Regulatory Oversight Report for Nuclear Processing, Small Research Reactor and Class IB Accelerator Facilities: 2015

Table of Contents

- Executive Summary

- 1 Overview

- Section I: Uranium Processing facilities

- 2 Overview

- 3 Cameco Blind River Refinery

- 4 Port Hope Conversion Facility

- 5 Cameco Fuel Manufacturing Inc

- 6 GE Hitachi Nuclear Energy Canada Inc.

- Section II: Nuclear Substance Processing Facilities

- 7 Overview

- 8 SRB Technologies (Canada) Inc.

- 9 Nordion (Canada) Inc

- 10 Best Theratronics Ltd.

- Section III: Small nuclear research reactor facilities

- 11 Overview

- 12 McMaster University

- 13 SLOWPOKE-2 facilities

- Section IV: Class IB particle accelerator facilities

- 14 Overview

- 15 TRIUMF Accelerators Inc.

- 16 Canadian Light Source Inc.

- Overall conclusions

- Appendix A: Safety and control area framework

- Appendix B: Performance rating definitions

- Appendix C: Safety and control area ratings

- Appendix D: Financial guarantees

- Appendix E: Worker dose data

- Appendix F: Environmental data

- Appendix G: Lost-time injuries

- Appendix H: Links to licensee websites

- Appendix I: Changes to licences and licence conditions handbooks

- Acronyms and abbreviations

- Glossary

Executive Summary

This report presents the operating performance of the uranium and nuclear substance processing facilities, small nuclear research reactor facilities and Class IB particle accelerator facilities regulated by the Canadian Nuclear Safety Commission (CNSC). The information provided in this report covers the 2015 calendar year and, when applicable, shows trends and compares information to previous years.

This is the first year that small nuclear research reactor facilities are included in the reporting cycle. To better align the reporting requirements for CNSC-licensed facilities, this is also the first time that Class IB particle accelerator facilities are reported along with uranium and nuclear substance processing facilities. Previously, Class IB particle accelerator facilities were reported in the Regulatory Oversight Report on the Use of Nuclear Substances in Canada.

This report focuses on three safety and control areas (SCAs): radiation protection, environmental protection, and conventional health and safety. These three SCAs provide a good overall indication of the safety performance for the facilities discussed in this report. This report also highlights a discussion of public information programs, ratings for all 14 SCAs, reportable events, any significant facility modifications and areas of increased regulatory focus.

For 2015, the performance in all 14 SCAs for the facilities was as follows:

- Uranium processing facilities were rated as "satisfactory" or better.

- Nuclear substance processing facilities were rated as "satisfactory" or better with the exception of Best Theratronics Ltd., which received a "below expectations" rating in emergency management and fire protection.

- Small nuclear research reactor facilities were rated as "satisfactory" or better.

- Class IB particle accelerator facilities were rated as "satisfactory" or better with the exception of Canadian Light Source Inc., which received a "below expectations" rating in human performance management.

Through their regulatory oversight activities, CNSC staff confirmed that Canada’s uranium and nuclear substance processing facilities, small nuclear research reactor facilities and Class IB particle accelerator facilities continued to operate safely during 2015, despite the "below expectations" ratings mentioned above. The CNSC’s regulatory oversight activities included onsite inspections, reviews of reports submitted by licensees, and event and incident reviews, supported by follow-up and general communication with the licensees.

CNSC staff concluded that, in 2015, each of the regulated facilities discussed in this report made adequate provision for the health and safety of workers as well as the protection of the public and the environment, and for meeting Canada’s international obligations on the peaceful use of nuclear materials.

1 Overview

1.1 Background

The The Regulatory Oversight Report for Nuclear Processing, Small Research Reactor and Class IB Accelerator Facilities in Canada: 2015 summarizes the Canadian Nuclear Safety Commission (CNSC) staff assessment of the safety performance of the following licensees:

- uranium processing facilities

- Cameco Corporation Blind River Refinery in Blind River, ON

(FFOL-3632.00/2022) - Cameco Corporation Port Hope Conversion Facility in Port Hope, ON

(FFOL-3631.00/2017) - Cameco Fuel Manufacturing Inc. in Port Hope, ON

(FFOL-3641.00/2022) - GE Hitachi Nuclear Energy Canada Inc. in Peterborough, ON

(FFOL-3620.00/2020) - GE Hitachi Nuclear Energy Canada Inc. in Toronto, ON

(FFOL-3620.00/2020)

- Cameco Corporation Blind River Refinery in Blind River, ON

- nuclear substance processing facilities

- SRB Technologies (Canada) Inc. in Pembroke, ON

(NSPFOL-13.00/2022) - Nordion (Canada) Inc. in Ottawa, ON

(NSPFOL-11A.00/2025) - Best Theratronics Ltd. in Ottawa, ON

(NSPFOL-14.01/2019)

- SRB Technologies (Canada) Inc. in Pembroke, ON

- small nuclear research reactor facilities

- McMaster Nuclear Reactor at McMaster University in Hamilton, ON

(NPROL-01.00/2024) - Safe LOW-Power Kritical Experiment (SLOWPOKE-2) facilities located at:

- University of Alberta in Edmonton, AB

(NPROL-18.00/2023) - Saskatchewan Research Council in Saskatoon, SK

(NPROL-19.00/2023) - Royal Military College of Canada in Kingston, ON

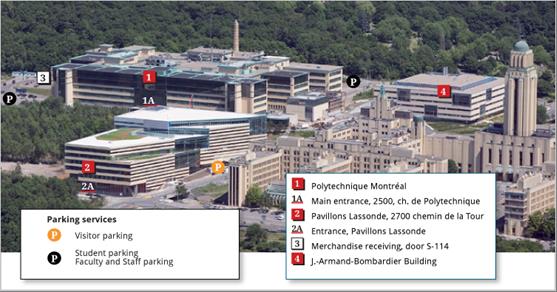

(NPROL-20.00/2023) - École Polytechnique de Montréal in Montréal, QC

(PERFP-9A.01/2023)

- University of Alberta in Edmonton, AB

- subcritical assembly at École Polytechnique de Montréal in Montréal, QC

(PERFP-9A.01/2023)

- McMaster Nuclear Reactor at McMaster University in Hamilton, ON

- Class IB particle accelerator facilities

- TRIUMF Accelerators Inc. in Vancouver, BC

(PAIOL-01.00/2022) - Canadian Light Source Inc. in Saskatoon, SK

(PAIOL-02.01/2022)

- TRIUMF Accelerators Inc. in Vancouver, BC

The assessment aligns with the legal requirements of the Nuclear Safety and Control Act (NSCA) and the regulations made under the NSCA, the conditions of facility licences, and applicable standards and regulatory documents.

The report highlights the areas of regulatory focus for CNSC staff – including information on regulatory requirements and expectations in selected areas – and discusses significant events, licence changes, major developments and overall performance. It provides performance data on the safety and control areas (SCAs) of radiation protection, environmental protection, and conventional health and safety, which provide a good overall indication of the safety performance for the facilities discussed in this report.

The information covers the 2015 calendar year and, where appropriate, compares information to previous years.

1.2 CNSC regulatory efforts

The CNSC regulates the nuclear sector in Canada, including Canada’s uranium and nuclear substance processing facilities, small nuclear research reactors and Class IB particle accelerator facilities, to:

- protect the health, safety and security of Canadians and the environment

- implement Canada’s international commitments on the peaceful use of nuclear energy

- disseminate objective scientific, technical and regulatory information to the public

The CNSC regulates these facilities through licensing, reporting, verification and enforcement activities. For each facility, CNSC staff conduct onsite inspections, assessments, reviews and evaluations of licensee programs, processes and safety performance reports.

CNSC staff establish compliance plans for each facility based on risk-informed regulatory oversight of the facility’s activities. Compliance plans are continuously reviewed to take into consideration events, facility modifications, changes in licensee performance and lessons learned.

Onsite inspections conducted in 2015 covered various aspects of many SCAs. CNSC staff apply a risk-informed approach for compliance activities, commensurate with the risk associated with these facilities. In 2015, CNSC staff conducted 35 onsite inspections at uranium and nuclear substance processing facilities, small nuclear research reactors and Class IB particle accelerator facilities in Canada. A breakdown of the number of inspections is provided in each industry’s respective sections.

While some inspections focus on specific SCAs, CNSC inspectors strive to ensure that aspects of radiation protection, environmental protection, and conventional health and safety are covered in every inspection. This is done to continually ensure:

- radiation protection measures are effective and radiation doses to workers remain as low as reasonably achievable (ALARA), taking into account social and economic factors

- the environmental protection programs are effective and releases remain ALARA

- conventional health and safety programs continue to protect workers from injuries and accidents

CNSC staff also verify compliance through desktop reviews of reports and licensee programs, which are supplemented with meetings, presentations and facility visits.

1.3 Ratings and performance

CNSC staff use the SCA Framework in evaluating each licensee’s safety performance. The framework includes 14 SCAs, each sub-divided into specific areas that define its key components. (See appendix A for a complete list of the SCAs and specific areas used in this report.)

CNSC staff assess licensee performance in each applicable SCA according to the following four ratings:

- fully satisfactory (FS)

- satisfactory (SA)

- below expectations (BE)

- unacceptable (UA)

A full definition of the four ratings is provided in appendix B. Ratings are provided for each applicable SCA. The ratings are derived from the compliance activities that CNSC staff conduct in the various SCAs.

To ensure each licensee is operating safely, CNSC staff apply a risk-informed approach to the compliance oversight of a facility. CNSC staff determine the type and level of review, inspection and testing in a manner that is consistent with the risk posed by the regulated activities. The CNSC recognizes that the level of risk must be considered to ensure resources are appropriately allocated and controls are applied based on the complexity of the facility, the hazards and magnitude of the potential risks associated with the activities at the facility.

A licensee’s performance is measured by the ability to minimize all risks posed by the licensed activity and to comply with all regulatory requirements. Performance in each SCA is continually assessed by CNSC staff. It is important to understand that each SCA is evaluated individually and every facility has different inputs into the annual rating for a specific SCA. For example, a rating may not have an input from onsite inspections if no onsite inspections were conducted in the area during the year. In these cases, CNSC staff rating input is the information provided by the licensees in their annual compliance reports.

The three SCAs focused on this report – radiation protection, environmental protection, and conventional health and safety – have metrics to demonstrate a licensee’s performance, such as the radiation dose to workers and the public, releases to the environment and the number of lost-time injuries.

1.4 CNSC Independent Environmental Monitoring Program

Under the NSCA, the licensee of each nuclear facility is required to develop, implement and maintain an environmental monitoring program to demonstrate that the public and the environment are protected from emissions related to the facility’s licensed activities. The results of these monitoring programs are submitted to the CNSC to ensure compliance with applicable guidelines and limits, as set out in regulations that oversee Canada’s nuclear industry.

The CNSC has implemented its Independent Environmental Monitoring Program (IEMP) to verify that the public and the environment around licensed nuclear facilities are safe. It is a regulatory tool that complements the CNSC’s ongoing compliance verification program. The IEMP involves taking samples from public areas around the facilities, then measuring and analyzing the amount of radiological (nuclear) and hazardous substances in those samples.

In 2015, CNSC staff conducted independent environmental monitoring at the Cameco Port Hope Conversion Facility, Cameco Fuel Manufacturing and SRB Technologies. The 2015 IEMP results, which can be found on the CNSC’s IEMP Web page, indicate that the public and the environment in the vicinity of these facilities are protected and safe, and that there are no adverse environmental or health effects as a result of site operations. These results are consistent with the results submitted by the licensees, demonstrating that their environmental protection programs are protecting the health and safety of people and the environment.

Section I: Uranium processing facilities

2 Overview

This section of the report focuses on the five uranium processing facilities in Canada:

- Cameco Corporation (Cameco) Blind River Refinery (BRR) in Blind River, ON

- Cameco Corporation Port Hope Conversion Facility (PHCF) in Port Hope, ON

- Cameco Fuel Manufacturing Inc. (CFM) in Port Hope, ON

- GE Hitachi Nuclear Energy Canada Inc. (GEH-C) Facility in Peterborough, ON

- GE Hitachi Nuclear Energy Canada Inc. facility in Toronto, ON

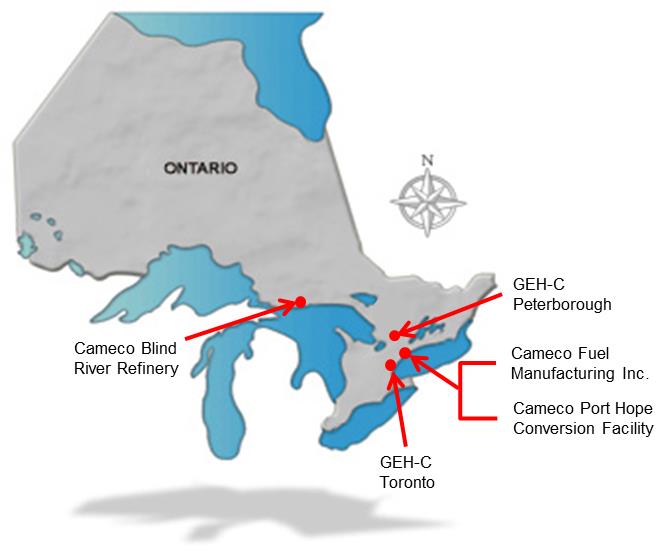

The three Cameco facilities operate under separate operating licences, which were issued in March 2012. The licenses for the BRR and CFM facilities expire in February 2022, while the PHCF licence expires in February 2017. In November 2015, Cameco submitted its application to renew its PHCF operating licence. The licence renewal hearing is scheduled the week of November 9, 2016 in the community of Port Hope, ON. The two GEH-C facilities operate under a combined licence issued in January 2011 that expires in December 2020. All five facilities are located in the province of Ontario, as shown in figure 2-1.

Figure 2-1: Location of uranium processing facilities in Ontario, Canada

Description

Figure 2-1: Location of uranium processing facilities in Ontario, Canada

This map shows the location of the uranium processing facilities in Ontario, Canada: the Cameco Blind River Refinery in Blind River; the GEH-C facilities in Toronto and Peterborough; and the Cameco Port Hope Conversion Facility and Cameco Fuel Manufacturing Inc., both of which are located in Port Hope.

CNSC staff conducted consistent and risk-informed regulatory oversight activities at Canada’s uranium processing facilities in 2015. Table 2-1 presents the licensing and compliance effort for uranium processing facilities during the reporting period.

| Facility | Number of onsite inspections | Person days for compliance | Person days for licensing activities |

|---|---|---|---|

| Blind River Refinery | 3 | 217 | 32 |

| Port Hope Conversion Facility | 5 | 533 | 148 |

| Cameco Fuel Manufacturing | 3 | 237 | 6 |

| GEH-C Toronto and Peterborough | 4 | 282 | 25 |

In 2015, CNSC staff performed 15 onsite inspections at the uranium processing facilities. All the findings resulting from these onsite inspections were provided to the licensees in a detailed inspection report. All regulatory enforcement actions arising from the findings were recorded in the CNSC regulatory information bank to ensure all enforcement actions are tracked to completion.

Each uranium processing facility licensee is required, per their operating licences, to submit an annual compliance report by March 31. These reports contain facility performance information such as annual production volumes, improvements to programs in all safety and control areas (SCAs) and details related to environmental, radiological and safety performance, including any events and associated corrective actions.

CNSC staff review these reports as part of normal regulatory compliance oversight to verify that licensees are complying with their regulatory requirements and are operating safely. The full versions of these reports are available on the licensees’ websites, as provided in appendix H.

The SCA performance ratings of uranium processing facilities are presented in table 2-2. For 2015, CNSC staff ratings for all individual SCAs were "satisfactory" for the uranium processing facilities, except for Blind River Refinery, which was given a "fully satisfactory" rating in the conventional health and safety SCA. Appendix C contains the SCA ratings from 2011 to 2015 for each facility.

| Safety and control area | Blind River Refinery | Port Hope Conversion Facility | Cameco Fuel Manufacturing | GEH-C Toronto and Peterborough |

|---|---|---|---|---|

| Management system | SA | SA | SA | SA |

| Human performance management | SA | SA | SA | SA |

| Operating performance | SA | SA | SA | SA |

| Safety analysis | SA | SA | SA | SA |

| Physical design | SA | SA | SA | SA |

| Fitness for service | SA | SA | SA | SA |

| Radiation protection | SA | SA | SA | SA |

| Conventional health and safety | FS | SA | SA | SA |

| Environmental protection | SA | SA | SA | FS |

| Emergency management and fire protection | SA | SA | SA | SA |

| Waste management | SA | SA | SA | SA |

| Security | SA | SA | SA | SA |

| Safeguards and non-proliferation | SA | SA | SA | SA |

| Packaging and transport | SA | SA | SA | SA |

Each facility is required to develop decommissioning plans, which are reviewed and approved by CNSC staff. Each plan is accompanied by a financial guarantee that provides the funding necessary to complete the decommissioning work. The financial guarantees for each facility are listed in appendix D.

2.1 Radiation protection

This SCA covers the implementation of a radiation protection program in accordance with the Radiation Protection Regulations. The program must ensure contamination levels and radiation doses received by individuals are monitored, controlled and maintained as low as reasonably achievable (ALARA).

This SCA encompasses the following specific areas:

- application of ALARA

- worker dose control

- radiation protection program performance

- radiological hazard control

- estimated dose to the public

The 2015 rating for the radiation protection SCA for all uranium processing facility licensees was "satisfactory," unchanged from the previous year.

Ratings for radiation protection SCA, uranium processing facilities, 2015

| Blind River Refinery | Port Hope Conversion Facility | Cameco Fuel Manufacturing Inc | GEH-C Toronto and Peterborough |

|---|---|---|---|

| SA | SA | SA | SA |

Application of ALARA

During 2015, all uranium processing facility licensees continued to implement radiation protection measures to keep radiation exposures and doses to persons ALARA, taking into account social and economic factors. The CNSC requirement to apply the ALARA principle has consistently resulted in doses to persons to be well below regulatory dose limits.

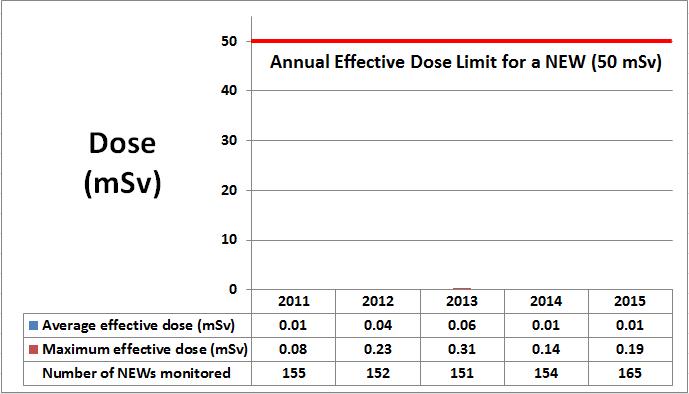

Worker dose control

The design of radiation protection programs, including the dosimetry methods and the determination of workers who are identified as nuclear energy workers (NEWs), varies depending on the radiological hazards present and the expected magnitude of doses received by workers. Taking into consideration the inherent differences in the design of radiation protection programs between licensees, the dose statistics provided in this report are primarily for NEWs. Additional information is provided in the facility-specific write-ups on the total number of monitored persons, including workers, contractors and visitors.

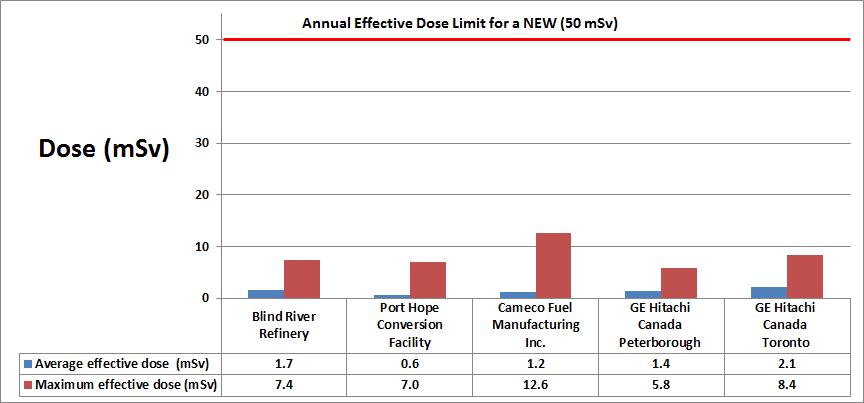

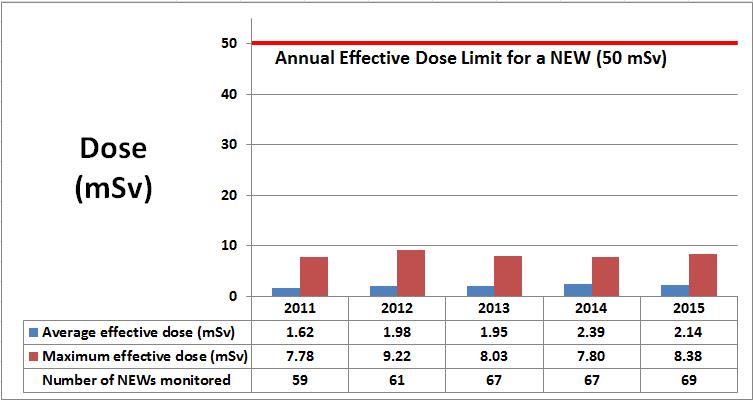

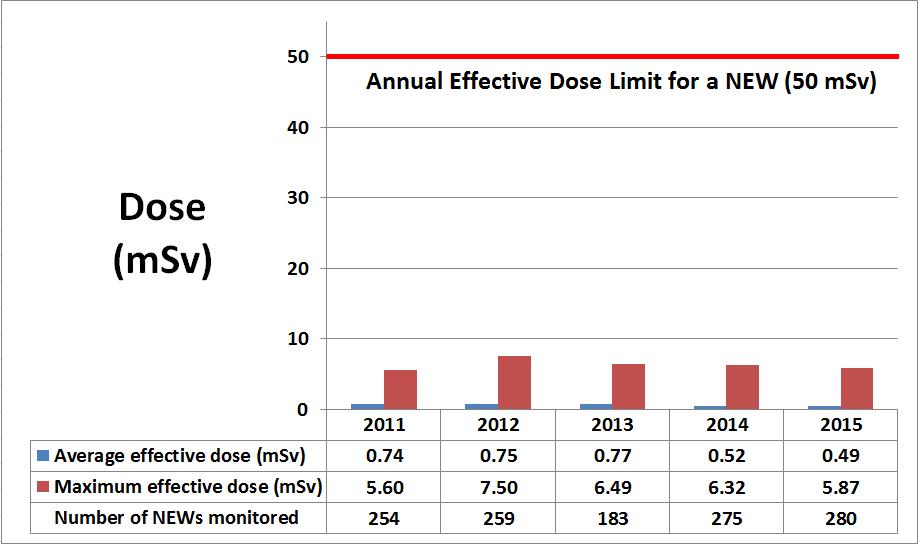

The maximum and average effective doses for NEWs at uranium processing facilities are provided in figure 2-2. In 2015, the maximum individual effective dose received by a NEW at all facilities ranged from 5.8 millisieverts (mSv) to 12.6 mSv, which is well below the regulatory dose limit of 50 mSv/year for a NEW.

Description

| Blind River Refinery Facility | Port Hope Conversion Facility | Cameco Fuel Manufacturing Inc. | GE Hitachi Canada Peterborough | GE Hitachi Canada Toronto | |

|---|---|---|---|---|---|

| Average effective dose (mSv/yr) | 1.7 | 0.6 | 1.2 | 1.4 | 2.1 |

| Maximum effective dose (mSv/yr) | 7.4 | 7.0 | 12.6 | 5.8 | 8.4 |

During 2015, all uranium processing facility licensees monitored and controlled the radiation exposures and doses received by all persons present at their licensed facilities, including workers, contractors and visitors. Radiological hazards in the uranium processing facilities vary due to the complex and differing work environments. Therefore, direct comparison of doses received by NEWs between facilities does not necessarily provide an appropriate measure of how effective the licensee is in implementing its radiation protection program.

Radiation protection program performance

CNSC staff conducted regulatory oversight activities at all uranium processing facilities during 2015 to verify compliance of the licensees’ radiation protection programs with regulatory requirements. This regulatory oversight consisted of desktop reviews and radiation protection-specific compliance verification activities, including onsite inspections. Through these oversight activities, CNSC staff confirmed that all uranium processing facilities have effectively implemented their radiation protection programs to control occupational exposures to workers.

Action levels for radiological exposures are established as part of the licensees’ radiation protection programs. Licensees are responsible for identifying the parameters of their program that represent timely indicators of potential losses of control of the program. For this reason, action levels are licensee-specific and may change over time depending on operational and radiological conditions. If an action level is reached, it triggers the licensee to establish the cause, notify the CNSC and, if applicable, restore the effectiveness of the program. It is important to note that occasional exceedances indicate that the action level chosen is likely an adequately sensitive indicator of a potential loss of control of the radiation protection program. Action levels that are never exceeded may not be sensitive enough to detect the emergence of a potential loss of control. For this reason, licensee performance is not judged solely on the number of action level exceedances in a given period but rather how the licensee responds and identifies corrective actions to enhance program performance and prevent reoccurrence. In 2015, there were a total of four radiological action level exceedances across all uranium processing facility licensees. In all instances, the exceedances were reported to the CNSC, investigated and corrective actions established to the satisfaction of CNSC staff.

Radiological hazard control

All uranium processing facility licensees continued to implement adequate measures to monitor and control radiological hazards in their facilities. These measures include delineation of zones for contamination control purposes and in-plant air-monitoring systems. All uranium processing facility licensees continued to implement their workplace monitoring programs to protect workers and have demonstrated that, in 2015, levels of radioactive contamination were controlled within their facilities.

Estimated dose to the public

The maximum dose to the public from licensed activities at each uranium processing facility is calculated using monitoring results from air emissions, liquid effluent releases and fence-line gamma monitoring. The CNSC’s requirements to apply ALARA principles ensure that licensees monitor their facilities and take corrective actions whenever action levels are exceeded.

Table 2-3 provides a comparison of estimated public doses from 2011 to 2015 for the uranium processing facility licensees. Estimated doses to the public from all uranium processing facility licensees continued to be well below the regulatory annual public dose limit of 1 mSv/year.

| Facility | Year | Regulatory limit | ||||

|---|---|---|---|---|---|---|

| 2011 | 2012 | 2013 | 2014 | 2015 | ||

*GEH-C did not report public dose results prior to 2012. The values reported here are based on CNSC staff calculations of GEH-C emissions for the derived release limits (DRL). **Beginning in 2014, GEH-C Toronto implemented environmental gamma-exposure monitoring using licensed dosimeters and began to include this result in its estimated annual public dose. | ||||||

| Blind River Refinery | 0.006 | 0.012 | 0.012 | 0.005 | 0.005 | 1 mSv/yr |

| Port Hope Conversion Facility | 0.019 | 0.029 | 0.021 | 0.012 | 0.006 | |

| Cameco Fuel Manufacturing | 0.042 | 0.031 | 0.013 | 0.018 | 0.025 | |

| GEH-C Toronto | 0.0008 | 0.0011 | 0.0006 | **0.0055 | 0.010 | |

| GEH-C Peterborough | *<0.00001 | <0.001 | <0.001 | <0.001 | <0.001 | |

The uranium processing facility licensees effectively implemented and maintained their radiation protection programs during 2015 to ensure the health and safety of persons working in their facilities.

2.2 Environmental protection

This SCA covers programs that identify, control and monitor all releases of radioactive and hazardous substances and the effects on the environment from facilities or as a result of licensed activities.

It encompasses the following specific areas:

- effluent and emissions control (releases)

- environmental management system

- assessment and monitoring

- protection of the public

- environmental risk assessment

The 2015 rating for the environmental protection SCA for all uranium processing facility licensees was "satisfactory."

Ratings for environmental protection SCA, uranium processing facilities, 2015

| Blind River Refinery | Port Hope Conversion Facility | Cameco Fuel Manufacturing Inc | GEH-C Toronto and Peterborough |

|---|---|---|---|

| SA | SA | SA | SA |

The uranium processing facilities are also regulated by Ontario’s Ministry of the Environment and Climate Change (MOECC). Environmental protection is, therefore, a shared federal and provincial responsibility. The CNSC avoids or minimizes any duplication of regulatory oversight, including MOECC’s requirements, by working cooperatively and inclusively whenever possible.

State of receiving environment

Uranium in ambient air

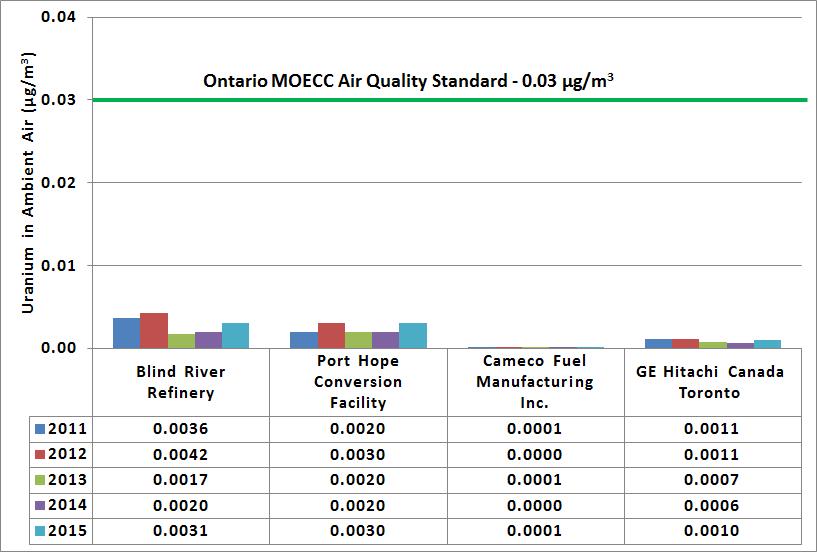

All the uranium processing licensees, except GEH-C Peterborough, operate high-volume air samplers at the perimeter of their facilities to confirm the effectiveness of emission abatement systems and to monitor the impact of uranium emissions on the environment. GEH-C Peterborough does not use fence-line air samplers, as stack emissions at the point of release already meet MOECC air standard for uranium.

The results from high-volume air samplers with the highest values near a facility (maximum annual average) for 2011 through 2015 are provided in figure 2-3. These values are measured as total suspended particulate representing the total amount of uranium in air.

As shown in figure 2-3, the maximum annual average concentration of uranium in ambient air is below the MOECC air standard for uranium (0.03 µg/m3). This new standard for uranium takes effect in 2016.

Description

| Blind River Refinery | Port Hope Conversion Facility | Cameco Fuel Manufacturing Inc. | GE Hitachi Canada Toronto | ||

|---|---|---|---|---|---|

Note: The maximum annual average concentration for BRR in 2012 was 0.0042 µg/m3, previously reported as 0.0030 µg/m3. This is a correction to the results reported in Regulatory Oversight Report for Uranium and Nuclear Substance Processing Facilities in Canada: 2014. | |||||

| 2011 | 0.0036 | 0.0020 | 0.0001 | 0.0011 | |

| 2012 | 0.0042 | 0.0030 | 0.0000 | 0.0011 | |

| 2013 | 0.0017 | 0.0020 | 0.0001 | 0.0007 | |

| 2014 | 0.0020 | 0.0020 | 0.0000 | 0.0006 | |

| 2015 | 0.0031 | 0.0030 | 0.0001/td> | 0.0010 | |

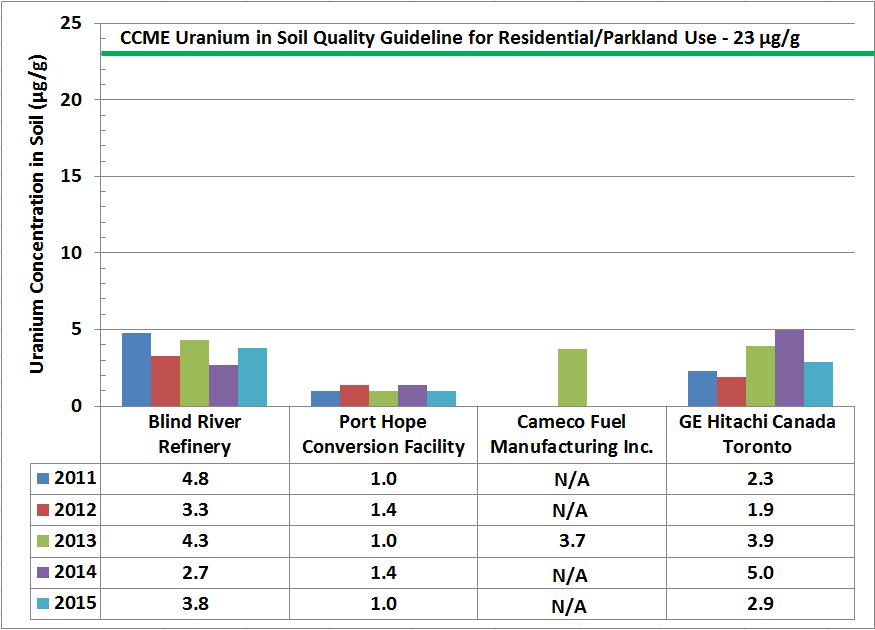

Uranium in soil

The three Cameco facilities and GEH-C Toronto have soil monitoring programs. Uranium releases from the GEH-C Peterborough facility are negligible because the fuel pellets received from the Toronto facility are in solid form and uranium releases to air are very low. This is confirmed by monitoring in the stack; as such, uranium-in-soil monitoring is not warranted at GEH-C Peterborough.

Soil monitoring programs are intended to monitor the long-term effects of air emissions to show whether there is accumulation of uranium in soil in the vicinity of the facility. Soil sampling results in 2015 continue to indicate that current uranium emissions from the uranium processing facilities have no measurable impacts on soil.

Figure 2-4 provides the annual average uranium concentrations in soil results for 2011 through 2015. In Ontario, natural background levels of uranium in soil are generally below 2.5 µg/g. The annual average concentrations of uranium in soil are similar to natural background levels and well below the applicable guideline value for the land-use type, as described by the Canadian Council of Ministers of the Environment (CCME) soil quality guideline for residential and parkland use, which is 23 µg/g.

Description

| Blind River Refinery | Port Hope Conversion Facility | Cameco Fuel Manufacturing Inc. | GE Hitachi Canada Toronto | |

|---|---|---|---|---|

| 2011 | 4.8 | 1.0 | N/A | 2.3 |

| 2012 | 3.3 | 1.4 | N/A | 1.9 |

| 2013 | 4.3 | 1.0 | 3.7 | 3.9 |

| 2014 | 2.7 | 1.4 | N/A | 5.0 |

| 2015 | 3.8 | 1.0 | N/A | 2.9 |

Uranium in the soil at CFM is a result of historic uranium contamination, which is common to the Port Hope area. The sampling frequency at CFM is every three years. The next soil sampling for CFM is scheduled for 2016 and the results will be provided in the next issue of this report.

The uranium processing facility licensees implemented their environmental protection programs satisfactorily during 2015, and their programs are effective in protecting the health and safety of persons working in their facilities.

2.3 Conventional health and safety

This SCA covers the implementation of a program to manage workplace safety hazards and to protect personnel and equipment.

It encompasses the following specific areas:

- performance

- practices

- awareness

The 2015 rating for the conventional health and safety SCA for all uranium processing facility licensees in 2015 was "satisfactory," except for Blind River Refinery, which was given a "fully satisfactory" rating. This is unchanged from the previous year.

Ratings for conventional health and safety SCA, uranium processing facilities, 2015

| Blind River Refinery | Port Hope Conversion Facility | Cameco Fuel Manufacturing Inc | GEH-C Toronto and Peterborough |

|---|---|---|---|

| FS | SA | SA | SA |

Each licensee is responsible for developing and implementing a conventional health and safety program for the protection of its staff and contract workers, which must comply with Part II of the Canada Labour Code.

The regulation of conventional health and safety at uranium processing facilities involves both Employment and Social Development Canada (ESDC) and the CNSC. CNSC staff monitor compliance with regulatory reporting requirements. When a concern is identified, ESDC staff are consulted and asked to take appropriate action. Licensees submit hazardous occurrence investigation reports to both ESDC and the CNSC, in accordance with their respective reporting requirements.

As summarized in table 2-4, the number of recordable lost-time injuries (LTIs) reported by all facilities has remained low from 2011 to 2015. Further information is provided in facility-specific sections as well as appendix G.

| Facility | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|

| Blind River Refinery | 0 | 0 | 0 | 0 | 0 |

| Port Hope Conversion Facility | 3 | 1 | 0 | 1 | 2 |

| Cameco Fuel Manufacturing | 2 | 0 | 0 | 0 | 1 |

| GEH-C Toronto and Peterborough | 0 | 1 | 0 | 1 | 0 |

The uranium processing facility licensees implemented their conventional health and safety programs satisfactorily during 2015, and their programs are effective in protecting the health and safety of persons working in their facilities.

2.4 Public information and disclosure programs

Uranium processing facilities are required to maintain and implement public information and disclosure programs per RD/GD-99.3, Public Information and Disclosure. These programs are supported by disclosure protocols that outline the type of information on the facility and its activities to be shared with the public (e.g., incidents, major changes to operations, periodic environmental performance reports) and how that information will be shared. This ensures timely information about the health, safety and security of persons and the environment and other issues associated with the lifecycle of nuclear facilities are effectively communicated.

In 2015, CNSC staff evaluated licensees’ implementation of their public information and disclosure programs and determined that all licensees were in compliance with RD/GD-99.3 by providing information on the status of their facilities through numerous activities. CNSC staff reviewed the communications activities during this period and noted that licensees used a variety of methods to share information with the public, including regular updates to elected officials, public information sessions, facility tours, participation in community events, newsletters, and ongoing website and social media updates. Licensees also issued information in accordance with their public disclosure protocols.

The uranium processing facility licensees implemented their public information and disclosure programs satisfactorily during 2015, and their programs are effective at communicating information about the health, safety and security of persons and the environment and other issues associated with their facilities.

3 Cameco Blind River Refinery

Cameco owns and operates a Class IB nuclear fuel facility in Blind River, ON, under an operating licence that expires in February 2022. The Blind River Refinery (BRR) is located about five kilometers west of the town of Blind River, as shown in figure 3-1. The Mississauga First Nation (MFN) is the closest community to BRR, located approximately one kilometer from the facility.

Figure 3-1: Aerial view of the Cameco Blind River Refinery

.jpg/object)

BRR refines uranium concentrates (yellowcake) received from uranium mines worldwide to produce uranium trioxide (UO3), an intermediate product of the nuclear fuel cycle. The primary recipient of the UO3 product is Cameco’s Port Hope Conversion Facility (PHCF). Figure 3-2 shows shipping totes that are used to transfer UO3 from BRR to the PHCF.

In 2015, there were no licence amendments to BRR; however, there was one revision to the BRR licence conditions handbook, as described in table I-2, appendix I.

Figure 3-2: Shipping totes used to transfer UO3 from Blind River Refinery to the Port Hope Conversion Facility

3.1 Performance

For 2015, CNSC staff rated BRR’s performance as "satisfactory" in all SCAs except conventional health and safety, which was rated as "fully satisfactory." The BRR facility ratings from 2011 to 2015 are provided in table C-1, appendix C.

In 2015, CNSC staff conducted three onsite inspections at BRR to ensure compliance with the Nuclear Safety and Control Act (NSCA) and its regulations, Cameco’s operating licence and the programs used to meet regulatory requirements. The inspections focused on the management system, emergency management, waste management, radiation protection, environmental protection, and conventional health and safety SCAs. None of the findings from these inspections presented an immediate risk to the health, safety and security of workers, Canadians or the environment.

In 2015, there were no major modifications to the BRR facility that required Commission approval. BRR made improvements to the site by constructing a berm around the facility for flood protection. The berm was designed to mitigate the impact of a flood caused by severe weather. The flood scenario was identified following Cameco’s Fukushima defence-in-depth review against external hazards, severe accident scenarios and emergency preparedness procedures.

There were no action level exceedances involving radiation protection or environmental protection in 2015. There was one radiation protection-related incident reported to the CNSC per the Cameco BRR radiation protection program requirements. Details are provided in section 3.2 under the "Radiation protection program performance" heading.

On October 6, 2015, CNSC staff met with the MFN Lands and Resource Committee as well as MFN staff and community elders. CNSC staff gave a presentation that included information on BRR’s operational performance for 2014 and the facility’s results from the 2013 and 2014 IEMP. Many questions were asked during this meeting, particularly regarding the IEMP results, how the IEMP sampling locations were determined and the possibility of MFN participating in future IEMP sampling campaigns.

On request, CNSC staff held a meeting with MFN on February 2, 2016 to discuss MFN’s current air quality sampling program and its capabilities for interpreting the program’s results, MFN’s concerns regarding sampling locations and the changes to Ontario’s ambient air quality standard for uranium. Following the meeting, CNSC staff and MFN discussed ideas for future sampling campaigns that would include MFN’s traditional lands, and committed to continuing the dialogue and exploring opportunities with MFN to inform the sampling campaign and increase MFN’s understanding of the results.

CNSC’s Participant Funding Program provided financial support to MFN for all meetings mentioned above.

3.2 Radiation protection

Overall compliance ratings for radiation protection SCA, Blind River Refinery, 2011–15

| 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|

| SA | SA | SA | SA | SA |

| For 2015, CNSC staff continued to rate the radiation protection SCA at Cameco’s BRR as "satisfactory." Cameco has implemented and maintained a radiation protection program as required by the Radiation Protection Regulations. | ||||

Application of ALARA

Annually, Cameco establishes radiation protection objectives and targets at BRR with the goal to reduce worker doses and in-plant uranium-in-air concentrations, as examples. A separate ALARA committee is also in place at BRR, which meets regularly to review and discuss issues related to radiation protection and to make recommendations for improving radiation protection at the facility. In 2015, Cameco completed all radiation safety objectives established for the year, including a review to identify opportunities for improving the respiratory protection program for workers.

Worker dose control

Radiation exposures are monitored to ensure compliance with the CNSC’s regulatory dose limits and to maintain radiation doses ALARA. In 2015, no worker’s radiation exposure reported by BRR exceeded the CNSC’s regulatory dose limits.

Cameco ascertains external doses using whole body and extremity dosimetry. For internal radiological exposures, Cameco’s Fuel Services Division holds a CNSC dosimetry service licence, which authorizes Cameco to provide in-house internal dosimetry services at BRR. Internal dose is assessed and assigned at BRR through two programs: urine analysis and lung counting.

At BRR, all Cameco employees are identified as NEWs. Contractors at BRR may also be identified as NEWs if the nature of their work activities and time spent onsite presents a reasonable probability of them receiving an occupational dose greater than 1 mSv. In 2015, total effective dose was assessed for 155 NEWs at BRR, consisting of 142 Cameco employees and 13 contractors. The maximum effective dose received by a NEW in 2015 was 7.4 mSv, or approximately 15 percent of the regulatory effective dose limit of 50 mSv in a one-year dosimetry period. For the five-year dosimetry period from 2011–2015, the maximum individual effective dose to a NEW at BRR was 41 mSv. This radiation dose result represents approximately 41 percent of the regulatory dose limit of 100 mSv per five-year dosimetry period.

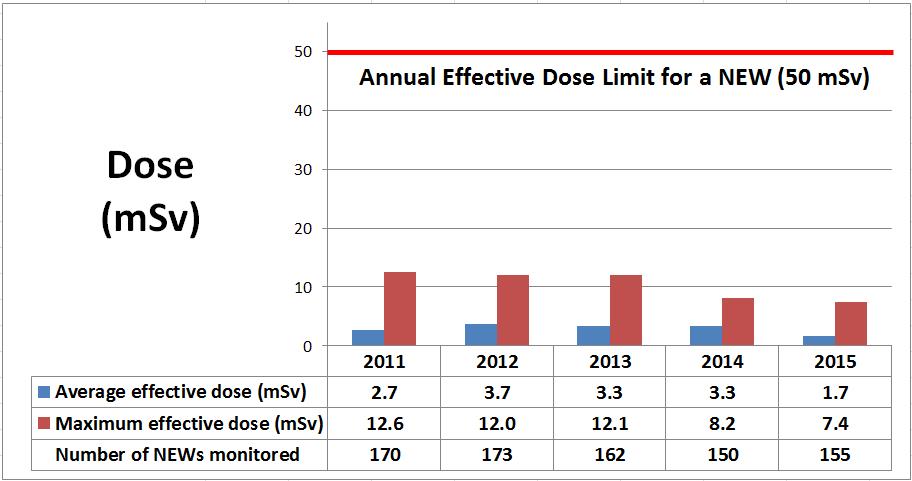

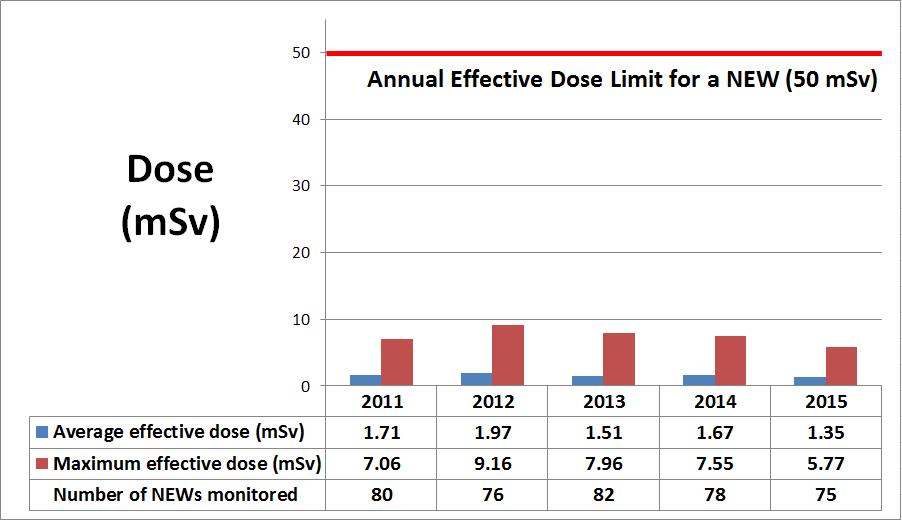

Figure 3-3 provides the average and maximum effective doses to NEWs at BRR between 2011 and 2015.

Description

| 2011 | 2012 | 2013 | 2014 | 2015 | |

|---|---|---|---|---|---|

| Average effective dose (mSv) | 2.7 | 3.7 | 3.3 | 3.3 | 1.7 |

| Maximum effective dose (mSv) | 12.6 | 12.0 | 12.1 | 8.2 | 7.4 |

| Number of NEWs momtored | 170 | 173 | 162 | 150 | 155 |

The average and maximum effective doses at BRR were relatively stable between 2011 and 2015, with a decreasing trend emerging in 2015, likely due to the decrease in UO3 production compared to previous years.

Annual average and maximum equivalent (extremity) and equivalent (skin) dose results from 2011 to 2015 are provided in tables E-7 and E-15 in appendix E. In 2015, the maximum skin dose received by a NEW at BRR was 28.1 mSv, which is approximately six percent of the regulatory equivalent dose limit of 500 mSv in a one-year dosimetry period. The maximum extremity dose received by a NEW at BRR was 15.3 mSv, which is approximately three percent of the regulatory equivalent dose limit of 500 mSv in a one-year dosimetry period. The average and maximum equivalent doses at BRR were relatively stable between 2011 and 2015, with a decreasing trend emerging in 2015, again likely due to the decrease in UO3 production compared to previous years.

Site visitors and non-NEW contractors’ doses are monitored at BRR using whole body dosimetry. In 2015, the maximum effective dose for a non-NEW was 0.1 mSv and averaged less than 0.1 mSv, which is well below the annual regulatory dose limit of 1 mSv.

Radiation protection program performance

CNSC staff assessed the performance of BRR’s radiation protection program in 2015 through various compliance activities. Cameco’s compliance with the Radiation Protection Regulations and CNSC licence requirements at BRR was acceptable. In addition, action levels for radiological exposures have been established as part of the Cameco BRR radiation protection program. If an action level is reached, it triggers Cameco staff to establish the cause, notify the CNSC and, if applicable, restore the effectiveness of the radiation protection program. In 2015, no radiological action levels were reached at BRR.

In 2015, one radiation protection-related incident was reported to the CNSC per the Cameco BRR radiation protection program requirements. In February 2015, four Cameco workers received uranium intakes while performing a work activity; this was caused by deficiencies in work planning, communication and administrative controls, coupled with complacency toward the radiological hazards posed by uranium dust. The work activity was conducted in the calcination area baghouse, which contains uranium concentrates from the front end of the BRR circuit – specifically, uranium concentrates (yellowcake) received from suppliers for processing into UO3. The baghouse is an air-collection device that contains 252 Nomex® filter bags that collect and filter the uranium concentrate dust from the dust-collection system, allowing clean air to exhaust out the dust-collection exhaust vent. Over time, these filter bags must be replaced due to dust loading. As a result of this particular work, four of 11 workers involved in performing the baghouse filter replacement received uranium intakes, necessitating dose assessments and the temporary placement of these workers on restricted status. The maximum internal dose assigned to a worker as a result of this incident was 3.7 mSv. Cameco carried out an investigation into the incident that included a root-cause analysis.

Cameco identified a number of corrective actions, including mandating the use of powered air-purifying respirators by workers when performing this task, along with other improvements to work practices and procedures. In March 2016, CNSC staff performed a radiation protection-focused onsite inspection at BRR, which included extensive follow-up on the implementation of these corrective actions. CNSC staff confirmed that Cameco has effectively implemented measures that improved the radiation protection of workers during the conduct of similar work activities.

Radiological hazard control

Radiation and contamination control programs are established at BRR per regulatory requirements to control and minimize radiological hazards and the spread of radioactive contamination. Methods of control include radiological zone controls and monitoring to confirm the effectiveness of the program. BRR staff conducted in-plant air monitoring, contamination monitoring and radiation dose rate surveys in 2015, and did not identify any adverse trends. This is consistent with expected radiological conditions within the facility.

Estimated dose to the public

The 2011 to 2015 maximum effective doses to a member of the public are shown in table 3-1. Dose to the public remains well below the CNSC regulatory dose limit of 1 mSv/year.

| Dose data | 2011 | 2012 | 2013 | 2014 | 2015 | Regulatory limit |

|---|---|---|---|---|---|---|

| Maximum effective dose (mSv) | 0.006 | 0.012 | 0.012 | 0.005 | 0.005 | 1 mSv/year |

3.3 Environmental protection

| 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|

| SA | SA | SA | SA | SA |

| For 2015, CNSC staff continued to rate the environmental protection SCA at Cameco’s BRR as "satisfactory." Uranium releases to the environment continue to be effectively controlled and monitored in compliance with the conditions of the operating licence and regulatory requirements. The releases of hazardous substances from the facility to the environment are controlled in accordance with the Ontario MOECC’s applicable regulations and Environmental Compliance Approvals. All the releases to the environment were well below regulatory limits during 2015. Groundwater monitoring, surface water monitoring, soil sampling and ambient air data indicate that the public and the environment continue to be protected from facility releases. | ||||

Effluent and emissions control (releases)

To control the release of radioactive and hazardous substances into the environment, CNSC licensees are required to develop and implement policies, programs and procedures that comply with all applicable federal and provincial environmental protection regulations. Licensees are also required to have suitably trained and qualified staff to effectively develop, implement and maintain their environmental protection programs.

Atmospheric Emissions

Cameco monitors uranium, nitrogen oxides (NOx) and particulates released from the BRR stacks on a daily basis. The monitoring data in table 3-2 demonstrate that stack emissions from the facility in 2015 continued to be effectively controlled as they were consistently well below their respective licence limits. No action levels were exceeded at any time in 2015.

| Parameter | 2011 | 2012 | 2013 | 2014 | 2015 | Licence limit |

|---|---|---|---|---|---|---|

Note: results less than detection limit are denoted with the "<" symbol | ||||||

| Dust collection and exhaust ventilation stack – uranium (kg/h) | 0.00010 | 0.00006 | 0.00004 | 0.00005 | 0.00005 | 0.1 |

| Absorber stack – uranium (kg/h) | <0.00001 | <0.00001 | <0.00001 | <0.00001 | <0.00001 | 0.1 |

| Incinerator stack – uranium (kg/h) | <0.00001 | <0.00001 | <0.00001 | <0.00001 | <0.00001 | 0.01 |

| Absorber stack: nitrogen oxides (NOx) + nitric acid (HNO3) (kg NO2/h) | 3.9 | 3.3 | 3.4 | 2.0 | 2.5 | 56.0 |

| Particulate (kg/h) | 0.027 | 0.024 | 0.014 | 0.009 | 0.006/td> | 11.0 |

Liquid effluent

There are three sources of allowable liquid effluent from the BRR facility: plant effluent, stormwater runoff and sewage treatment plant effluent. These effluents are collected in lagoons and treated, as required, prior to being discharged into Lake Huron. Cameco monitors uranium, radium-226, nitrates and pH in liquid effluents to demonstrate compliance with their respective licensed limits. The average monitoring results from 2011 to 2015 are summarized in table 3-3. For 2015, the liquid discharges from the facility continued to be below their respective licensed limits. No action levels were exceeded at any time in 2015.

| Parameter | 2011 | 2012 | 2013 | 2014 | 2015 | Licence limit |

|---|---|---|---|---|---|---|

Note: Results less than detection limit are denoted as “<”. | ||||||

| Uranium (mg/l) | 0.02 | 0.01 | 0.01 | 0.02 | 0.02 | 2 |

| Nitrates (mg/l) | 30 | 28 | 26 | 17 | 13 | 1,000 |

| Radium-226 (Bq/l) | <0.01 | <0.01 | 0.01 | 0.01 | <0.01 | 11 |

| pH (min) | 7.1 | 7.2 | 7.1 | 7.1/td> | 7.2 | 6.0 |

| pH (max) | 8.2 | 8.2 | 8.4 | 8.4/td> | 8.4 | 9.5 |

Environmental management system

Cameco has developed and maintains an environmental management system (EMS) that provides a framework for integrated activities with respect to the protection of the environment at the BRR facility. The EMS, which is described in Cameco’s Environmental Management Program Manual, includes activities such as establishing annual environmental objectives and targets that are reviewed by CNSC staff through compliance verification activities. Cameco holds an annual safety meeting in which environmental protection issues are discussed. CNSC staff, as part of their compliance verification activities, review these minutes and follow up with BRR staff on any outstanding issues. The results of this review demonstrate that Cameco is conducting an annual management review in accordance with CNSC requirements and identified issues are being addressed.

Assessment and monitoring

Cameco’s environmental monitoring programs serve to demonstrate that emissions of nuclear and hazardous materials from BRR are properly controlled. The program also provides data for estimates of annual radiological dose to the public to make sure the public dose attributable to BRR’s operations is ALARA and well below the annual regulatory dose limit of 1 mSv. The principal monitoring activities are focused on monitoring the air, groundwater, surface water, soil and gamma radiation around the facility.

Uranium in ambient air

The concentrations of uranium in the ambient air as monitored by Cameco’s sampling network around the BRR facility continue to be consistently low. In 2015, the highest annual average concentration (among the sampling stations) of uranium in ambient air measured was 0.0031 µg/m3, which is well below the MOECC’s standard for uranium in ambient air of 0.03 µg/m3.

Groundwater monitoring

A total of 43 monitoring wells currently exist in and around the BRR facility (17 wells inside the perimeter fence and 26 wells outside the fence).

Based on the groundwater sampling data presented in Cameco’s annual compliance reports, the refinery operations are not causing any adverse impact to groundwater quality. The average uranium concentration in groundwater, however, appears to be increasing. Cameco attributes the increase to one specific monitoring well, BH #22, located just south of the main UO3 plant building and adjacent to the digestion and calcination process areas. The maximum sampled uranium concentration in the groundwater for this well was 18.5 µg/L in 2015, which is below the maximum acceptable concentration of 20 µg/L in Health Canada’s Guidelines for Canadian Drinking Water Quality (although the groundwater in the area is not used for drinking water). The maximum individual result from the other monitoring wells was 4.4 µg/L. Further, the average uranium result from all other monitoring wells at BRR, if BH #22 is removed from the calculation, was 0.6 µg/L, the same as in 2014.

The reason for the increase in concentration at BH #22 is not definitively known but may be attributable to slightly contaminated surface water run-off in the vicinity of the monitoring well. This location was used for temporary storage of empty uranium concentrate drums, prior to them being grit blasted. The historical inventory of empty concentrate drums, which originally numbered more than 100,000, has now been eliminated so this location is no longer used for the storage of empty drums. A number of cracks and openings in the asphalt around this monitoring well were sealed as a preventive measure last summer. Cameco is continuing to investigate and monitor results from this location.

CNSC staff concur with Cameco’s conclusions on the likely cause for the elevated concentrations as well as its path forward to address this matter. CNSC staff will continue to monitor the situation.Groundwater monitoring results are provided in table F-1, appendix F.

Surface water monitoring

Cameco continues to monitor surface water for uranium and other parameters at the location of the BRR outfall diffuser in Lake Huron. The concentration of uranium in the lake remains well below published federal and provincial guidelines. Surface water monitoring results are provided in table F-2, appendix F.

Soil monitoring

Cameco continues to collect soil samples on an annual basis, monitoring uranium concentrations in the upper layer of surface soil (i.e., 15 cm) to demonstrate that there are no long-term effects of its air emissions because there is no accumulation of uranium in the soil around the BRR facility. The results in 2015 remained consistent with the uranium soil concentrations detected in previous years. The average uranium soil concentrations observed near the facility were well below 23 µg/g, which is the most restrictive CCME soil quality guideline for residential and parkland use. Overall, uranium soil concentrations do not appear to increase in the area surrounding the facility, confirming that current BRR operations have no effects on soil quality. Soil sampling results are provided in table F-3, appendix F.

Gamma monitoring

A significant portion of radiological public dose in the town of Blind River attributable to BRR operations is due to gamma radiation sources. Therefore, it is essential to monitor gamma radiation effective dose rates at the fenceline of the BRR main site and the nearby golf course (critical receptor location) to ensure levels of gamma radiation are maintained ALARA. The gamma radiation effective dose rates for both locations are measured using environmental dosimeters. The annual average of fenceline gamma measurements at the BRR main site, in microsieverts (µSv), were 0.25 µSv/h (east), 0.26 µSv/h (north), 0.31 µSv/h (south) and 1.53 µSv/h (west) in 2015. The BRR main site sets an action level for gamma dose rates of 1.0 µSv/h at the north fence only. These measurements indicate that gamma dose rates are controlled and the public is protected.

Other monitoring

In 2013 and 2014, CNSC staff collected and analyzed a number of environmental samples in publicly accessible areas outside the perimeter of the facility under the IEMP. The results can be found on the CNSC’s IEMP Web page. Results obtained by the CNSC confirmed that the public and the environment in the vicinity of BRR are protected from the releases from the facility.

Protection of the public

Cameco is required to demonstrate that the health and safety of the public are protected from exposures to hazardous substances released from the BRR facility. The effluent and environmental monitoring programs currently conducted by the licensee are used to verify that releases of hazardous substances do not result in environmental concentrations that may affect public health.

CNSC receives reports of discharges to the environment through the reporting requirements outlined in the BRR licence and licence conditions handbook. The review of BRR’s hazardous (non-radiological) discharges to the environment indicates that no significant risks to the public or environment have occurred during this period.

Based on their reviews of the programs at BRR, CNSC staff concluded that the public continues to be protected from facility emissions.

Environmental risk assessment

Cameco indicated that it would implement three environmental protection standards by the end of 2017: CSA Group standards N288.4-10, Environmental monitoring programs at Class I nuclear facilities and uranium mines and mills; N288.5-11, Effluent monitoring programs at Class I nuclear facilities and uranium mines and mills; and N288.6-12, Environmental risk assessments at Class I nuclear facilities and uranium mines and mills. CNSC staff will review the respective BRR documents to make sure they address the compliance requirements of the CSA Group standards. Cameco currently has acceptable environmental programs in place to ensure the protection of the public and the environment.

3.4 Conventional health and safety

| 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|

| SA | SA | SA | FS | FS |

| For 2015, CNSC staff continued to rate the conventional health and safety SCA at BRR as "fully satisfactory." Overall, the compliance verification activities conducted by CNSC staff at BRR confirmed that Cameco continues to view conventional health and safety as an important consideration. Cameco has implemented an effective occupational health and safety management program, which has helped to keep its workers safe from occupational injuries; no LTIs have occurred for more than nine years. | ||||

Performance

A key performance measure for this SCA is the number of LTIs that occur per year. An LTI is an injury that takes place at work and results in the worker being unable to return to work and carry out their duties for a period of time. Per table 3-4, the number of LTIs remained at zero in 2015. BRR has not had an LTI in the past nine years.

| 2011 | 2012 | 2013 | 2014 | 2015 | |

|---|---|---|---|---|---|

| Lost-time injuries | 0 | 0 | 0 | 0 | 0 |

Practices

Cameco’s activities and operations at BRR are required to comply with not only the NSCA and its associated regulations but also with Part II of the Canada Labour Code. As such, Cameco is required to report incidents resulting in an injury to ESDC. CNSC staff receive copies of these reports.

BRR’s commitment to safety is captured in a safety charter signed by each employee and displayed at the entrance of the facility. Cameco has a Facility Health and Safety Committee that inspects the workplace and meets monthly to resolve and track any safety issues. CNSC staff frequently review the committee meeting minutes and associated corrective actions to verify that issues are promptly resolved.

Awareness

Cameco continues to develop and maintain a comprehensive occupational health and safety management program for the BRR site. During 2015, Cameco undertook nine initiatives to improve occupational health and safety. Workers are made aware of the conventional health and safety program as well as workplace hazards through training and ongoing internal communications with Cameco. CNSC staff continue to monitor the effectiveness of these improvement initiatives through regular onsite inspections.

4 Port Hope Conversion Facility

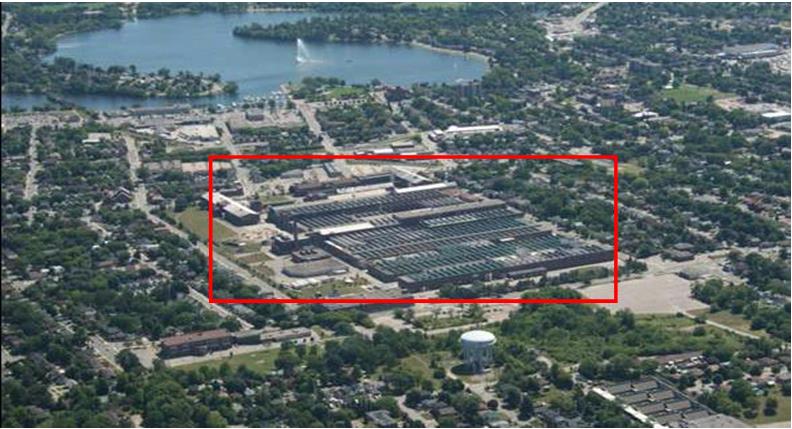

Cameco owns and operates the Port Hope Conversion Facility (PHCF) under an operating licence that expires on February 28, 2017. PHCF is located in the municipality of Port Hope, ON, situated on the north shore of Lake Ontario, approximately 100 kilometres east of Toronto. An aerial photograph of the site is shown in figure 4-1.

Figure 4-1: Aerial view of the Port Hope Conversion Facility

.jpg/object)

PHCF primarily converts UO3 powder produced by Cameco’s Blind River Refinery into uranium dioxide (UO2) and uranium hexafluoride (UF6). UO2 is used in the manufacture of CANDU reactor fuel, while UF6 is exported for further processing before being converted into fuel for light-water reactors.

In 2015, there were no licence amendments; however, there were two revisions to the PHCF licence conditions handbook, as described in table I-2, appendix I. Cameco submitted an application to renew its operating licence for PHCF in November 2015. The licence renewal hearing is scheduled the week of November 9, 2016 in the community of Port Hope, ON.

4.1 Performance

For 2015, CNSC staff continued to rate PHCF’s performance as "satisfactory" in all SCAs. The PHCF performance ratings for 2011 through 2015 are provided in table C-2, appendix C.

In 2015, Cameco made no significant changes to the processes it uses to ensure the physical design of the PHCF site is maintained and made no facility modifications that affected PHCF’s safety case. During the summer of 2015, the UO2 and UF6 plants underwent scheduled shutdowns to allow for planned maintenance activities and to allow employees to take vacation time. Cameco also started its 2015 clean-up project at PHCF that summer, which covered the removal and processing of obsolete equipment and the demolition of buildings 42 and 43 annex on the Centre Pier. After achieving the annual production targets, the UO2 and UF6 plants were safely shutdown in December 2015.

As outlined below, PHCF experienced a number of events or incidents that were reported to CNSC staff in 2015:

- In May 2015, PHCF staff recognized that a small spool section feeding potassium hydroxide should have been treated as a pressure-retaining component. Given that this line was not previously identified or maintained as a pressure retaining component, Cameco conducted a review to determine any other pressure-retaining components not previously identified. Cameco intends to replace the identified piping by the end of December 2015 to ensure that all pressure-retaining components meet the appropriate specifications. CNSC staff are satisfied with the measures taken and corrective actions identified by Cameco. CNSC staff will verify the completion of these corrective actions during an onsite inspection.

- In July 2015, a white, chalky substance was observed over portions of a building rooftop, piping infrastructure and on the ground. The source of the substance was traced to liquid discharges from one of the waste water evaporator stacks. Cameco took immediate actions to prevent further liquid discharges such as installing flow indicators, lowering the operating range of the evaporator level and increasing the frequency of building inspections. CNSC staff are satisfied with the compensatory measures and corrective actions taken by Cameco.

- In November 2015, Cameco reported two action level exceedances: one for a skin dose and the other for a routine uranium-in-urine pre-shift sample. These two action level exceedances are described in more detail in section 4.2 under the "Radiation protection program performance" heading.

In addition to these reportable events or incidents, Cameco notifies CNSC staff of the regulatory reports it makes to Environment and Climate Change Canada, the Ontario MOECC and the Municipality of Port Hope. CNSC staff review these reports and follows up with additional regulatory oversight activities, as appropriate.

Vision in Motion (VIM) is Cameco’s project to clean up and renew the PHCF. In 2015, Cameco carried out some clean-up and remediation work to further progress the planning and design development for VIM (e.g., test soil excavations, clean-up projects). In November 2015, Cameco submitted its application to renew its PHCF operating licence, which included information about the VIM project that will be carried out during the next licensing period.

In 2015, CNSC staff conducted five planned compliance inspections at PHCF to verify compliance with the NSCA and its regulations, Cameco’s operating licence and the programs used to meet regulatory requirements. These planned onsite inspections focused on the areas of waste management, environmental protection, training. A dedicated onsite inspection was also conducted to follow up on the corrective actions associated with events that occurred in 2014, and CNSC staff reviewed Cameco’s common-cause analysis report for the 2014 events. CNSC staff concluded that none of the findings from these regulatory oversight activities presented an immediate or unreasonable risk to the health, safety and security of workers, Canadians or the environment.

4.2 Radiation protection

| 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|

| SA | SA | SA | SA | SA |

| For 2015, CNSC staff continued to rate the radiation protection SCA at PHCF as "satisfactory." Cameco has implemented and maintained a radiation protection program as required by the Radiation Protection Regulations. | ||||

Application of ALARA

As required by the Radiation Protection Regulations, Cameco continued to implement radiation protection measures at PHCF in 2015 to keep radiation exposures and doses to persons ALARA, taking into account social and economic factors. Cameco establishes radiation protection objectives and ALARA targets on an annual basis. These objectives and targets include worker dose reduction initiatives and other projects that examine ways to reduce in-plant uranium-in-air concentrations. In 2015, Cameco achieved the majority of its ALARA targets at PHCF (which focused on radiation doses to workers) and achieved a high compliance rate for bioassay submissions by workers.

Worker dose control

Radiation exposures are monitored to ensure compliance with the CNSC’s regulatory dose limits and with keeping radiation doses ALARA. In 2015, radiation exposures at PHCF, as reported by Cameco, were well below the CNSC’s regulatory dose limits.

Cameco ascertains external doses using whole body dosimetry. Extremity dosimetry is only used on a case-by-case basis and is dependent on the work activities being carried out. For internal radiological exposures, Cameco’s Fuel Services Division holds a CNSC dosimetry service licence, which authorizes Cameco to provide in-house internal dosimetry services at PHCF. Internal dose is assessed and assigned at PHCF through two programs: urine analysis and lung counting

.Workers (including contractors) conducting work activities that present a reasonable probability of receiving an occupational dose greater than 1 mSv are identified as NEWs at PHCF. In 2015, total effective dose was assessed for 862 NEWs at PHCF, consisting of 422 Cameco employees and 440 contractors. The maximum effective dose received by a NEW in 2015 was 7.0 mSv, or approximately 14 percent of the regulatory effective dose limit of 50 mSv in a one-year dosimetry period. For the five-year dosimetry period from 2011–15, the maximum individual effective dose to a NEW at PHCF was 23.4 mSv. This radiation dose result represents approximately 23 percent of the regulatory dose limit of 100 mSv per five-year dosimetry period.

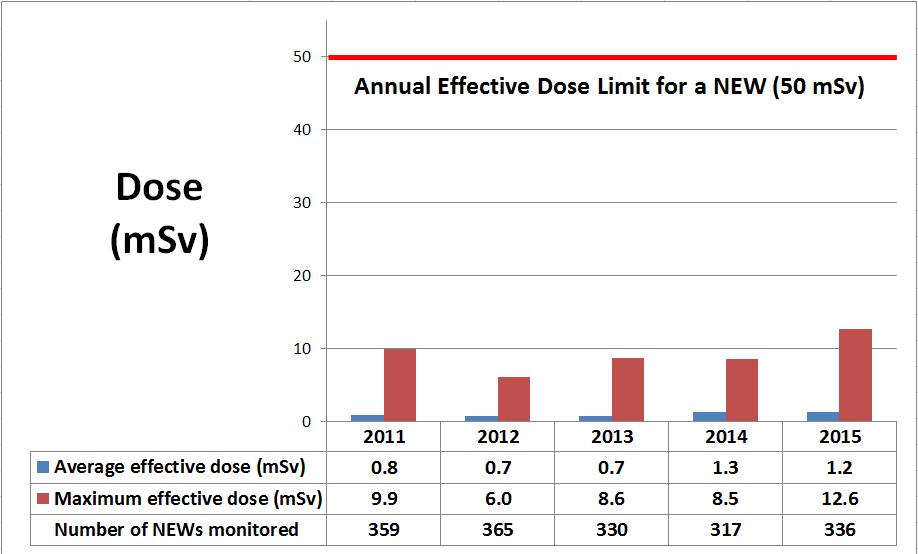

Figure 4-2 provides the average and maximum effective doses to NEWs at Cameco’s PHCF between 2011 and 2015.

.jpg/object)

Description

| 2011 | 2012 | 2013 | 2014 | 2015 | |

|---|---|---|---|---|---|

| Note: The number of NEWs monitored from 2011 to 2014 has been corrected from previously reported values of 442, 450, 823 and 753. This is a correction to the results reported in Regulatory Oversight Report for Uranium and Nuclear Substance Processing Facilities in Canada: 2014. The average effective doses for the years 2011 to 2013 have also been corrected (previously reported as 1.9, 2.0 and 0.7 mSv), as well as the maximum effective dose value for 2012 (previously reported as 7.0 mSv). | |||||

| Average effective dose (mSv) | 0.8 | 1.1 | 0.8 | 0.8 | 0.6 |

| Maximum effective dose (mSv) | 8.8 | 6.9 | 6.6 | 5.4 | 7.0 |

| Number of NEWs monitored | 957 | 902 | 793 | 780 | 862 |

The average and maximum effective doses at PHCF were relatively stable between 2011 and 2015.

Annual average and maximum equivalent (skin) dose results from 2011 to 2015 are provided in table E-16, appendix E. In 2015, the maximum skin dose received by a NEW at PHCF was 23.4 mSv, which is approximately five percent of the regulatory equivalent dose limit of 500 mSv in a one-year dosimetry period. The maximum annual equivalent (skin) dose received by a NEW between 2011 and 2015 was 181.4 mSv – the result of a 2011 event where a worker had a finger laceration with contamination due to a maintenance activity. While this value is high in comparison with the routine skin exposures observed over these years, it still only represents approximately 36 percent of the regulatory equivalent dose limit of 500 mSv per year.

The majority of Cameco’s administration and technical support staff whose job functions do not require them to be in uranium processing areas, as well as visitors to PHCF, are identified as non-NEWs. In 2015, the maximum effective dose received by a non-NEW was 0.29 mSv and averaged less than 0.1 mSv, which is well below the annual regulatory dose limit of 1 mSv for a member of the public.

Radiation protection program performance

The performance of the PHCF radiation protection program was assessed in 2015 through various CNSC staff compliance activities. Cameco’s compliance with the Radiation Protection Regulations and CNSC licence requirements at PHCF was found to be acceptable.

Action levels for radiological exposures are established as part of the radiation protection program. If an action level is reached, it triggers Cameco staff to establish the cause, notify the CNSC and, if applicable, restore the effectiveness of the program. In 2015, there were two instances at PHCF where an action level was reached. Cameco completed investigations and established corrective actions in each instance to the satisfaction of CNSC staff.

In the first instance, an operator working in the UF6 plant submitted a urine sample that was at the action level for uranium in urine: 65 µg of uranium per litre. The committed effective dose assigned to the worker was 0.12 mSv, well below the annual effective dose limit of 50 mSv for a NEW. After an investigation, Cameco suspected that the worker’s respirator seal was compromised or the worker removed the respirator too soon after completing work, compromising the respirator’s effectiveness in preventing an intake of uranium. In response, the worker was coached on the proper use of personal protective equipment (PPE), including the manner in which PPE should be removed. A safety bulletin was also issued to all onsite workers outlining the proper methods for removing PPE. Cameco has a number of initiatives that are expected to improve protection of workers in the UF6 plant, including a review of PPE requirements for operators working in the plant’s ash can room.

In the second instance, a maintenance employee working in the UF6 plant recorded a monthly skin dose on his dosimeter of 17.4 mSv, which exceeded the 15 mSv per month action level for skin dose. Still, this dose was well below the annual equivalent dose limit of 500 mSv for a NEW. Cameco completed an investigation and determined that the worker had been part of a non-routine work assignment in which the worker was situated in an area where external dose rates were elevated, thereby contributing to the slightly elevated skin dose. As corrective actions, Cameco highlighted initiatives that were underway to enhance the protection of workers, including a review of safe work practices.

Radiological hazard control

Radiation and contamination control programs have been established at PHCF according to CNSC regulatory requirements to control and minimize radiological hazards and the spread of radioactive contamination. Methods of control include the use of radiation zone controls and monitoring to confirm the effectiveness of the programs. In-plant air monitoring and radiation dose-rate surveys conducted in 2015 did not identify any adverse trends and were consistent with expected radiological conditions. Contamination monitoring conducted by PHCF staff did not identify any adverse trends and no instances of contamination were detected in clean areas.

Estimated dose to the public

The maximum effective doses to a member of the public at PHCF for the years 2011 to 2015 are shown in table 4-1. Doses to the public are well below the PHCF operating release level of 0.3 mSv/year. The CNSC regulatory dose limit for a member of the public is 1 mSv/year.

| Dose data | 2011 | 2012 | 2013 | 2014 | 2015 | Regulatory limit |

|---|---|---|---|---|---|---|

| Maximum effective dose (mSv) | 0.019 | 0.029 | 0.021 | 0.012 | 0.006 | 1 mSv/year |

4.3 Environmental protection

| 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|

| SA | SA | SA | SA | SA |

| For 2015, CNSC staff continued to rate the environmental protection SCA at Cameco’s PHCF as "satisfactory." Uranium releases to the environment continue to be controlled and monitored to comply with the conditions of the facility’s operating licence and regulatory requirements. The releases of hazardous substances from the facility to the environment are controlled in accordance with the Ontario MOECC’s applicable requirements. All the releases to the environment were well below regulatory limits during 2015. Fenceline gamma measurements, groundwater monitoring, surface water monitoring, soil sampling, vegetation and ambient air data indicate that the public and the environment continue to be protected from facility releases. | ||||

Effluent and emissions control (releases)

To control the release of radioactive and hazardous substances into the environment, CNSC licensees are required to develop and implement policies, programs and procedures that comply with all applicable federal and provincial environmental protection regulations. Licensees are also required to have suitably trained and qualified staff to effectively develop, implement and maintain their environmental protection programs.

Atmospheric emissions

Cameco monitors uranium, fluorides and ammonia released from stacks at PHCF. The monitoring data in table 4-2 demonstrates that stack emissions from the facility in 2015 continued to be effectively controlled and remained consistently below their respective licence limits. No action levels were exceeded at any time in 2015.

| Location | Parameter | 2011 | 2012 | 2013 | 2014 | 2015 | Licence limit |

|---|---|---|---|---|---|---|---|

| UF6 plant | Uranium (kg/h) | 0.0051 | 0.0042 | 0.0051 | 0.0012 | 0.0017 | 0.290 |

| Fluorides (kg/h) | 0.0199 | 0.0160 | 0.0190 | 0.0130 | 0.0170 | 0.650 | |

| UO2 plant | Uranium (kg/h) | 0.0013 | 0.0012 | 0.0013 | 0.0012 | 0.0012 | 0.150 |

| Ammonia (kg/h) | 2.4 | 1.9 | 2.0 | 2.2 | 2.4 | 58 |

Liquid effluent

Cameco’s operating licence does not allow PHCF to discharge any process waste water effluent. For 2015, there were no process liquid discharges from the facility. Cameco continues to evaporate rather than discharge process liquid effluent.

PHCF does discharge non-process liquid effluent such as cooling water and sanitary sewer discharges. Cameco monitors these releases in compliance with the requirements of other regulators that have jurisdiction. For the current and previous licensing periods, CNSC staff reviewed these monitoring results and found the levels to be consistently low and acceptable, and concluded that the licence requirement not to discharge process waste water effluent has been met.

Environmental management system

Cameco has developed and is maintaining an EMS that provides a framework for integrated activities with respect to the protection of the environment at PHCF. Cameco’s EMS is described in its Environmental Management Program Manual and includes activities such as establishing annual environmental objectives and targets, which are reviewed and assessed by CNSC staff through compliance verification activities. The EMS is verified through an annual management review by Cameco where minutes and follow-up to outstanding issues are documented. CNSC staff, as part of their compliance verification activities, review these minutes and follow up on any outstanding issues with Cameco staff. The results of this review demonstrate that Cameco is conducting an annual management review per CNSC requirements and identified issues are being addressed.

Assessment and monitoring

Cameco’s environmental monitoring programs serve to demonstrate that the site emissions of nuclear and hazardous materials are properly controlled. They also provides data for estimates of annual radiological dose to the public to make sure the public dose attributable to Cameco’s PHCF operations is ALARA and below the annual regulatory dose limit of 1 mSv. The principal monitoring activities are focused on monitoring the air, groundwater, surface water, soil, vegetation and gamma radiation around the facility.

Uranium in ambient air

Cameco measures uranium in the ambient air at several locations around the facility to confirm the effectiveness of emission abatement systems and to monitor the impact of the facility on the environment. For 2015, the results from these samples show that uranium in air as suspended particulate has consistently remained very low: the highest annual average concentration (among the sampling stations) of uranium in ambient air measured around the facility in 2015 was 0.003 µg/m3, well below the Ontario MOECC’s standard for uranium in ambient air of 0.03 µg/m3.

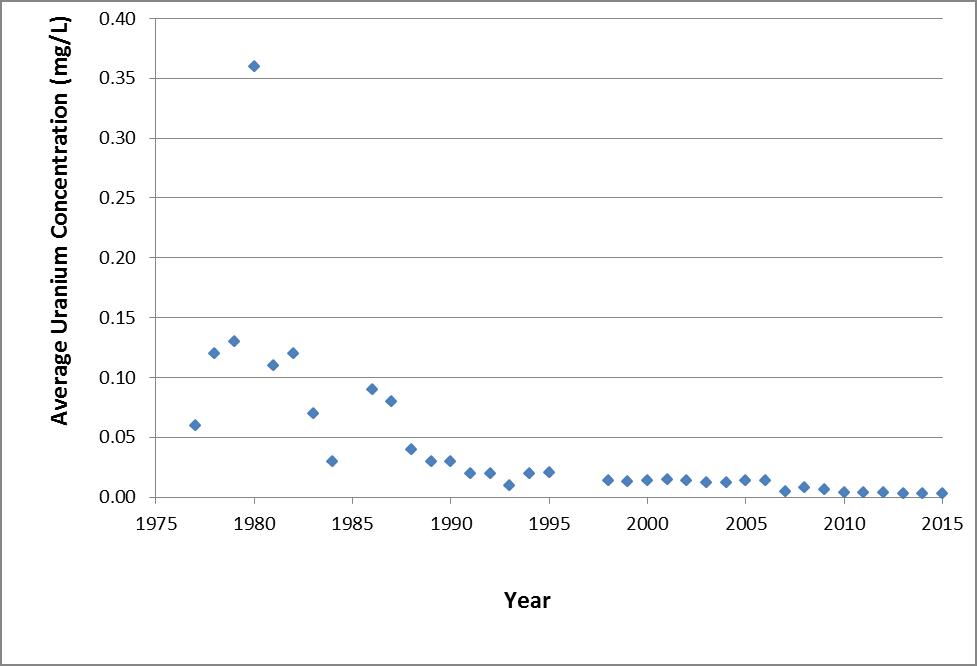

Groundwater monitoring

Currently, the groundwater quality at PHCF is assessed using samples from:

- 12 active pumping wells on a monthly basis

- 67 monitoring wells in the overburden on a quarterly basis

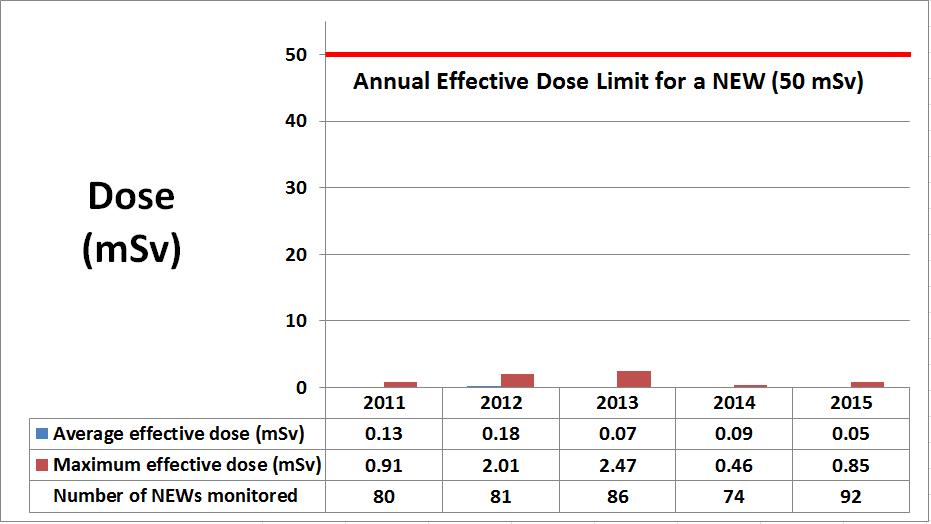

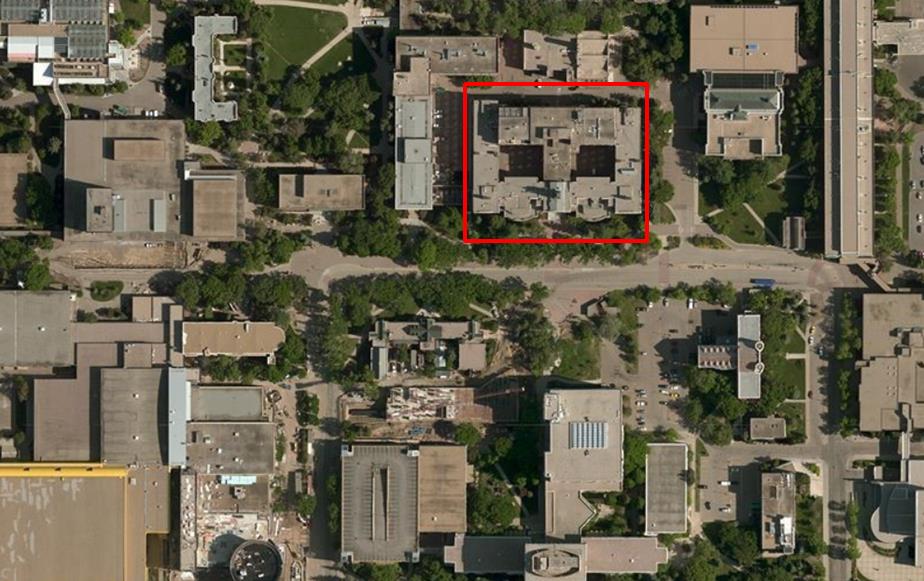

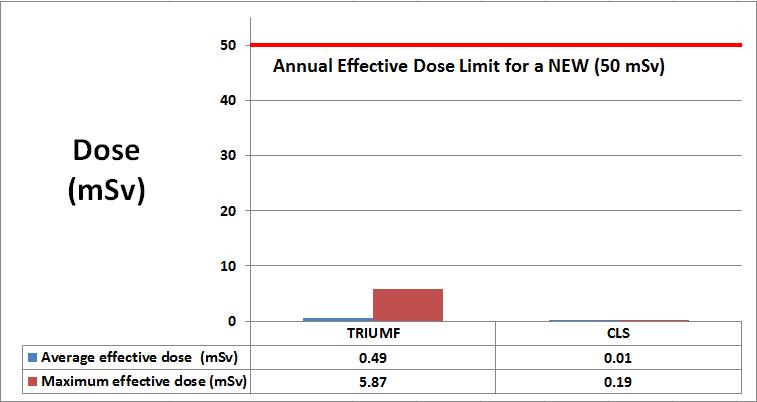

- 15 monitoring wells in the bedrock on an annual basis