km from the site boundary). The monitoring results indicated negligible impacts to the environment from atmospheric releases, and confirmed that all operating uranium mines and mills complied with their programs and provincial standards, in 2017.

Treated mining/milling effluent: A comparison of the uranium mining sector to other metal mining sectors across Canada

As noted previously in this report, metal mines and mills in Canada are subject to the MMER of the federal Fisheries Act. The quality of effluent treatment by the uranium mining sector compares favourably to that of other metal mining sectors (base metal, precious metal and iron) across Canada.

The data used for analysis and comparison are acquired from Environment and Climate Change Canada. MMER data from 2016 are used for comparison within this report since they comprise the most current sector-specific MMER information available, with the exception of molybdenum, selenium and uranium, for which 2017 data are available. The mines reporting under the MMER and that released treated effluent are grouped into four metal mining sectors based on the primary metal produced. The metal mining sectors are:

- uranium – 5 facilities

- base metals (such as copper, nickel, molybdenum or zinc) – 47 facilities

- precious metals (such as gold or silver) – 54 facilities

- iron – 8 facilities

Molybdenum is a parameter requiring routine monitoring of treated effluent subject to the MMER. Ecological risk assessments completed in the mid-2000s indicated that releases of molybdenum posed a risk to biota, and that this risk merited adaptive management. As a result of a request from Commission members, CNSC licensees of uranium mines and mills incorporated administrative and treatment technology upgrades in their effluent management systems. The success of these actions is evident in figure 2.10, which shows a substantial decrease in molybdenum releases in the uranium mining sector.

In 2017, molybdenum concentrations in uranium mining sector effluent were similar to those measured in effluent of precious metal and iron mines, and less than those measured in effluent of base metal mines.

.png/object)

In mid-2012, a requirement for monitoring selenium was added to the MMER. Table 2.4 summarizes the average selenium concentration in treated effluent from each mining sector using data collected since 2012. Selenium concentration in uranium sector effluent was similar to that of other metal mining sectors in Canada.

| Year | Metal mining sector | |||

|---|---|---|---|---|

| Uranium (mg/L) | Base metals (mg/L) | Precious metals (mg/L) | Iron (mg/L) | |

| 2012–13* | 0.003 | 0.005 | 0.005 | 0.001 |

| 2014 | 0.004 | 0.006 | 0.005 | 0.001 |

| 2015 | 0.004 | 0.005 | 0.004 | 0.004 |

| 2016 | 0.008 | 0.006 | 0.003 | 0.003 |

| 2017 | 0.004 | 0.008 | 0.004 | 0.001 |

| *Data from 2012 is for the second half of the year only. | ||||

Uranium concentrations were also recently added to the parameters required to be monitored and reported on under the MMER. Table 2.5 presents the average uranium concentrations in treated effluent by metal mining sectors. As shown in table 2.5, the uranium sector had an average concentration of 0.0185 mg/L of uranium in 2017. Uranium mines have elevated natural uranium concentrations compared to other conventional mining operations. By way of comparison and to provide context, the action level in the environmental code of practice and the Saskatchewan regulatory limits for uranium are 0.3 mg/L and 2.5 mg/L, respectively. CNSC staff continue to verify that releases of uranium are controlled and reduced to the extent practicable through reviews of effluent quality data, scrutiny of proposed facility changes that could affect effluent quality, and validation of the effectiveness of licensee programs to minimize releases of contaminants.

| Year | Metal mining sector | |||

|---|---|---|---|---|

| Uranium (mg/L) | Base metals (mg/L) | Precious metals (mg/L) | Iron (mg/L) | |

| 2017 | 0.0185* | 0.0062 | 0.0027 | 0.0002 |

| * Data not available from Environment and Climate Change Canada; value was calculated from licensee annual reports. | ||||

Metal Mining Effluent Regulations performance indicators

The MMER specify the maximum concentration limits in effluent for the following regulated parameters: arsenic, copper, lead, nickel, zinc, radium-226, TSS and an allowable pH range. Effluent must also be non-toxic, which is determined through rainbow trout acute lethality testing. The effluent treatment performance of the four metal mining sectors is compared using the following three performance indicators: compliance with MMER limits for effluent concentration and pH; annual average effluent concentrations in the metal mining sectors; and toxicity test results. These three performance indicators are further described below.

1) Compliance with MMER limits for effluent concentration and pH

Table 2.6 illustrates the number of mines that did not comply with MMER effluent standards for at least one regulated parameter (excluding acute-toxicity tests in 2016). These data are used to assess if compliance with the parameters of MMER is a sector-wide concern.

Two gold metal mines had effluent with radium concentrations above the MMER limit for portions of the year. The uranium mines were in full compliance with the provisions of the MMER.

| Parameter | Mining sector | |||

|---|---|---|---|---|

| Uranium | Base metals | Precious metals | Iron | |

| Arsenic | 0 | 0 | 0 | 0 |

| Copper | 0 | 0 | 0 | 0 |

| Lead | 0 | 0 | 0 | 0 |

| Nickel | 0 | 1 | 0 | 0 |

| Zinc | 0 | 0 | 0 | 1 |

| TSS | 0 | 6 | 4 | 2 |

| Radium-226 | 0 | 0 | 2 | 0 |

| pH range | 0 | 3 | 1 | 3 |

| Mines out of compliance with at least one parameter** | 0 | 10 | 6 | 5 |

| Number of mines | 5 | 47 | 54 | 8 |

|

* 2016 data is the most current sector-specific data available from Environment and Climate Change Canada. ** A mine may have more than one parameter out of compliance; therefore, the number of mines out of compliance with at least one parameter may not equal the sum of the number of mines listed as out of compliance with individual parameters. |

||||

2) Annual average effluent concentrations in the metal mining sectors

Table 2.7 compares the 2016 average effluent concentrations in the metal mining sectors. CNSC staff noted that the effluent concentrations of radium-226 for base metal and precious metal mines are similar to those of uranium mines.

| Parameter** | MMER discharge limits | Uranium | Base metals | Precious metals | Iron |

|---|---|---|---|---|---|

| Arsenic (mg/L) | 0.5 | 0.022 | 0.005 | 0.022 | 0.003 |

| Copper (mg/L) | 0.3 | 0.003 | 0.009 | 0.014 | 0.006 |

| Lead (mg/L) | 0.2 | 0.0002 | 0.003 | 0.001 | 0.003 |

| Nickel (mg/L) | 0.5 | 0.027 | 0.045 | 0.018 | 0.008 |

| Zinc (mg/L) | 0.5 | 0.010 | 0.051 | 0.019 | 0.026 |

| TSS (mg/L) | 15 | 1.0 | 3.3 | 4.2 | 4.3 |

| Radium-226 (Bq/L) | 0.37 | 0.023 | 0.025 | 0.023 | 0.007 |

| pH range | 6.0–9.5 | 7.0 | 7.7 | 7.6 | 7.4 |

|

* 2016 data is the most current sector-specific data available from Environment and Climate Change Canada. ** Uranium is required to be monitored and reported under the MMER. It is not regulated to a specified concentration. |

|||||

3) Toxicity test results

Effluent toxicity is measured using the rainbow trout acute lethality test. As the world standard toxicity test for fresh-water, cool-climate conditions, this test has been part of Canadian regulations and guidelines for four decades. In this test, rainbow trout fingerlings or swim-up fry (0.3 g to 2.5 g wet weight) are reared under controlled conditions. They are then placed in undiluted effluent for 96 hours. If less than half of the fish survive, the effluent is deemed acutely lethal. Effluent must be non-acutely lethal to pass the test as a requirement of MMER.

Table 2.8 displays the number of pass and fail results of rainbow trout acute lethality tests for the metal mining sectors in 2016. The uranium mining metal sector passed all required tests in 2016.

| MMER limit | Uranium | Base metals | Precious metals | Iron | |

|---|---|---|---|---|---|

| Rainbow trout acute lethality test | Pass | 31 | 419 | 492 | 147 |

| Fail | 0* | 2 | 45 | 1 | |

| * Key Lake failed one test, but this test result was later confirmed to be invalid. | |||||

A mine is considered compliant if, throughout the year, its effluent passes all trout acute lethality tests. Table 2.9 summarizes the performance of the metal mining sectors. The uranium mine and mill facilities passed all acute lethality tests from 2012 to 2016.

| Metal mining sector | 2012 | 2013 | 2014 | 2015 | 2016 |

|---|---|---|---|---|---|

| Uranium | 100% | 100% | 100% | 100% | 100% |

| Base metals | 98% | 93% | 98% | 92% | 96% |

| Precious metals | 94% | 86% | 96% | 98% | 91% |

| Iron | 100% | 100% | 71% | 75% | 88% |

2.5 Conventional health and safety

The conventional health and safety SCA covers the implementation of a program to manage workplace safety hazards and protect personnel and equipment. Uranium mines and mills must develop, implement and maintain effective safety programs to promote safe and healthy workplaces and to minimize incidences of occupational injuries and illnesses.

For 2017, CNSC staff rated the conventional health and safety SCA at operating uranium mine and mill facilities as “satisfactory” following acceptable performance in health and safety practices, awareness and performance.

| Cigar Lake | McArthur River | Rabbit Lake | Key Lake | McClean Lake |

|---|---|---|---|---|

| SA | SA | SA | SA | SA |

| SA = satisfactory | ||||

Practices

The CNSC requires licensees to identify potential safety hazards, assess associated risks, and introduce the necessary materials, equipment, programs and procedures to effectively manage, control and minimize these risks. CNSC staff work with the Saskatchewan Ministry of Labour Relations and Workplace Safety to provide regulatory oversight of conventional health and safety in uranium mines and mills. CNSC staff’s compliance verification activities include inspections, reviews of compliance reports and health and safety events.

CNSC staff confirmed that licensees at operating mines and mills implemented effective management of conventional health and safety in their activities. In addition to CNSC staff’s regulatory oversight, the Province of Saskatchewan, through an agreement with the Government of Canada, conducts regular inspections in the areas of occupational health and safety, mine safety and fire protection.

Awareness

CNSC staff observed that the implementation of conventional health and safety programs continued to provide education, training, tools and support to workers (see figure 2.11 for an example). Each facility licensee promotes the idea that safety is the responsibility of all individuals, and this message is reinforced by management, supervisors and workers. Management stresses the importance of conventional health and safety through regular communication, management oversight, and continual improvement of safety systems. Through onsite inspections, CNSC staff have identified a high level of communication and awareness in the area of conventional health and safety. CNSC staff concluded that, in 2017, licensees of operating uranium mines and mills were committed to accident prevention, safety awareness, and a focus on safety culture.

Performance

A key performance measure for conventional health and safety is the number of lost-time injuries (LTIs) that occur per facility. An LTI is a workplace injury that results in the worker being unable to return to work for a period of time. In reviewing each LTI, CNSC staff consider the injury’s severity and frequency rates. Table 2.10 shows the number of LTIs at the operating uranium mines and mills, along with severity and frequency rates.

| Cigar Lake | McArthurRiver | Rabbit Lake | Key Lake | McClean Lake | |

|---|---|---|---|---|---|

| Lost-time injuries1 | 0 | 1 | 0 | 0 | 0 |

| Accident severity rate2 | 0 | 12.1 | 0 | 0 | 67.8 |

| Accident frequency rate3 | 0 | 0.15 | 0 | 0 | 0 |

|

1 An injury that takes place at work and results in the worker being unable to return to work for a period of time.

2 A measure of the total number of days lost to injury for every 200,000 person-hours

worked at the site.

3 A measure of the number of LTIs for every 200,000 person-hours worked at the site.

|

|||||

Appendix I provides more detail on the 2017 LTI at McArthur River and corrective actions taken. The severity rate for McClean Lake is due to events that took place prior to 2017 but resulted in lost time in 2017. Information on these events can be found in section 7.4. CNSC staff and the Saskatchewan Ministry of Labour Relations and Workplace Safety monitor and review each reportable injury to ensure the cause is identified and corrective actions taken are satisfactory. When applicable, injury information is shared among the facilities for lessons learned to improve safety and prevent recurrences.

CNSC staff concluded through their compliance verification activities that the health and safety programs at all uranium mines and mills met regulatory requirements in 2017.

Lost-time injuries: Comparison of the uranium mining sector to other mining sectors in Saskatchewan

Table 2.11 displays the various safety statistics of mining sectors within Saskatchewan. When contractors are excluded, the uranium mining and milling sector exhibits performance similar to other mining sectors for LTIs and frequency rate. The uranium sector comparison excludes contractors because statistics for the other sectors do not include contractors.

| Mining sector | Number of LTIs | Accident frequency rate1 | Accident severity rate2 |

|---|---|---|---|

| Potash (underground) | 9 | 0.2 | 7.3 |

| Solution (potash)3 | 1 | 0.2 | 3.7 |

| Minerals (sodium sulphate, sodium chloride) 3 | 0 | 0 | 0 |

| Hard rock (gold, diamond)3 | 6 | 0.4 | 34.8 |

| Coal (strip mining)3 | 10 | 2.1 | 63.9 |

| Uranium3 | 1 | 0.0 | 23.3 |

| Uranium (including contractors)4 | 1 | 0.0 | 16 |

|

1 A measure of the total number of days lost to injury for every 200,000 person-hours

worked at the site.

2 A measure of the number of LTIs for every 200,000 person-hours worked at the site.

3 Source: Saskatchewan Ministry of Labour Relations and Workplace Safety. 4 Statistics for all the other mining sectors do not include contractors. |

|||

CNSC staff completed a benchmarking effort to compare the injury frequency rate of Saskatchewan uranium mines and mills against national and international mining statistics. One limitation to consider when comparing safety-related statistics is the variation in workplace injury definitions. However, efforts are made where possible to compare and assess licensee performance with respect to relevant national and international benchmarks. Table 2.12 shows various international benchmarks related to workplace frequency rates. The uranium mining and milling sector in Canada exhibits similar, if not, more favorable performance.

| Publication/Standard | Frequency rate | Notes |

|---|---|---|

| Government of Western Australia Department of Mines, Industry Regulation and Safety1 | 2.3, 3.1 |

2.3 across all mining sectors 3.1 in non-metal mining environments; rates are per million hours worked for 2016–17 |

| International Council on Mining and Metals2 | 4.3 | Average rate are per million hours worked for 2016, based on statistics from 27 of the largest international mining companies |

| 2017 Workplace Fatality and Injury Rate Report – Canada3 | 1.9 | Average rate across all Canadian provinces and territories per million hours worked |

| The National Institute for Occupational Safety and Health4 (U.S.) | 1.7 | Average rate per 200,000 hours worked in 2015 |

|

1. Safety performance in the Western Australian mineral industry 2016–17, Government of Western Australia, Department of Mines, Industry Regulation and Safety, 2018. 2. Benchmarking 2016 Safety Data: progress of ICMM Members, International Council on Mining and Metals. 3. 2017 Workplace Fatality and Injury Rate, Tucker. S, University of Regina, 2017. 4. Number and rate of mining nonfatal lost-time injuries by year, 2006–15, The National Institute for Occupational Safety and Health. |

||

3. Cigar Lake Operation

Cameco Corporation is the operator of the Cigar Lake Operation, which is located approximately 660 kilometres north of Saskatoon, Saskatchewan.

The Cigar Lake Operation consists of an underground uranium mine with surface facilities for loading ore slurry into trucks, waste management facilities, water treatment plant, surface freeze plants, administration offices and warehouses. Figure 3.1 shows an aerial view of the Cigar Lake Operation and figure 3.2 provides an annotated map.

The Cigar Lake uranium deposit is mined by mass freezing the orebody and surrounding country rock. Hydraulic water jets then extract the ore as a slurry (mixture of rock and water), which is pumped to surface, loaded into containers and transported 70 kilometres by truck to AREVA’s McClean Lake Operation for milling.

A public Commission hearing was held on April 3, 2013 in Saskatoon, Saskatchewan for the renewal of the Cigar Lake licence. The Commission issued an eight-year licence valid from July 1, 2013 to June 30, 2021.

Table 3.1 shows mining production data for 2013 through 2017. Cigar Lake mine commenced commercial production in spring 2014. Ore production increased during 2015 to achieve current production rate.

| 2013 | 2014 | 2015 | 2016 | 2017 | |

|---|---|---|---|---|---|

| Ore tonnage (Mkg/year)1 | 0.234 | 3.32 | 21.6 | 37.27 | 36.49 |

| Average ore grade mined (%U) | 17.09 | 6.02 | 22.92 | 18.27 | 18.85 |

| Uranium mined (Mkg U/year) | 0.04 | 0.2 | 4.95 | 6.81 | 6.88 |

| Authorized annual production (Mkg U/year) | 9.25 | 9.25 | 9.25 | 9.25 | 9.25 |

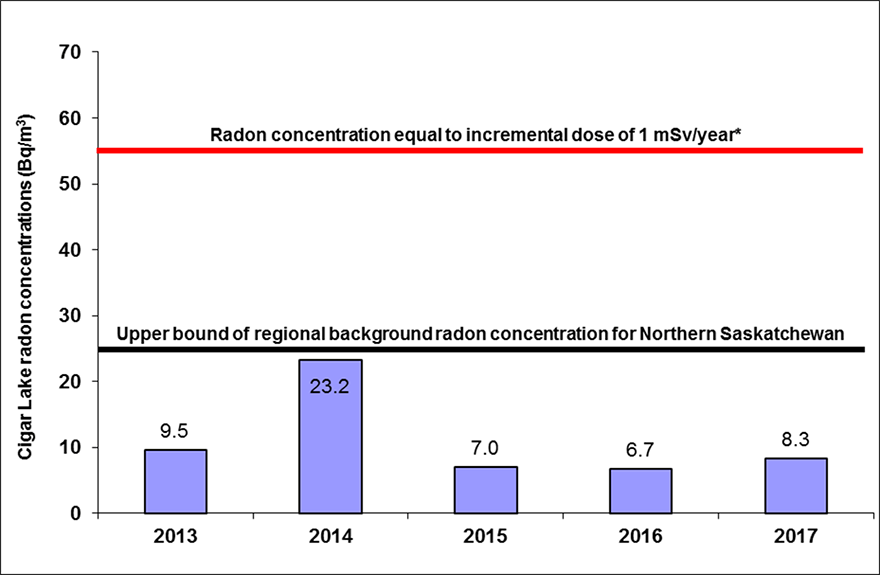

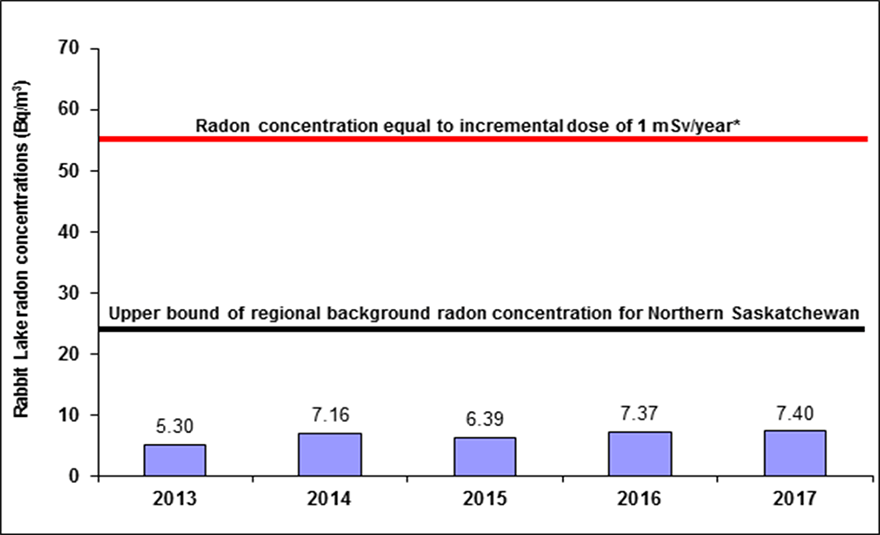

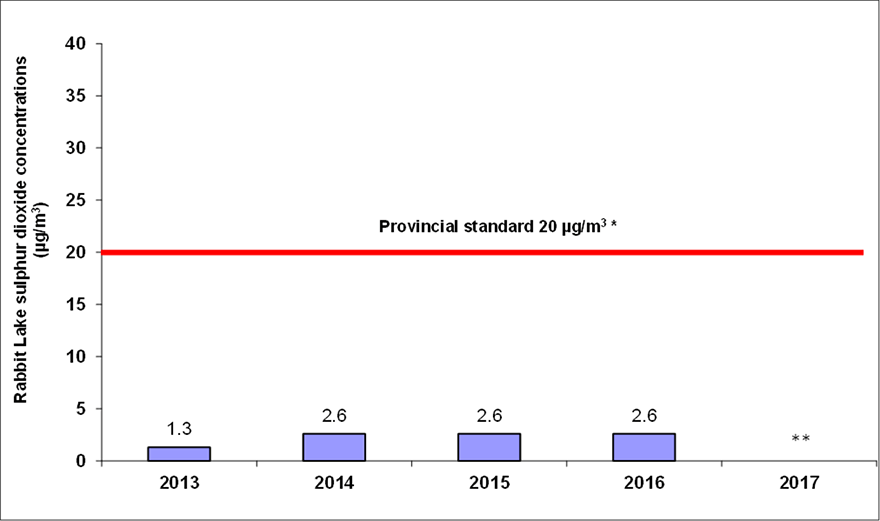

| 1. 1 Mkg = 1,000,000 kg. | |||||