Seventh Canadian National Report for the Joint Convention

Erratum denoting corrections to Canada’s Seventh National Report to the Joint Convention

Following the final submission of this document in fall 2020, Natural Resources Canada identified corrections to the inventory data provided. These details are outlined below. It is important to note that these changes do not impact the report’s conclusions, or Canada continuing to meet its obligations under the articles of the Joint Convention on the Safety of Spent Fuel Management and on the Safety of Radioactive Waste Management.

In Canada, spent fuel and radioactive wastes are currently managed in interim storage facilities that are safe, secure and environmentally sound. Interim storage facilities are continually monitored by licensees and the CNSC to ensure fitness for service.

For questions related to this report or the changes listed below, please contact us.

- Table D.2 contains the total volume of high-level radioactive waste in Canada. The volume is accurate, but the percentage has been corrected to 0.5%. This is due to the correction outlined in point 2a below.

-

Table D.6 contains the total volume of low- and intermediate-level radioactive waste (L&ILW) in Canada.

- The volume of low-level radioactive waste (LLW) has been corrected to 2,524,670 m3. This was a transcription error.

- The percentage of LLW has been corrected to 98.9%. This is due to the correction outlined in point 2a.

- The percentage of intermediate-level radioactive waste has been corrected to 0.6%. This is due to the correction outlined in point 2a.

- Table D.8 contains the inventory of L&ILW in storage in Canada as of December 31, 2019. The volume of LLW at the Cameco Fuel Manufacturing Facility has been corrected to 2,000 m3. This was a transcription error.

Preface

The Joint Convention on the Safety of Spent Fuel Management and on the Safety of Radioactive Waste Management (Joint Convention or Convention) is the only international legally-binding instrument that addresses the safety of spent fuel and radioactive waste management on a global scale. The Contracting Parties to the Joint Convention have made a commitment to apply stringent safety measures, prepare a national report on the measures applied and submit it for review by the other Contracting Parties. As well, they will actively participate in the review meetings of the Contracting Parties.

The Joint Convention was adopted on September 5, 1997, at a diplomatic conference convened by the IAEA in Vienna, Austria. The Convention was opened for signature on September 29, 1997, and entered into force on June 18, 2001. Canada was one of the first countries to ratify the Joint Convention on May 7, 1998.

The Joint Convention is an incentive convention which seeks to promote a high level of safety in the management of spent fuel and radioactive waste through a peer review process, every three years.

The objectives of the Joint Convention are to:

- achieve and maintain a high level of safety worldwide in spent fuel and radioactive waste management

- ensure that there are effective defenses against potential hazards in the course of such activities

- prevent accidents with radiological consequences and mitigate these consequences should they occur at any stage of spent fuel or radioactive waste management

The Joint Convention applies to:

- spent fuel arising from the operation of civilian nuclear reactors

- radioactive waste arising from civilian applications

- uranium mining and milling wastes

- discharges from regulated activities

- specific provisions on disused sealed sources

The structure of the Convention (as outlined in the Articles of the Joint Convention INFCIRC/546, dated December 24, 1997) is as follows:

- Objectives, Definitions and Scope of Application (Articles 1 to 3)

-

Specific Safety Provisions (Articles 4 to 17)

- Articles 4 to 10: Safety of Spent Fuel Management

- Articles 11 to 17: Safety of Radioactive Waste Management

- General Safety Provisions (Articles 18 to 26)

- Miscellaneous Provisions (Articles 27 and 28)

- Meetings of the Contracting Parties (Articles 29 to 37)

- Final Clauses and other Provisions (Articles 38 to 44)

The International Atomic Energy Agency (IAEA) serves as the Secretariat for the Joint Convention. The responsibility of implementing the obligations of the Convention on behalf of the Government of Canada has been delegated to the Canadian Nuclear Safety Commission (CNSC).

This report is Canada’s Seventh National Report for the Joint Convention. The review period for the report is from April 1, 2017, to March 31, 2020. The radioactive waste inventory is reported as of December 31, 2019. The following organizations contributed to the development of this report: the CNSC, Natural Resources Canada, Atomic Energy of Canada Limited, the Nuclear Waste Management Organization, Ontario Power Generation Inc., Bruce Power, New Brunswick Power, Hydro-Québec, Cameco Corporation, Orano, Nordion Inc. and BWX Technologies Inc.

Executive Summary

1.0 Introduction

Canada’s Seventh National Report demonstrates how Canada continued to meet its obligations under the articles of the Joint Convention on the Safety of Spent Fuel Management and on the Safety of Radioactive Waste Management during the reporting period, from April 1, 2017, to March 31, 2020. This report is a collaboration between the Canadian Nuclear Safety Commission (CNSC), federal government departments and industry. It focuses specifically on the progress of long-term management initiatives for spent fuel and radioactive wastes in Canada, revisions and updates to Canada’s Sixth National Report, as well as comments and issues raised at the Sixth Review Meeting which took place in May 2018.

2.0 2019 Integrated Regulatory Review Service mission to Canada

In September 2019, the CNSC hosted an International Atomic Energy Agency (IAEA) Integrated Regulatory Review Service (IRRS) mission to Canada. The scope of the 2019 mission included all activities and facilities licensed by the CNSC, including the regulation of waste management activities. The 2019 IRRS mission confirmed that the CNSC has a strong regulatory framework and continues to ensure the safe operation of nuclear facilities in Canada. The mission to Canada also provided valuable insights; the CNSC and other Canadian federal departments were presented with suggestions, recommendations and a number of good practices to further improve Canada’s oversight of the nuclear industry, including the CNSC’s regulatory framework.

The CNSC developed an action plan to address the findings of the 2019 IRRS mission. On February 18, 2020, the CNSC publicly shared Canada’s response to each recommendation, suggestion and good practice. These actions show Canada’s commitment to addressing the findings of the 2019 IRRS mission, and they will be used to determine whether recommendations and suggestions have been fully addressed prior to the IRRS follow-up mission. The CNSC will continue to share progress related to continuous improvement initiatives resulting from the 2019 IRRS mission in an open and transparent manner. For further information, see section K.5.1.

3.0 Canada’s key highlights and current priorities

The following emerged from the Sixth Review Meeting as Canada’s current priorities and planned measures to improve safety:

-

the modernization of the waste and decommissioning regulatory framework

As part of its ongoing modernization of the regulatory framework, the CNSC is currently completing the development or update of five regulatory documents related to radioactive waste management and decommissioning, including:

- REGDOC-1.2.1, Guidance on Deep Geological Repository Site Characterization

- REGDOC-2.11.1, Waste Management, Volume I: Management of Radioactive Waste

- REGDOC-2.11.1, Waste Management, Volume III: Safety Case for Disposal of Radioactive Waste, Version 2

- REGDOC-2.11.2, Decommissioning

-

REGDOC-3.3.1, Financial Guarantees for Decommissioning of Nuclear Facilities and Termination of Licensed Activities

These regulatory documents are slated for publication in the 2020–21 fiscal year. For further information, see section K.2.1.

-

the implementation of the Impact Assessment Act

The Government of Canada brought in new rules to protect the environment, recognize and respect Indigenous rights, and strengthen the economy through the new Impact Assessment Act (IAA), which came into force on August 28, 2019. The impact assessment process is led by the Impact Assessment Agency of Canada (IAAC) and serves as a planning tool that takes into consideration the whole range of environmental, health, social and economic effects of projects. This regime shifts away from decisions based solely on the significance of effects and focuses instead on whether the adverse effects in areas of federal jurisdiction are in the public interest. For further information, see section K.2.2.

-

the decommissioning and remediation of Atomic Energy Canada Limited (AECL) sites (under the management of Canadian Nuclear Laboratories (CNL))

With the implementation of the government-owned contractor-operated (GoCo) model at AECL sites, CNL continues to significantly accelerate decommissioning and remediation activities. Notable progress has occurred at all sites since the Sixth Review Meeting. This includes:

- the decommissioning and demolition of 77 structures in the supervised and controlled areas at Chalk River Laboratories (CRL), bringing the total number of removed redundant structures to 92 of the more than 120 committed from 2015 through 2026

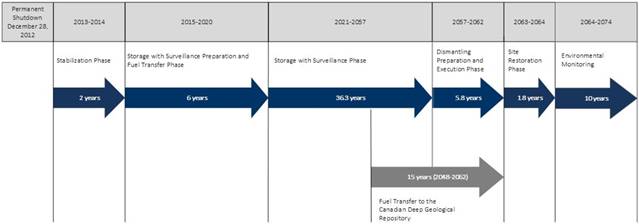

- progress made to place the National Research Universal (NRU) reactor in a storage-with-surveillance state (following end of operation in March 2018)

- the decommissioning licence for Whiteshell Laboratories (WL) site renewed for a period of five years (commencing December 2019)

- the decommissioning of a further 20 redundant structures at the WL site, and overall decommissioning of WL on track for completion by 2027

-

the environmental assessment and licensing of regulatory processes launched in 2017 for:

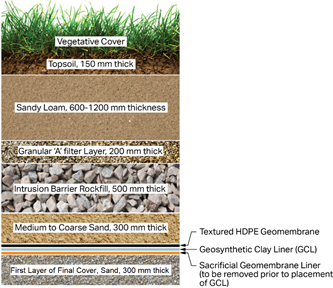

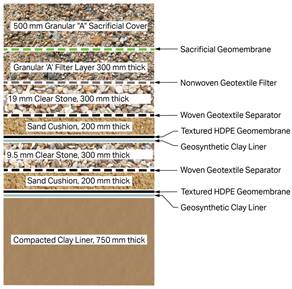

- a near surface disposal facility (NSDF) for the disposal of up to 1,000,000 m3 of low-level radioactive waste (LLW) at CRL. Pending regulatory approval, the proposed disposal facility will be constructed, and the forecasted date of operations is 2024

- the in situ decommissioning of the Nuclear Power Demonstration (NPD) reactor at Rolphton, near CRL. Pending regulatory approval, the site is slated to be decommissioned by 2024

- the in situ decommissioning of Whiteshell Reactor-1 (WR-1) reactor at WL

Following extensive public consultation on the draft environmental impact statements (EISs), extensive comments and questions were received from government agencies, Indigenous communities, civil society organizations and members of the public. After taking into account all of the feedback, CNL submitted revised draft EIS packages for regulatory review (NSDF in December 2019, NPD and WR-1 in March 2020). After the successful completion of the regulatory review, each one will be considered at a CNSC public Commission hearing.

- the preparation of additional interim storage capacity for LLW at CRL while awaiting the start of operations at the NSDF

- the evaluation of ongoing intermediate-level radioactive waste (ILW) storage requirements, including near- to medium-term capacity needs, given that current capacity is limited and the plan is to consolidate the storage of all AECL/CNL ILW at CRL, until ILW disposal becomes available

- the expansion of CRL’s capacity to store dry storage canisters for spent fuel to accommodate the consolidation of spent fuel storage at CRL while awaiting availability at the Adaptive Phased Management (APM) facility of the Nuclear Waste Management Organization (NWMO)

- the completion of the highly enriched uranium (HEU) fuel rod repatriation program to the United States Department of Energy

- the completed commissioning of the fuel packaging and storage facility, and the associated transfer and drying of 96 vulnerable spent fuel packages

-

major progress in the Port Hope Area Initiative (PHAI) cleanup, including:

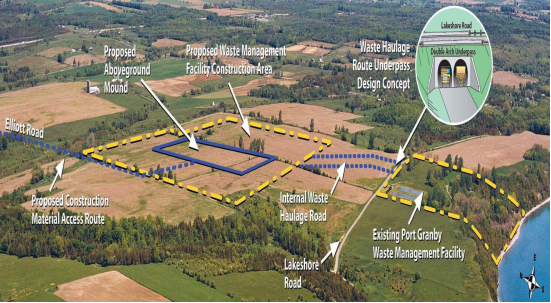

- completed construction of the engineered containment mound (ECM) facilities at both Port Hope and Port Granby

- initiation of cleanup activities within the municipality of Port Hope; closing and capping the Port Hope ECM facility on track for 2026

- nearly completed remediation at Port Granby; closing and capping the Port Granby ECM facility on track for 2021

- the identification of means of disposal for wastes from the cleanup of contaminated sites along the Northern Transportation Route (NTR), enabling the substantial completion of remediation activities by 2026

-

continued progress retrieving and processing stored liquid wastes from several buildings at the CRL site (approximately 3 m3 of liquid wastes removed and immobilized)

For further information, including details of the significant progress made on the above activities since 2015, see section K.2.3.

-

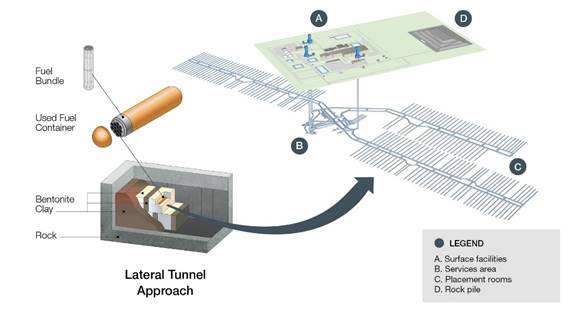

the long-term management of spent fuel and location of an acceptable site in a willing host community for a spent fuel repository

The momentum for implementing the long-term management approach for spent fuel has been sustained ever since the NWMO received its 2007 mandate to implement the APM approach approved by the Government of Canada. When the site selection process was initiated in 2010, a total of 22 communities expressed interest in learning more about the project. As of March 2020, two candidate communities had been identified, one in South Bruce Municipality and one near Ignace, both in Ontario. Studies and community consultation continue in these areas. Indigenous communities are also involved, as facilitated through learning agreements. For more information, see section K.2.4

-

deep geologic repository proposed by Ontario Power Generation (OPG) for its low- and intermediate-level wastes

On August 21, 2017, the federal Minister of Environment and Climate Change asked OPG to update the analysis of the potential cumulative effects the project could have on the Saugeen Ojibway Nation’s cultural heritage and to include a description of the potential effects of the project on the Saugeen Ojibway Nation’s spiritual and cultural connection to the land. Further, the Minister’s letter indicated that the results of the Saugeen Ojibway Nation community process had to inform the analysis. OPG engaged with the community’s leadership to establish a process, which culminated in a community vote. On January 31, 2020, the Saugeen Ojibway Nation voted to not support the project. OPG respects the community’s decision and has formally cancelled the project. OPG has withdrawn its application to the CNSC to construct the deep geologic repository. For further information, see section K.2.5.

-

the discussion about options for an integrated strategy by Canada’s radioactive waste owners under the Radioactive Waste Leadership Forum (RWLF)

Canada’s largest radioactive waste owners – AECL, OPG, Hydro-Québec (H-Q) and New Brunswick Power (NB Power) – and other selected stakeholders continue to meet under the sponsorship of the CANDU Owners’ Group (COG) Radioactive Waste Leadership Forum (RWLF) to discuss opportunities for coordination and collaboration on long-term management matters, including relevant technologies and communication strategies. The RWLF launched a project to produce an integrated radioactive waste strategy for Canada. The first output of this industry-led strategy exercise is expected in the summer of 2020. For further information, see section K.2.6.

4.0 Overarching issues

During the Sixth Review Meeting, overarching issues that arose from cumulative discussions within the country groups were identified. The Contracting Parties agreed that the following issues would be covered in the National Report, along with the measures taken to address these issues:

- the implementation of national strategies for spent fuel and radioactive waste management

- the safety implications of the long-term management of spent fuel

- the linking of long-term management and disposal of disused sealed radioactive sources

- the remediation of legacy sites and facilities

For details on each item, see section K.3.

5.0 Nuclear facilities undergoing decommissioning in Canada

The following nuclear facilities are currently in the process of being decommissioned in Canada:

- CRL

- Douglas Point Waste Management Facility (WMF)

- Gentilly-1 WMF

- Gentilly-2 Nuclear Generating Station (NGS)

- Gunnar mine site

- NPD

- Saskatchewan Research Council (SRC) Safe Low-Power Critical Experiment (SLOWPOKE)-2

- WL

The status of decommissioning activities at these facilities can be found in section D.1.5 and annex 8.

6.0 Conclusion

In Canada, spent fuel and radioactive wastes are currently managed in interim storage facilities that are safe, secure and environmentally sound. Interim storage facilities are continually monitored by the licensees and the CNSC to ensure fitness for service. Canada recognizes that enhanced, long-term management approaches will be required for all its spent fuel and radioactive wastes, and it is making progress developing solutions.

Canada’s Seventh National Report for the Joint Convention on the Safety of Spent Fuel Management and on the Safety of Radioactive Waste Management describes several key initiatives that demonstrate Canada’s commitment to identifying and implementing long-term management approaches that do not place an undue burden on future generations.

Section A – Introduction

.png/object)

A.1 Background

The Government of Canada has jurisdiction over nuclear energy, and Natural Resources Canada (NRCan) is the department responsible for federal nuclear energy policy. The Government of Canada has long funded nuclear research and supported the development and use of nuclear energy and related applications. As a result of this investment:

- Nuclear energy now supplies over 15 percent of Canada’s electricity.

- The nuclear industry is a significant contributor to the Canadian economy, currently generating $17 billion in economic activity and accounting for more than 76,000 highly-skilled direct and indirect jobs.

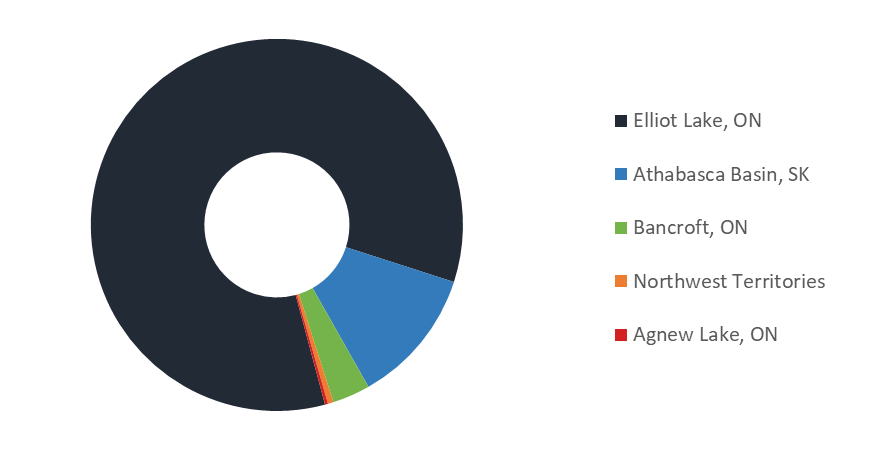

- Canada is the world’s second largest producer and exporter of uranium which ranked seventh among metal commodities in Canada for value of production in 2019.

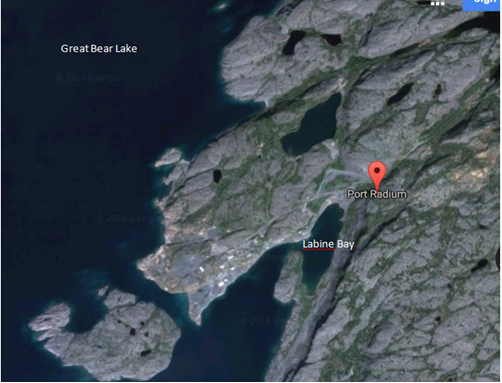

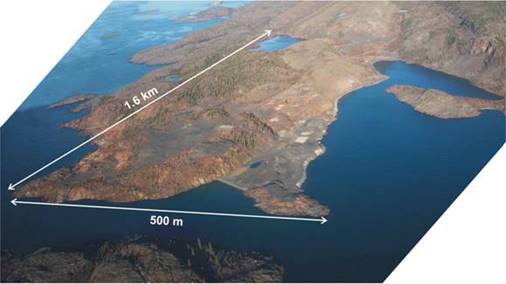

Radioactive waste has been produced in Canada since the early 1930s, when the first radium and uranium mine opened in Port Radium, Northwest Territories. Pitchblende ore was transported from the Port Radium mine to Port Hope, Ontario, where it was refined to produce radium for medical purposes, and later, uranium for nuclear fuel and military applications. Research and development on the application of nuclear energy to produce electricity began in the 1940s at CRL. At present, radioactive waste is generated in Canada from the various stages and uses associated with the nuclear fuel cycle:

- uranium mining and milling

- uranium refining and conversion

- nuclear fuel fabrication

- nuclear reactor operations

- nuclear research

- radioisotope manufacture and use

- radioactive waste and decommissioning

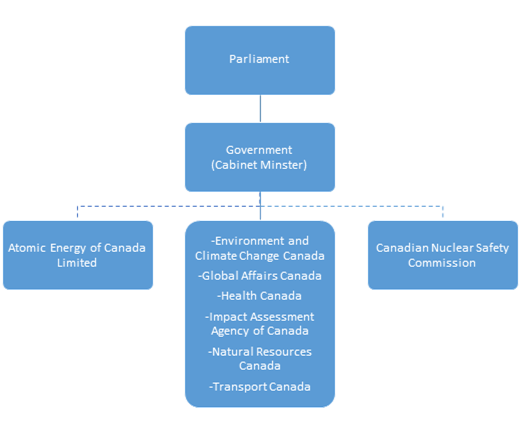

The Government of Canada makes it a high priority to ensure the safety of persons and to protect the environment from the various operations of the nuclear industry, and it has put in place modern legislation that provides the basis for Canada’s comprehensive and robust regulatory regime. Canada’s nuclear regulatory body is the CNSC. In addition to NRCan and the CNSC, the major Government of Canada organizations involved in the Canadian nuclear industry include:

- Atomic Energy of Canada Limited (AECL)

- Environment and Climate Change Canada

- Global Affairs Canada

- Health Canada

- Impact Assessment Agency of Canada (IAAC)

- Transport Canada

Section E.2.7 provides information on Canada’s federal structure and detailed descriptions of the federal institutions involved in nuclear energy.

The following are the centrepieces of Canada’s legislative and regulatory framework for nuclear matters: the Nuclear Safety and Control Act (NSCA), the Nuclear Energy Act (NEA), the Nuclear Fuel Waste Act (NFWA) and the Nuclear Liability and Compensation Act (NLCA). The NSCA is the key piece of legislation that ensures the safety of the nuclear industry and radioactive waste management in Canada. A detailed description of this legislative and regulatory framework is provided in section E.2.1.

Provincial governments are responsible for deciding their energy mix, including the role of nuclear energy. Provincial ministries may play roles in nuclear activities and radioactive waste management; the details of those roles are determined by each province.

A.2 Regulation of nuclear substances

Under the NSCA, one objective of the CNSC is to regulate the development, production and use of nuclear energy and the production, possession and use of nuclear substances, prescribed equipment and prescribed information in order to protect the health and safety of persons, the environment and national security, and to comply with the measures of control and international obligations to which Canada has agreed. A nuclear substance, as defined in section 2 of the NSCA, means: deuterium, thorium, uranium or an element with an atomic number greater than 92; a derivative or compound of deuterium, thorium, uranium or an element with an atomic number greater than 92; a radioactive nuclide; a substance that is prescribed as being capable of releasing nuclear energy or as being required for the production or use of nuclear energy; a radioactive by-product of the development, production or use of nuclear energy; and a radioactive substance or radioactive thing that was used for the development or production, or in connection with the use, of nuclear energy.

Both radioactive wastes and spent fuel contain nuclear substances and therefore are regulated in the same manner as any other nuclear substance. Section B.1.2 describes the policy on managing spent fuel and radioactive waste.

A.3 Canadian philosophy and approach to safety

Canada actively promotes and regulates safety within the nuclear sector. Canada’s approach is based on several factors, including:

- the review of international standards (e.g., IAEA standards and guides) and improvements to CNSC regulatory policies and standards

- consideration for the adoption of international recommendations, such as those regarding radiological dose limits to the public and workers, as outlined in the Recommendations of the International Commission on Radiological Protection (ICRP-103, 2007) issued by the International Commission on Radiological Protection (ICRP)

- consideration for provincial acts and regulations in place for the protection of the environment. For example, limits for controlled releases of gaseous or liquid effluents or solid materials are adopted from complementary regulatory regimes (such as Ontario’s Provincial Water Quality Objectives or Metal Mining Effluent Regulations) or derived from specific licence conditions (such as the derived release limits)

- consideration for the adoption of other standards established by organizations like the Canadian Standards Association (CSA) Group

The CNSC’s regulatory philosophy is based on the following:

- Licensees are directly responsible for managing regulated activities in a manner that protects health, safety, security and the environment, and that conforms with Canada’s domestic and international obligations on the peaceful use of nuclear energy.

- The CNSC is accountable to Parliament and to Canadians for assuring that these responsibilities are properly discharged.

The CNSC, therefore, ensures that the regulated parties are informed about requirements and provided with guidance on how to meet them, and then it verifies that all regulatory requirements are and continue to be met.

A.4 Continuous improvement

The CNSC is committed to the continuous improvement of both its internal operations and its regulation of the Canadian nuclear industry. Thus, the CNSC requires licensees to strive to further reduce the risks associated with their licensed activities on an ongoing basis. It assesses how licensees manage risk during both normal operations and in response to potential accident conditions, and how they apply principles like as low as reasonably achievable (ALARA) and defence in depth. In its assessments, the CNSC considers how licensees continuously evaluate, manage and further reduce uncertainties with respect to hazards and safety issues. This also includes assessing how licensees consider additional safety and mitigation options as techniques and technologies evolve.

A.5 Defence in depth

CNSC requirements necessitate the implementation of defence in depth in the design, construction and operation of nuclear facilities or undertaking of nuclear activities. With defence in depth, more than one level of defence (i.e., protective measure) is in place for a given safety objective, so that the objective will still be achieved even if one of the protective measures fails.

To achieve this, multiple independent levels of defence must be put into place to the extent practicable, taking organizational, behavioural and engineered safety and security elements into account, so that no potential human or mechanical failure relies exclusively on a single level of defence.

A.6 Protection of the environment

Environmental protection is a shared federal-provincial responsibility. The CNSC cooperates with other jurisdictions and departments, and where appropriate, enters into formal arrangements to protect the environment more effectively and to coordinate regulatory oversight.

The CNSC’s environmental protection mandate includes design objectives and best practices to minimize or eliminate the release of nuclear or hazardous substances to the environment. Environmental protection measures are commensurate with the level of risk associated with the activity. The CNSC determines whether a licensee or applicant will make adequate provision to protect the environment against unreasonable risk and verifies compliance with the associated regulatory requirements.

A.7 Protection of the health and safety of persons

The CNSC sets dose limits that are within protective health limits and establishes regulations that set requirements to prevent unreasonable risk to the health and safety of persons. These limits are described in the Radiation Protection Regulations (RPR) and are consistent with the recommendations of the ICRP. The Regulations also require every licensee to implement a radiation protection program that takes the principle of ALARA into consideration. In addition to radiological hazards, regulating to prevent unreasonable risk to the health and safety of persons addresses conventional health and safety hazards.

A.8 Protection of national security

To prevent risk to national security, the CNSC works closely with nuclear facility operators, law enforcement and intelligence agencies, international organizations and other governmental departments to ensure that nuclear substances and facilities are adequately protected. Nuclear security in Canada is aided by the Nuclear Security Regulations (NSR). These regulations set out detailed security requirements for licensed nuclear facilities and other regulated activities.

A.9 International obligations

The CNSC participates in international forums to provide global nuclear leadership and to benefit from international experience and best practices. It also participates in undertakings implemented by the IAEA, the ICRP and other international organizations, and in activities under certain treaties, such as the Joint Convention.

These international activities help inform the CNSC’s decision-making processes to:

- understand and compare various ways of evaluating and mitigating risks

- share research and operational experience

A.10 Nuclear non-proliferation

The CNSC is responsible for implementing Canada’s nuclear non-proliferation commitments and government policy to:

- assure Canadians and the international community that Canada’s nuclear exports do not contribute to the development of nuclear weapons or other nuclear explosive devices

- promote a more effective and comprehensive international nuclear non-proliferation regime

The international Treaty on the Non-Proliferation of Nuclear Weapons (the non-proliferation treaty (NPT)) is the cornerstone of Canada’s efforts to promote its objectives of international disarmament, non-proliferation, and the peaceful use of nuclear energy. NPT commitments to which Canada has agreed include:

- to not receive, manufacture or acquire nuclear weapons or other nuclear explosive devices

- to accept IAEA safeguards on all nuclear material for peaceful use in Canada

- to ensure that Canada’s nuclear material exports are subject to IAEA oversight

The CNSC implements these commitments through the NSCA and its associated regulations, including the Nuclear Non-proliferation Import and Export Control Regulations (NNIECR).

A.11 Safeguards

The term “safeguards” refers to the measures taken by the IAEA, in accordance with the NPT, to verify that nuclear material is not diverted from peaceful uses to develop nuclear weapons. The safeguards agreement between the Government of Canada and the IAEA give the IAEA the right and obligation to monitor Canada’s nuclear-related activities, and to verify nuclear material inventories and flows in Canada.

Through its regulatory oversight, the CNSC ensures that all applicable licensees have safeguards programs in place to allow for:

- monitoring and reporting on nuclear material and activities

- providing IAEA safeguards inspectors with access to areas where nuclear material is stored and access to certain specified nuclear-related manufacturing and research activities

- providing operational and design information for nuclear facilities to the IAEA

Where required by the safeguards agreements, the CNSC compiles licensee information and submits it to the IAEA on behalf of the Government of Canada. The CNSC has also cooperated with the IAEA to develop new safeguards approaches for Canadian facilities, and it contributes to efforts to strengthen IAEA safeguards internationally.

A.12 Main safety issue

The main safety issue that this report begins to address is the long-term management of spent fuel and radioactive wastes.

In Canada, developing and implementing the long-term management of radioactive wastes is the responsibility of the waste owner. Currently, interim storage of all waste forms is being conducted in a safe manner. The Canadian nuclear industry and the Government of Canada are developing long-term waste management solutions that will protect health, safety, security and the environment. Key initiatives underway are described in section K of this report. Some of the most important challenges will be to bring these initiatives to fruition and to develop and implement appropriate long-term solutions that inspire and uphold the public’s confidence.

The long-term management of radioactive waste from past practices has been a challenge for the federal and provincial governments as they develop and implement appropriate remedial strategies and long-term waste management solutions. Several initiatives have been completed or are underway to address these sites, as described in sections H.2.1 and K.3.4.

A.13 Main themes in Canada’s Seventh National Report

The main themes in this report are as follows:

- The Government of Canada’s departments and agencies and the nuclear industry have roles and responsibilities – confirmed in the Government of Canada’s Radioactive Waste Policy Framework – to ensure the safe management of spent fuel and radioactive wastes.

- The primary responsibility for safety rests with the licensees. All licensees take their responsibility for safety seriously and are able to raise adequate revenues to support safe operations.

- The Canadian safety philosophy and requirements, applied through the regulatory process, ensure that the risk to workers, the public and the environment that is associated with spent fuel management and radioactive waste management is kept as low as reasonably achievable (ALARA), with social and economic factors taken into consideration.

- The Canadian regulatory body has sufficient independence, authority and resources to ensure compliance with and enforcement of regulatory safety requirements that pertain to the management of spent fuel and radioactive wastes.

- The industry and various levels of government are engaged in a number of initiatives to develop and implement long-term solutions for spent fuel and radioactive wastes, and for the cleanup of wastes from past practices like uranium mining and processing.

Section B – Policies and Practices

.png/object)

B.1 Reporting (Article 32(1))

This section addresses the obligations under Article 32(1) of the Joint Convention.

ARTICLE 32. REPORTING

-

In accordance with the provisions of Article 30, each Contracting Party shall submit a national report to

each review meeting of Contracting Parties. This report shall address the measures taken to implement each

of the obligations of the Convention. For each Contracting Party the report shall also address its:

- spent fuel management policy;

- spent fuel management practices;

- radioactive waste management policy;

- radioactive waste management practices;

- criteria used to define and categorize radioactive waste

B.1.1 Classification of radioactive waste in Canada

Established in 1919, the Canadian Standards Association (now called the CSA Group) is a not-for-profit organization composed of representatives from the government, industry and consumer groups. Its primary product is safety and performance standards, including those for electronic and industrial equipment, boilers and pressure vessels, compressed gas handling appliances, environmental protection and construction materials. The CSA Group also provides training materials and information products.

The CSA Group, in collaboration with industry, government and the CNSC, developed a standard that includes a radioactive waste classification system (CSA N292.0, General principles for the management of radioactive waste and irradiated fuel), which takes into account the IAEA’s general safety guide GSG-1, Classification of Radioactive Waste, along with the needs of the Canadian industry. The second edition was published in 2019, superseding the previous edition published in 2014. CSA N292.0-19 recognizes four main classes of radioactive waste:

- high-level radioactive waste (HLW)

- intermediate-level radioactive waste (ILW)

- low-level radioactive waste (LLW)

- uranium mine and mill tailings

Subclasses for LLW are also identified to provide better guidance on the appropriate waste management needs.

The radioactive waste classification system is organized according to the degree of containment and isolation required to ensure safety in the short and long terms. The classification system also takes into consideration the hazard potential of different types of radioactive wastes.

A definitive numerical boundary between the various categories of radioactive waste – primarily between LLW and ILW – cannot be provided, because activity limitations differ between individual radionuclides and radionuclide groups, and will be dependent on short- and long-term safety-management considerations. A contact dose rate of 2 mSv/h has been used as guidance in some cases to distinguish between LLW and ILW.

The following sections provide an overview of the four main classes of radioactive waste in Canada.

B.1.1.1 High-level radioactive waste

HLW is used or irradiated nuclear fuel that has been declared radioactive waste and/or waste that generates significant heat (typically more than 2 kW/m3) via radioactive decay. HLW typically has levels of activity concentration that range from 104 to 106 TBq/m3.

In Canada, “irradiated nuclear fuel” or “used nuclear fuel” are more accurate terms for spent fuel, because discharged fuel is considered a waste material even when it is not fully spent. Despite the name difference, in this report, the term “spent fuel” is used, and it is consistent with the terminology used in the Joint Convention.

Spent fuel is associated with penetrating radiation; thus, shielding is required. Spent fuel also contains significant quantities of long-lived radionuclides, necessitating long-term isolation. Waste forms derived from spent fuel (e.g., nuclear fuel reprocessing wastes) can also exhibit similar characteristics and are therefore considered HLW.

Placement in deep, stable geological formations is considered the preferred option for the long-term management of HLW.

B.1.1.2 Intermediate-level radioactive waste

ILW generally requires little or no heat dissipation during its handling, transportation and long-term management. However, because of its total radioactivity level, it may be necessary to consider of the implications of ILW short-term heat generation. Because of its long-lived radionuclides, ILW generally requires a higher level of containment and isolation than can be provided in near-surface repositories.

B.1.1.3 Low-level radioactive waste

LLW contains material with radionuclide content above established clearance levels and exemption quantities, but generally has limited amounts of long-lived activity. For orientation purposes only, a limit of 400 Bq/g on average (and up to 4,000 Bq/g for individual waste packages) for long-lived alpha emitting radionuclides can be considered in the classification process. For long-lived beta and/or gamma emitting radionuclides, such as carbon-14, chlorine-36, nickel-63, zirconium-93, niobium-94, technetium-99 and iodine-129, the allowable average activity concentrations can be considerably higher (up to tens of kBq/g) and can be specific to the site and disposal facility. LLW requires isolation and containment for up to a few hundred years.

B.1.1.3.1 Very-short-lived low-level radioactive waste

Very-short-lived low-level radioactive waste (VSLLW) is waste that can be stored for a decay period of not more than a few years (a time frame of two years is commonly used) and subsequently cleared for release. VSLLW includes radioactive waste containing only short half-life radionuclides typically used for research and biomedical purposes. Examples of such radioactive waste are iridium-192 and technetium-99m sources and radioactive wastes containing similar short half-life radionuclides from industrial and medical applications.

The main criterion used to identify VSLLW is the half-life of the predominant radionuclides. In general, the management of VSLLW should only be applied to radionuclides with a half-life of 100 days or less.

B.1.1.3.2 Very-low-level radioactive waste

Very-low-level radioactive waste (VLLW) has a low hazard potential and does not meet the criteria for exemption. Long-term waste management facilities for VLLW do not need a high degree of containment and/or isolation; a near-surface repository with limited regulatory control is generally suitable. Typically, VLLW includes bulk material like low-activity soil and rubble, as well as some uranium wastes.

B.1.1.4 Uranium mine and mill tailings

Uranium mine and mill tailings are a specific type of radioactive waste generated during the mining and milling of uranium ore and the production of uranium concentrate. In addition to tailings, mining activities typically result in the production of large quantities of waste rock as workings are excavated to access the ore body. The wastes contain long-lived activity that do not decrease significantly over extended time periods. In general, long-term management in near-surface facilities adjacent to mines and mills is the only practical option for these wastes, given the large volumes of waste generated in mining and milling operations.

B.1.2 Spent fuel and radioactive waste management policy

In Canada, matters that relate to nuclear activities and substances are under the jurisdiction of the Government of Canada. Natural Resources Canada (NRCan) has been charged with setting Canada’s nuclear policies, including those that concern radioactive wastes. The Government of Canada’s Radioactive Waste Policy Framework establishes the roles and responsibilities of the Government of Canada, and of the waste producers and owners. In particular:

- The federal government will ensure that radioactive waste disposal is carried out in a safe, environmentally sound, comprehensive, cost-effective and integrated manner.

- The federal government’s responsibility is to develop policy, regulate and oversee producers and owners to ensure that they comply with legal requirements and meet their funding and operational responsibilities in accordance with approved waste disposal plans.

- Based on the “polluter pays” principle, the waste producers and owners are responsible for funding, organizing, managing and operating the disposal and other facilities required for their wastes. This recognizes that arrangements may be different for nuclear fuel waste, LLW and uranium mine and mill tailings.

Under Canada’s current legislative and regulatory framework, spent fuel is considered to be another form of radioactive waste. As a result, legislation and policies on managing radioactive waste apply equally to spent fuel and other forms of radioactive waste.

In September 2019, the IAEA undertook an IRRS mission and concluded that Canada has a comprehensive framework for nuclear and radiation safety. It also noted six good practices for other countries to consider. The review included a recommendation that the government enhance the existing policy and establish an associated strategy to give effect to the principles stated in the Government of Canada’s Radioactive Waste Policy Framework.

As part of Canada’s management response to the recommendation, the Government of Canada will review its existing policy for radioactive waste and consider ways to enhance it to give effect to the principles stated in the Radioactive Waste Policy Framework, including establishing an associated strategy. NRCan will undertake this review as the lead government department responsible for developing and implementing federal nuclear energy policy in Canada.

In December 2018, the CNSC issued regulatory document REGDOC-2.11, Framework for Radioactive Waste Management and Decommissioning in Canada which gives an overview of the governance and regulatory framework for radioactive waste management and decommissioning in Canada. This overview provides the basis for the other documents in the CNSC’s waste management series of regulatory documents. REGDOC-2.11 outlines the philosophy that governs the CNSC’s regulation of radioactive waste and is fully consistent with the federal Radioactive Waste Policy Framework. REGDOC-2.11 identifies the need for the long-term management of radioactive and hazardous wastes that arise from licensed activities.

REGDOC-2.11 includes a policy statement in which radioactive waste is defined as any form of waste material that contains a nuclear substance, as defined in the NSCA. This definition is sufficiently comprehensive to include spent fuel without any other special consideration. The policy indicates that, when making regulatory decisions about the management of radioactive waste, the CNSC will seek to achieve its objectives by considering certain key principles in the context of the facts and circumstances of each case, as follows:

- The generation of radioactive waste is minimized to the extent practicable by the implementation of design measures, operating procedures and decommissioning practices.

- The management of radioactive waste is commensurate with its radiological, chemical and biological hazard to the health and safety of persons, to the environment and to national security.

- The assessment of future impacts of radioactive waste on the health and safety of persons and the environment encompasses the period of time during which the maximum impact is predicted to occur.

- The predicted impacts on the health and safety of persons and the environment from the management of radioactive waste are no greater than the impacts that are permissible in Canada at the time of the regulatory decision.

- The measures needed to prevent unreasonable risk to present and future generations from the hazards of radioactive waste are developed, funded and implemented as soon as reasonably practicable.

- The transborder effects on the health and safety of persons and the environment which could result from the management of radioactive waste in Canada are not greater than the effects experienced in Canada.

The principles contained in REGDOC-2.11 are consistent with those recommended by the IAEA. REGDOC-2.11 also recognizes the CNSC’s commitment to optimizing regulatory effort, stating that the CNSC should consult and cooperate with provincial, national and international agencies to:

- promote harmonized regulation and consistent national and international standards for the management of radioactive waste

- achieve conformity with the measures of control and international obligations to which Canada has agreed concerning radioactive waste

B.1.3 Spent fuel management practices

B.1.3.1 Spent fuel in Canada

B.1.3.1.1 Spent fuel generated at nuclear power reactors

In Canada, spent fuel is stored in wet and dry states. When the fuel first exits a power reactor, it is placed in water-filled bays. Water cools the fuel and shields the radiation. After several years in the bays – six to 10 years, depending on site-specific needs and organizational administrative controls – and when the associated heat generation has diminished, the spent fuel can be transferred to a dry storage facility. These dry storage facilities employ large, reinforced concrete canisters or containers. Each nuclear power plant (NPP) site in Canada has enough space to store all the spent fuel produced during the operating life of the station. A 600-megawatt CANDU nuclear reactor produces approximately 90 tonnes of heavy metal spent fuel annually.

In Canada, all spent fuel is stored at the site where it was produced, with the following exceptions:

- small quantities of spent fuel that are transported to research facilities for experimental or examination purposes and stored at those facilities

- the fuel from the NPD reactor, which is in dry storage at the nearby CRL site

All Canadian nuclear power reactors were constructed with on-site spent fuel storage bays or water pools. Spent CANDU fuel is initially stored in light water with continuous heat removal capability. Criticality cannot be achieved with CANDU fuel in light water, independent of temperature. Spent fuel is then stored in dry storage facilities after a specified period of decay. Secondary or auxiliary bays were constructed at the Pickering A (Units 1 to 4) Nuclear Generating Station (NGS) and the Bruce A and Bruce B NGSs for additional storage. Since 1990, dry storage technology has been chosen at all the reactor sites for additional on-site interim storage.

All CANDU fuel bundles are fabricated from natural uranium oxide pellets contained in a zirconium-alloy (zircaloy-4) tube (cladding). Variations occur in the overall length, diameter and weight of the fuel bundles between reactors; the information that follows is based on averaged data. Normally, there are 30 uranium oxide pellets per fuel bundle element. The maximum nominal bundle diameter is 102 mm, with an overall bundle length of 495 mm. The weight of a nominal bundle is 23.6 kg, of which 21.3 kg is uranium oxide. Approximately 19.2 kg can be attributed to uranium (without the oxygen component).

Each year, 4,500 to 6,000 fuel bundles per reactor are added to the wet storage bays, based on 80 to 95 percent full power reactor operation.

B.1.3.1.2 Spent fuel generated at research reactors

As of March 2020, there were four operating research reactors in Canada:

- Royal Military College of Canada (RMC) (SLOWPOKE-2, 20 KW, Kingston, Ontario)

- École Polytechnique de Montréal (SLOWPOKE-2, 20 KW, Montréal, Quebec)

- McMaster Nuclear Reactor (pool-type, 5 MW, Hamilton, Ontario)

- Zero Energy Deuterium-2 (ZED-2) (pool-type, 200 W, Chalk River, Ontario)

These reactors use low-enriched uranium (LEU) fuel.

The University of Alberta’s SLOWPOKE-2 reactor in Edmonton, Alberta, was decommissioned in 2017, and the site was released for unrestricted use in 2018. The SRC’s SLOWPOKE-2 reactor in Saskatoon, Saskatchewan, is undergoing decommissioning as of March 2020. These two reactors were using HEU fuel, and the fuel cores were repatriated to the U.S., the fuel’s country of origin.

The ZED-2 reactor is operated occasionally and is mainly used for testing prototype fuel to determine fuel characteristics. ZED-2 uses mostly natural uranium, but it can use various fuel types, depending on the purpose. Spent fuel from ZED-2 is stored on-site at Chalk River Laboratories (CRL).

All SLOWPOKE-2 cores are pre-assembled and cannot be modified by the licensee. The cores can last 30 years (or more depending on usage) with the addition of beryllium reflector shims to compensate for reactivity decreases in fuel. When the added shims can no longer compensate for the decreased reactivity, the entire core can be replaced. Although the SLOWPOKE-2 reactors initially used HEU fuel, they were subsequently converted to LEU or decommissioned, and the spent HEU cores were returned to the U.S., the fuel’s country of origin. The LEU cores, once spent, are sent to CRL for storage.

Spent fuel from the McMaster Nuclear Reactor is shipped to a licensed spent fuel management facility in the U.S. when a sufficient quantity has accumulated in the pool, approximately once a year.

In 2010, a project was undertaken to repatriate all inventories of spent HEU fuel from Canada to the U.S. As of 2019, all HEU from the SLOWPOKE research reactors had been returned to the U.S.

B.1.3.1.3 Fuel generated for medical isotope production

This type of fuel is not included in the report because, once spent, it is reprocessed to extract medical isotopes. According to Article 3(1), this activity falls outside the scope of the Joint Convention.

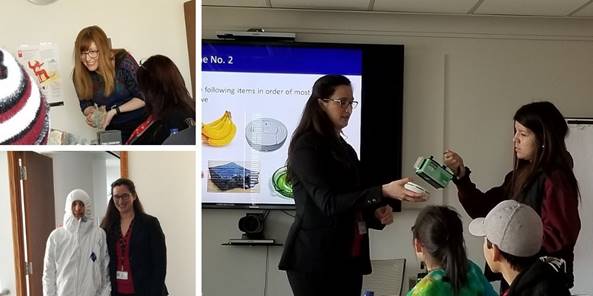

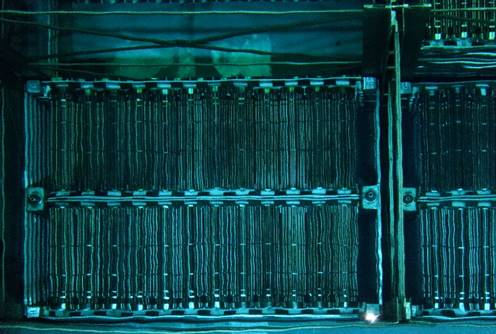

B.1.3.2 Wet storage technology

Spent fuel discharged from a nuclear reactor is stored initially in wet bays or water pools (see figure B.1). Wet bays, together with the cooling and purification systems, contain the spent fuel and associated radioactivity and provide good heat transfer to control fuel temperatures. The water also provides shielding and allows access to the fuel, via remotely-operated and automated systems for handling and examination. The bay structure and structural elements (such as fuel containers and stacking frames) provide mechanical protection.

The purpose of the wet storage bays and their cooling and purification systems is to:

- provide safe temporary storage and handling of irradiated fuel, including defective bundles

- remove heat ejected by irradiated fuel bundles at a rate sufficient to keep water temperature within the design limits of the bay walls and floor

- reduce radioactivity in the bay to acceptable levels

- keep bay water in a demineralized state to minimize the corrosion of metal surfaces

- automatically control water levels

The walls and floors of CANDU reactor water pools are constructed of carbon-steel reinforced concrete approximately two metres thick. Inner walls and floors are lined with a watertight liner consisting of stainless steel or a fibreglass-reinforced epoxy compound, or a combination of the two. The bay structure is seismically qualified so the structures and bay components maintain their structural form and support function both during and following a design-basis event (such as an earthquake, for example). Other structural design considerations include load factors and load combinations (including thermal loads) for which upper and lower temperature limits have been established.

Figure B.1: Wet storage at the Bruce NGS

.jpg/object)

B.1.3.2.1 Bay liners

The bays are designed to prevent bay water from leaking into the environment through any possible defects in the concrete. The bay’s inner liner is the primary barrier against outward leakage. The bays also have a leakage collection system to ensure any leakage that does occur is captured and directed to a controlled drainage system. The design has provisions for leak detection and tracking.

B.1.3.2.2 Storage in wet bays

A number of designs are used to hold spent fuel for storage in wet bays, all of which meet IAEA safeguards requirements. Storage in the wet bays is seismically qualified and all handlings are monitored by the IAEA.

At Ontario Power Generation (OPG) and Bruce Power (BP) facilities, baskets, trays and modules are stacked vertically in the bays within seismically qualified stacking frames. OPG and BP use a standardized site-specific, storage-transportation module that stores the fuel compactly. Fuel stored in baskets and trays is transferred to modules prior to being loaded into dry fuel storage containers. To reduce handling, the storage-transportation module is also suitable for holding the fuel during transportation. The modules are loaded directly into dry fuel storage containers and stacked, as shown in figure B.4.

Hydro-Québec (H-Q) stores the spent fuel horizontally on racks, in its wet bays. Before it is transferred to dry storage, the spent fuel is transferred in fuel baskets using pneumatic tools.

NB Power transfers the spent fuel from the reactor to the spent fuel reception bay where the fuel is stored in trays. From the reception bay it is transferred to the spent fuel storage bay and remains in the trays for its seven-year storage. From this location, the spent fuel is loaded into baskets and transferred to dry storage.

B.1.3.2.3 Water pool chemical control

In all storage bays, water is circulated through cooling and purification circuits. A combination of ion exchange columns, filters and surface skimmers is used to control water purity within design limits. A typical purification system also includes resin traps, sample points and instrumentation to indicate when filters and ion exchange columns are exhausted and when resin traps must be cleaned out. Water-pool chemical control aims to:

- minimize corrosion of metal surfaces

- minimize the level of radioisotopes in the water and reduce radiation fields and radioiodine levels in the bay area

- maintain clarity of the bay water for ease of bay operation

Demineralized water is used to ensure purity.

B.1.3.3 Experiences with wet storage

Early operating experiences at the CRL research reactor spent fuel bays (which have been in operation since 1947) and at the NPD and Douglas Point reactors have provided a basis for the successful operation of spent fuel bays in the current generation of power reactors. Those experiences, along with the development of high-density storage containers, inter-bay fuel transfers and remote handling mechanisms, contributed to establishing current safe-storage techniques. At CRL, the only wet storage still in operation are the NRU reactor rod bays.

Good chemical control has been achieved in Canadian spent fuel bays. Radioactivity in the water has been kept to very low or non-detectable levels, resulting in low radiation levels in the bay area. Overall fuel bundle defect rates are low. During early operations, defective fuel was “canned” (i.e., stored in a sealed cylinder). With more operating experience, canning has been found to be generally unnecessary due to the minimal release of fission products from most defective bundles. In some cases, known defective fuel is held temporarily in the fuel handling system before being passed to the bay. Known defective fuel is generally stored in a designated part of the fuel bay.

As noted above, an epoxy polymer liner is in place at a number of the stations. With extended operating lifetimes and continual exposure to radiation, some radiation-induced deterioration of the liner has been detected at the Pickering NGS (where the first epoxy liner was used). Potential leaks in the Unit 1–4 primary bay were located and repaired before Pickering Units 1 and 4 were returned to service after an extended shutdown. Techniques have been developed for underwater repairs that use an underwater-curing epoxy. Extensive repairs were completed in 2002–03 at various locations in the Pickering 1–4 primary bay. Similar repairs were conducted for the Pickering Unit 5–8 primary bay in 2016–17.

The Bruce A NGS also utilizes an epoxy polymer liner, which has experienced minor deterioration over time. A comprehensive inspection was completed in 2018 to assess the health of the liner. There had been no leaks present and continued inspections are conducted frequently to ensure deterioration does not increase.

B.1.3.4 Dry storage technology

After a cooling period of six to 10 years in a wet bay (the exact cooling period is site-specific), spent fuel is then transferred to an interim dry storage facility.

Currently, three basic designs are used for the dry storage of spent fuel in Canada:

- AECL concrete canister

- AECL modular air-cooled storage (MACSTOR) system

- OPG dry storage container (DSC)

All transfers of spent fuel to dry storage are subject to IAEA surveillance. All loaded OPG DSCs in interim storage are also under the surveillance of the IAEA through the application of a dual sealing system.

B.1.3.4.1 AECL concrete canister

The AECL concrete canister fuel storage program was developed at WL in the early 1970s to demonstrate that dry storage for spent reactor fuel was a feasible alternative to water pool storage. Owing to the success of the demonstration program, concrete canisters were used to store WR-1 spent fuel. Further, the AECL concrete canister design is used at CRL for the dry storage of fuel bundles from the NPD reactor, the Point Lepreau NGS and the partially decommissioned Douglas Point (see figure B.2) and Gentilly-1 reactors.

The canister system comprises the following main components:

- fuel basket

- shielded workstation

- transfer flask

- concrete canister

The fuel basket is constructed of stainless steel and comes in three designs:

- a design to hold 54 bundles (used for fuel from Douglas Point and NPD)

- a design to hold 38 bundles, each of which is placed over a basket pin (used for fuel from Gentilly-1)

- a design to hold 60 bundles (used for fuel from Point Lepreau)

A shielded workstation is equipped to dry a loaded fuel basket and to weld the basket cover to the basket base plate and central post assembly. It is composed of a number of sub-assemblies used for lifting, washing, drying, seal welding and inspecting the spent fuel baskets. The shielding provided by the workstation is sufficient to reduce the radiation fields and ensure the safety of the workers.

The fuel basket transfer flask is used to shield the basket when it is moved from the shielded workstation at the NPP to the dry storage canister at the waste management facility (WMF).

The concrete canister is a cylindrical, reinforced concrete shell with an internal liner. To provide additional shielding, a two-piece loading plug is used until the canister is filled. A provision is made for IAEA safeguard seals to be placed on top of the canister plug so the plugs cannot be removed without breaking the seals.

Two small-diameter pipes allow the air between the liner and the fuel baskets to be monitored to confirm the integrity of the confinement barriers. The concrete canisters are supported on reinforced concrete foundations above the water table. Each canister holds six, eight, nine or 10 baskets, depending on the specific needs of the station.

The transfer of spent fuel from the storage bays to dry storage canisters always begins with the oldest fuel. Therefore, the nominal age of the spent fuel in dry storage is usually older than seven years, which adds a measure of conservatism to the assumptions and overall safety of the dry storage of spent fuel.

Three barriers (defence in depth) ensure the containment of the radioactive products:

- fuel sheath

- fuel basket

- internal liner

Figure B.2: AECL concrete canisters at Douglas Point

.jpg/object)

B.1.3.4.2 AECL MACSTOR system

The MACSTOR system is a variant of the concrete canister storage technique. MACSTOR modules are currently installed and being operated at the Gentilly-2 NGS site in Quebec, the Cernavoda site in Romania and the Qinshan site in China.

The original MACSTOR design (MACSTOR-200) is a secure, reinforced concrete structure that houses 20 vertical steel cylinders, each of which holds 10 sealed baskets of 60 spent fuel bundles. Each module can store 12,000 bundles of spent fuel. Each cylinder is secured to the top slab of the module, and two sampling pipes that extend to the outside of the MACSTOR module are provided at its base. These pipes allow for confirmation of the integrity of confinement. The MACSTOR-200 is used at the Gentilly-2 site (see figure B.3) and the Cernavoda site.

The newer design, MACSTOR-400, can store twice as much fuel with a marginal increase in construction costs when compared to the MACSTOR-200. The MACSTOR-400 houses 40 vertical steel cylinders, each of which can hold 10 sealed baskets of 60 fuel bundles. In total, the module can store 24,000 bundles of spent fuel. The MACSTOR-400 is used at the Qinshan site and will be used at the Cernavoda site.

The heat of the spent fuel is dissipated primarily by natural convection through ventilation ports that extend through the concrete walls. Ventilation is provided by 10 large air inlets in each longitudinal wall near the base of the module (five on each side) and by 12 large air outlets located slightly below the top of the module (six on each side). The air inlets and outlets are arranged in a series of baffles to avoid direct gamma radiation.

To enhance cooling, the storage cylinders of the MACSTOR module are in direct contact with the air circulating in the module. All surfaces of the storage cylinders are hot galvanized to protect the storage cylinders from ambient air.

The loading operations for the MACSTOR module are identical to those for the concrete canister. Both use the fuel basket, shielded workstation and transfer flask. The only essential difference between the two is the storage structure itself.

Figure B.3: MACSTOR-200 at Gentilly-2

.jpg/object)

B.1.3.4.3 OPG dry storage container

OPG currently operates three spent fuel dry storage facilities, located at the Darlington, Pickering and Western WMFs. OPG dry storage facilities employ DSCs (see figures B.4 and B.5). These are large, transportable containers with an inner cavity for fuel containment. Each one is designed to hold 384 fuel bundles stacked in modules and weighs approximately 60 tonnes when empty, 70 tonnes when loaded.

The containers are rectangular with walls of reinforced, high-density concrete sandwiched between interior and exterior shells made of carbon steel. The inner liner is an integral part of the containment boundary, while the outer liner is intended to enhance structural integrity and facilitate the decontamination of the surface of the DSCs. Helium is used as the inert cover gas in the DSCs cavity to protect the fuel bundles from potential oxidation reactions and to facilitate leak testing of the containment boundary. OPG dry storage facilities are located indoors. There are no anticipated radiological releases under normal operating conditions.

Figure B.4: OPG dry storage container

.jpg/object)

Figure B.5: Dry storage containers at an OPG WMF

.jpg/object)

B.1.3.5 Experiences with dry storage

Research programs have assessed the behaviour of spent fuel when stored in dry and moist air conditions and in a helium environment. The programs have concluded that CANDU fuel bundles, whether intact or with defects, can be stored in DSCs for up to 100 years or more without losing integrity. Additional research is ongoing.

The experience gained at licensed dry storage facilities provides a high level of confidence that CANDU dry storage facilities can be operated safely and without undue risk to workers, the general public and the environment. DSCs have been used successfully and safely at the Pickering WMF since 1996. The safety performance of the facility has been excellent for the entire period. Both the dose rates and emissions from the processing area have remained below regulatory limits.

The thermal and shielding analyses carried out for design and safety assessment purposes have been found to be conservative. Analyses and measurements carried out at the Pickering WMF indicate that the maximum fuel cladding temperature does not exceed 175°C in dry storage. In addition, results of neutron dose rate calculations have demonstrated, as expected, that the dose rates produced by neutrons are negligible compared to those generated by gamma radiation. This result is due to the heavy concrete used as shielding in the DSCs.

To verify the results of the thermal analysis, an experimental thermal performance verification program was carried

out in the summer of 1998. A DSC instrumented with 24 thermocouples at various locations on the inner and outer

liners was loaded with six-year cooled fuel and placed within an array of DSCs containing

10-year cooled fuel. Temperatures were also measured at the interspaces between the DSCs, as were indoor and outdoor

ambient temperatures. The results demonstrated the conservatism of the temperatures predicted analytically.

Similar assessments and measurements were performed on AECL MACSTORs and AECL concrete canisters to confirm and demonstrate the safe storage of spent fuel in these structures.

B.1.3.6 Spent fuel storage facilities

For a description of the spent fuel storage facilities in Canada, see annex 4.

B.1.3.7 Long-term management of spent fuel

Canada does not yet have a long-term WMF for spent fuel. All spent fuel is currently held in interim wet or dry storage at the NPP where it was produced, with the exception of the spent fuel produced at the now-closed NPD facility, which is stored at CRL.

To address the long-term management of spent fuel, the three major waste owners – OPG, H-Q and NB Power – established the Nuclear Waste Management Organization (NWMO) in 2002 under the NFWA.

NWMO is responsible for implementing the Adaptive Phased Management (APM) approach that was selected by the Government of Canada for the long-term management of spent fuel (see sections G.7 and K.2.4). OPG, NB Power, H-Q and AECL are responsible for the management of the spent fuel generated at their respective sites until the NWMO is ready to accept the spent fuel for management in a facility constructed using the APM approach. OPG is also responsible for the interim storage of the spent fuel generated at the Bruce NGSs.

B.1.4 Radioactive waste management practices

The radioactive content of wastes varies with the source; therefore, management techniques depend on the characteristics and volume of the waste.

Certain types of radioactive wastes (such as waste from hospitals, universities and industry) contain only small amounts of radioactive materials with short half-lives, meaning the radioactivity decays within hours or days. After holding the waste until the radioactivity has decayed to acceptable levels as authorized by the CNSC, the waste can be disposed of by conventional means (e.g., in local landfill or sewer systems).

Radioactive waste from hospitals and universities is generally shipped to Chalk River Laboratories (CRL) for management. The storage facilities CRL include shielded above-ground storage buildings, concrete bunkers and concrete tile holes. In some cases, radioactive waste is shipped to waste treatment facilities in the U.S. with the volume-reduced residues returned for storage by the waste owner in Canada.

Canadian methods for the management of radioactive waste are similar to those of other countries. As disposal facilities are not yet available in Canada for radioactive wastes, emphasis is placed primarily on minimization, volume reduction, conditioning and interim or long-term storage of the wastes. Some of the waste may be reduced in volume (for example, by compaction or incineration) prior to storage. All radioactive waste currently generated is stored in such a way that it can be retrieved when necessary.

Operators have instituted methods to recover storage space by cascading waste after sufficient radioactive decay or reclaiming existing storage space through further compaction (super compaction), segregation, or both. As is the case with all nuclear activities, the facilities for handling radioactive waste must be licensed by the CNSC and conform to all pertinent regulations and licence conditions. The waste management objective across the industry, from mines to reactors, is the same: to control and limit the release of potentially harmful substances into the environment.

In keeping with the Government of Canada’s Radioactive Waste Policy Framework, Canada has taken different approaches for managing HLW, ILW, LLW and uranium mine and mill tailings. These different approaches reflect not only the different scientific and technical characteristics of the wastes, but also the economics and the geographic dimensions of Canada and the locations of the wastes. Long-term strategies and solutions for historic LLW are being developed and implemented for the various regions of the country.

For a description of the radioactive WMFs in Canada, see annex 5.

B.1.4.1 Non-fuel high-level radioactive waste

The irradiated fuel bays at the Bruce B NGS store cobalt-60 produced from the harvesting of cobalt adjuster rods at the Bruce B NGS. The cobalt-60 initially produced is sold to Nordion Inc. under an agreement between the two parties, where it is processed and converted into high-strength industrial and medical radiation sources. That agreement provides Nordion with an allowance to send back to the Bruce B NGS as much cobalt-60 as was originally supplied (with certain conditions). A separate agreement between OPG and BP obligates OPG to take title of the spent cobalt that has been received into the Bruce B NGS irradiated fuel bay from Nordion.

B.1.4.2 Low- and intermediate-level radioactive waste

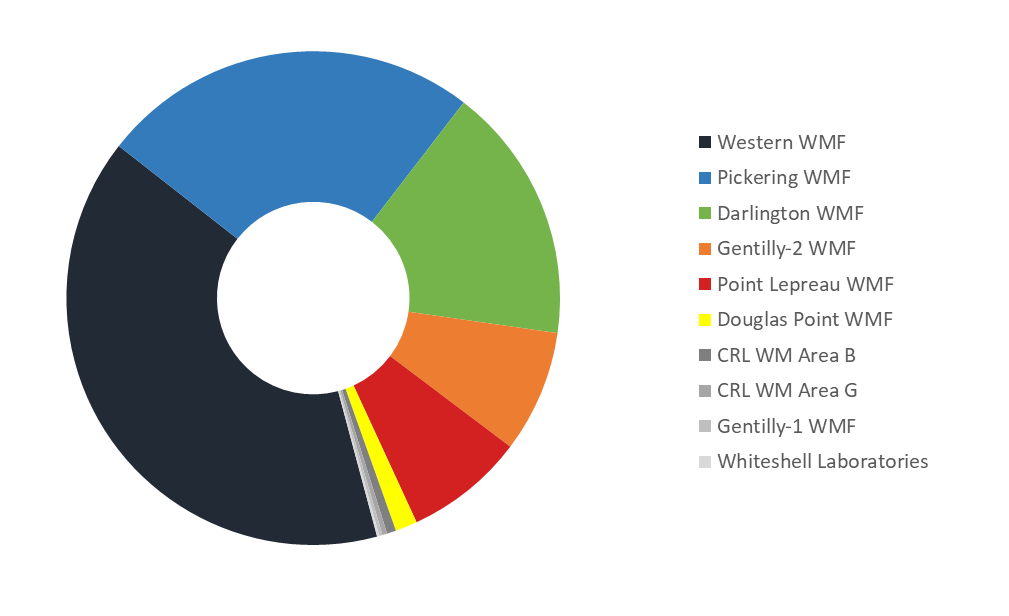

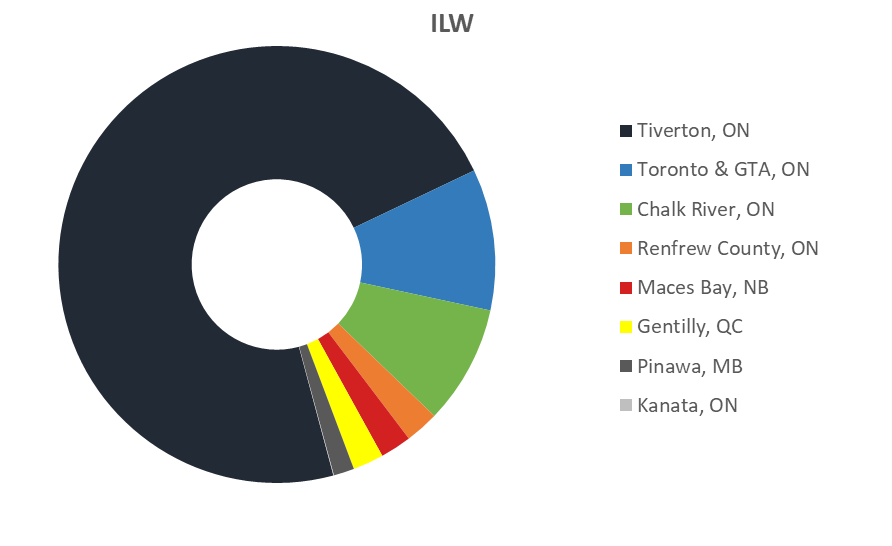

As the waste owners, AECL and OPG (which own 20 of Canada’s 22 CANDU reactors) are responsible for approximately 90 percent and 99 percent, respectively, of the annual accumulated volume of low- and intermediate-level radioactive wastes (L&ILW) as of 2019. These accumulation rates represent the waste generated from research and development activities at CRL (including from decommissioning and environmental remediation) and nuclear power production in Ontario respectively. Included in AECL’s accumulation rate is L&ILW for long-term management from a number of small producers and users of radioactive materials (e.g., hospitals and universities). The other two CANDU reactors (owned by NB Power and H-Q) and Cameco’s uranium processing and conversion facilities in Ontario generate the majority of the remaining waste. In general, the owners of L&ILW are licensed by the CNSC to manage and operate interim storage facilities for their radioactive wastes.

The majority of L&ILW from OPG owned CANDU reactors (including Bruce A and B) is safely stored in a central location at the Western WMF at the Bruce nuclear site in Kincardine, Ontario. Some ILW from unit refurbishments is stored at the Darlington and Pickering reactor sites within their respective WMFs. NB Power and H-Q have their own facilities for the interim storage of L&ILW at their reactor sites.

As described in section K.3.4, activities dealing with legacy radioactive waste and decommissioning liabilities at AECL sites are being advanced by CNL under a government-owned contractor-operated (GoCo) arrangement. For waste from research and development, AECL/CNL have waste storage facilities at two sites – CRL and WL – as well as at its three prototype reactor sites. As decommissioning progresses, L&ILW are to be consolidated at CRL for storage. Operational storage facilities include a bulk materials landfill for de-watered sewage sludge, shielded modular above-ground storage structures, concrete bunkers and tile holes. Additional capacity for LLW storage has been created at CRL while waiting for the NSDF to become operational for the disposal of LLW. This additional capacity is in the form of hard-standing to accept LLW packaged in approved sea containers. On behalf of AECL, CNL also accepts L&ILW from small generators, like those in hospitals, universities and small industries, on a fee-for-service basis.

In addition to existing interim storage facilities at CRL, a key enabling component is the proposed construction of the near surface disposal facility (NSDF) with a total planned disposal capacity of 1 million m3, scheduled to be available by 2024 for the disposal of LLW. Progress and achievements over the last three years are summarized in section K.2.3.2.

Radioactive waste from hospital nuclear medicine departments and from universities and similar facilities contains only small amounts of radioactive materials with short half-lives. The radioactivity of this waste normally decays within hours, days or months. Institutions like hospital nuclear medicine departments and universities have implemented delay-and-decay programs, after which waste can be treated using conventional means.

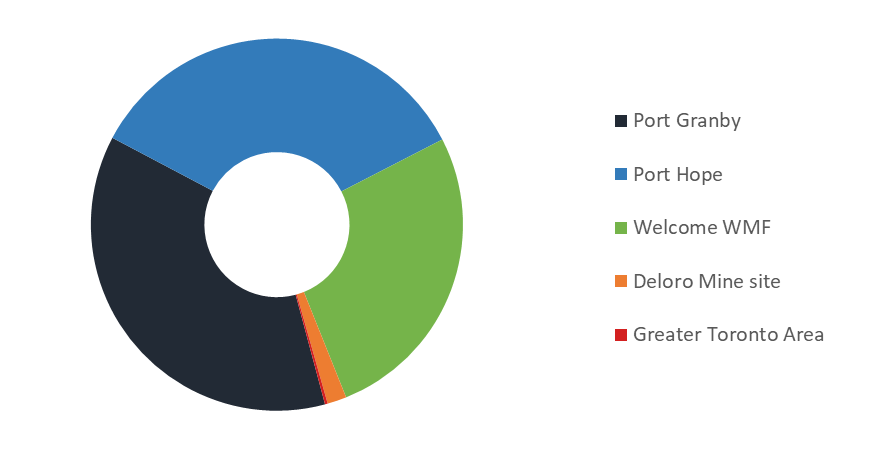

Canada has significant volumes of LLW from past practices (referred to as historic waste) that was once managed in a manner no longer considered acceptable, but for which the current owner cannot be reasonably held responsible. Canada’s historic waste inventory consists largely of refinery process residues in the area of Port Hope, Ontario, and radium- and uranium-contaminated soils in the form of spilled ores on the Northern Transportation Route (NTR) from the former Port Radium mine site in the Northwest Territories. The Government of Canada has accepted responsibility for the long-term management of these wastes.

The bulk of Canada’s historic LLW is located in the southern Ontario communities of Port Hope and Clarington. These wastes and contaminated soils amount to roughly 1.7 million m3 and relate to the historic operations of a radium and uranium refinery in Port Hope dating back to the 1930s. In March 2001, the Government of Canada and the local municipalities agreed on community-developed proposals as potential solutions for the cleanup and long-term management of historic LLW in the Port Hope area, and launched the Port Hope Area Initiative (PHAI). The PHAI and other initiatives that address historic waste are described in section K.3.4 and annex 7.2. These initiatives come under the responsibility of AECL, and the work is delivered by CNL, based on a GoCo model.

Activities continue to be carried out to quantify the extent of historic LLW liabilities across Canada (non-Port Hope sites) and develop plans for their discharge. As part of one key objective, CNL will significantly reduce or eliminate liabilities by 2026 by safely executing remediation projects. This will facilitate the cost-effective long-term management of historic LLW, in keeping with the policy direction provided by AECL.

Legacy wastes (in the Canadian context) specifically date back to the Cold War and birth of nuclear technologies in Canada; these wastes are located at AECL sites. These wastes include existing radioactive wastes and wastes resulting from decommissioning disused buildings and infrastructure, and from environmental remediation.

B.1.4.2.1 Long-term management of low- and intermediate-level radioactive waste

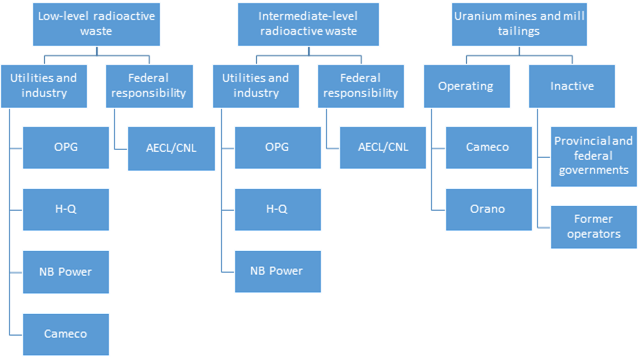

Although numerous government departments, agencies, hospitals, universities and industry members are involved in the management of radioactive waste, only a limited number of organizations are involved in its long-term management. Figure B.6 shows the organizations that are responsible for the long-term management of radioactive waste in Canada.

Figure B.6: Organizations responsible for the long-term management of radioactive waste in Canada

OPG, NB Power and H-Q are responsible for the long-term management of L&ILW generated by nuclear reactor operations. For OPG, this includes L&ILW generated at the Bruce NGSs. In 2020, OPG cancelled its proposed deep geologic repository project at the Bruce site. OPG is moving forward with developing alternate solutions for the permanent disposal of L&ILW.

AECL is responsible for the long-term management of L&ILW at its sites – CRL, WL and three partially decommissioned prototype reactors (Gentilly-1, Douglas Point and the NPD) – as well as for the L&ILW it accepts from other Canadian licensees (mostly originating from hospitals and universities) on a fee-for-service basis. Under a GoCo model, CNL delivers this work on behalf of AECL. For information on the AECL/CNL long-term waste management strategy for L&ILW, see section K.2.3.

AECL is also responsible for the cleanup and safe management of historic LLW at sites across Canada for which the Government of Canada has accepted responsibility. This includes the PHAI and activities associated with the Low-Level Radioactive Waste Management Office. Again, this work is delivered by CNL on behalf of AECL. For additional information see section K.3.4.