Regulatory Oversight Report on the Use of Nuclear Substances in Canada: 2019

Regulatory Oversight Report on the Use of Nuclear Substances in Canada: 2019 (PDF)

Table of contents

- Executive Summary

- Part I: Use of Nuclear Substances in Canada: 2019

- Part II: Class IB Accelerators in Canada: 2018-2019

- Appendix A: Regulatory Program for the Use of Nuclear Substances

- Appendix B: Compliance Performance

- Appendix C: Enforcement Actions Issued in 2019

- Appendix D: Doses to Workers

- Appendix E: Reported Events

- Appendix F: Inspections conducted in 2019

- Appendix G: Regulatory Program for Class IB Accelerator Facilities

- Appendix H: Safety and Control Rating for Class IB Accelerator Facilities

- Appendix I: Effective Doses to the Public from Class IB Accelerator Facilities

- Appendix J: Lost Time-Injury Rate for Class IB Accelerator Facilities

- Appendix K: Effective Doses to Workers at Class IB Accelerator Facilities

- Appendix L: Events at Class IB Accelerator Facilities

- Appendix M: Compliance Rating Level

- Appendix N: Regulatory Documents

- Appendix O: Relevant Regulatory References

- Appendix P: Categorization of Sealed Sources

Executive Summary

This document presents the Regulatory Oversight Reports (ROR) for the Directorate of Nuclear Substance Regulation (DNSR) for the activities falling under its regulatory responsibilities. This report also covers Waste Nuclear Substance licenses, regulated by the Directorate of Nuclear Cycle and Facilities Regulation. The report is provided in two parts:

- Part I: Use of Nuclear Substances in Canada: 2019

- Part II: Class IB Accelerators in Canada: 2018-2019

The Canadian Nuclear Safety Commission (CNSC) regulates the use of nuclear energy and materials to protect health, safety, security and the environment, implements Canada’s international commitments on the peaceful use of nuclear energy, and disseminates objective scientific, technical and regulatory information to the public. Licensees are responsible for operating their facilities safely and are required to implement programs that make adequate provision for meeting legislative and regulatory requirements.

To assess the safety performance of licensees, the CNSC conducts regulatory oversight activities including inspections, reviews of reports submitted by licensees, reviews of events and incidents, and general communication and exchanges of information with licensees.

CNSC staff use many metrics to evaluate licensees’ safety performance. This report uses a subset of these which – when taken together – have been determined to provide a well-rounded picture of performance for the licensees covered by this report. The metrics used in this report are:

- compliance performance

- enforcement actions

- doses to workers

- reported events

CNSC staff use a well-established Safety and Control Area Framework in evaluating each licensee’s safety performance. The framework includes 14 safety and control areas (SCAs) covering all technical areas of regulatory oversight. While CNSC staff review and assess performance in each SCA (if applicable), only those that are most useful in providing a good overall indication of the safety performance of the licensees are covered in the ROR, as explained below.

For Part I, the ROR will cover SCA ratings for management system, operating performance, radiation protection, and security. In addition, it will provide the Commission information about the effort on the part of CNSC to regulate these licensees, along with stakeholder engagement.

For Part II, the ROR will include ratings for all 14 SCAs and will focus on management system, radiation protection, and conventional health and safety SCAs for both TRIUMF and the Canadian Light Source for calendar years 2018 and 2019. Part II will also discuss CNSC's regulatory oversight and the facilities' public information and disclosure programs.

For both parts of the ROR, the main body of the report is meant to provide a high-level overview of the CNSC’s regulatory efforts, along with the licensees’ performance. The detailed data to support this overview can be found in the appendices: appendices A to F cover data linked to Part I of this report; appendices G to L link to Part II; and appendices M to P provide generic information applicable to both.

Part I: Use of Nuclear Substances in Canada: 2019

The Regulatory Oversight Report on the Use of Nuclear Substances in Canada: 2019 summarizes the safety performance of 1,494 licensees, which hold a total of 2,090 licences. Additional data on licensees is available in Appendix A. The CNSC authorizes these licensees to use nuclear substances and prescribed equipment in the medical, industrial, academic and research, and commercial sectors. Waste nuclear substance licences are included within the commercial sector. Section 4 of the 2018 ROR describes the sectors covered in this report.

For the purpose of Part I, CNSC staff evaluate safety performance by presenting licensees’ regulatory compliance in select Safety and Control Areas (SCAs) (that is, management system, operating performance, radiation protection and security), as well as enforcement actions, effective doses to workers and reported events.

In 2019, as part of the ongoing regulatory oversight of licensees, CNSC staff conducted compliance verification activities consisting of field inspections, desktop reviews and technical assessments of licensee activities. The evaluations of findings for the SCAs covered in Part I show that, overall, licensees made acceptable provision to protect health, safety, security, and the environment from the use of nuclear substances and prescribed equipment, and took the measures required to implement Canada’s international obligations. Based on these evaluations, CNSC staff conclude that the use of nuclear substances and prescribed equipment in Canada remains safe and secure.

I.1 Compliance Performance

During licensing and compliance activities, CNSC staff review the licensee’s (or applicant’s) performance within each relevant SCA by reviewing licensee documents and conducting inspections. Owing to the broad nature of the different activities conducted by the licensees covered in Part I, not all SCAs apply to all activities or all licensees. Although not incorporated into Part I, all relevant SCAs are assessed during compliance inspections and reviews of licensees’ documents, and a compliance rating is assigned for each SCA. Each SCA covers multiple items: some of these are administrative in nature and are considered relatively low risk, while others are linked to an immediate risk to health safety and security, and therefore any findings against these items during an inspection must be addressed immediately. Licensees are given a below expectation rating in an SCA if they are non-compliant in at least one item of an SCA, regardless of the risk.

All required corrective actions arising from below-satisfactory performance are tracked and followed up by CNSC staff to ensure that all items of non-compliance are addressed to the satisfaction of the CNSC. For any instances of non-compliance that pose immediate risk to health, safety and security enhanced enforcement actions, such as orders or Administrative Monetary Penalties, may be taken.

In Part I, the performance of a subset of the SCAs evaluated during inspections is reviewed and reported. The following four SCAs are the most relevant indicators of safety performance for licensees in the sectors covered in Part I: management system, operating performance, radiation protection and security. These SCAs are applicable to most of the licensees covered by Part I and, together, provide an indication of licensees’ overall safety performance. Appendix M provides a description of the rating framework.

In 2019, CNSC staff conducted 863 inspections across the four sectors. Overall, licensees showed satisfactory compliance ratings in all of the SCAs examined in Part I. A list of inspections performed in 2019 is available in Appendix F. Where items of non-compliance were identified, CNSC staff ensured that licensees took appropriate corrective actions. Licensees immediately addressed any items of non-compliance that had immediate risks to health, safety or security.

I.1.1 Management System

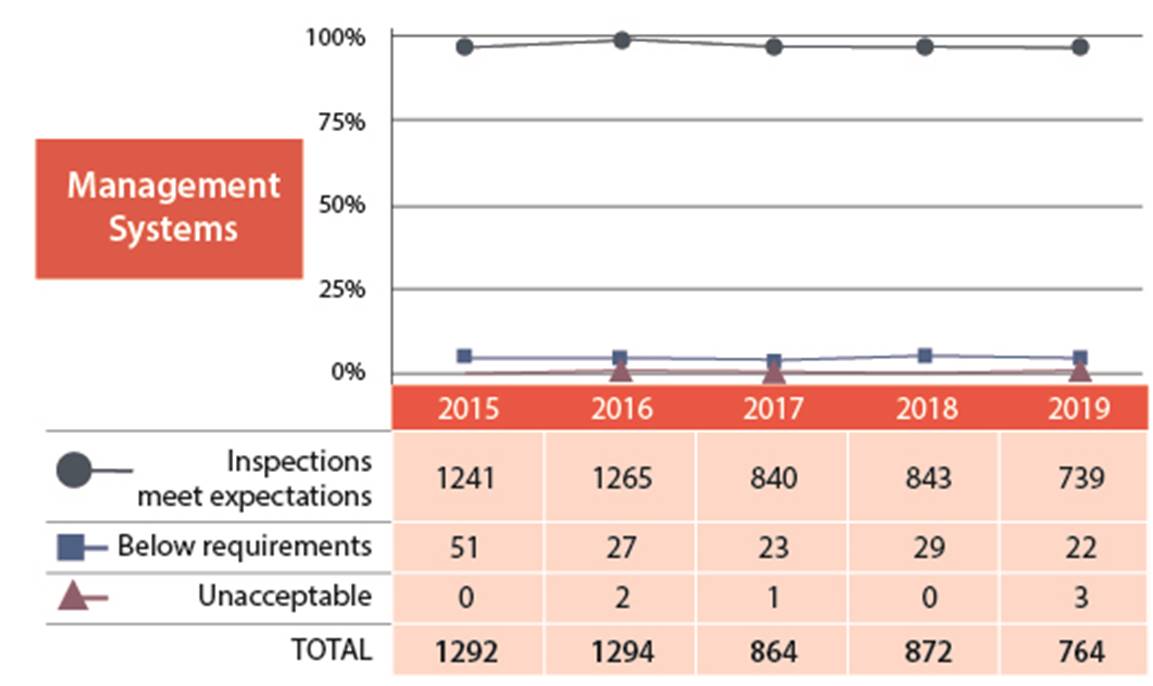

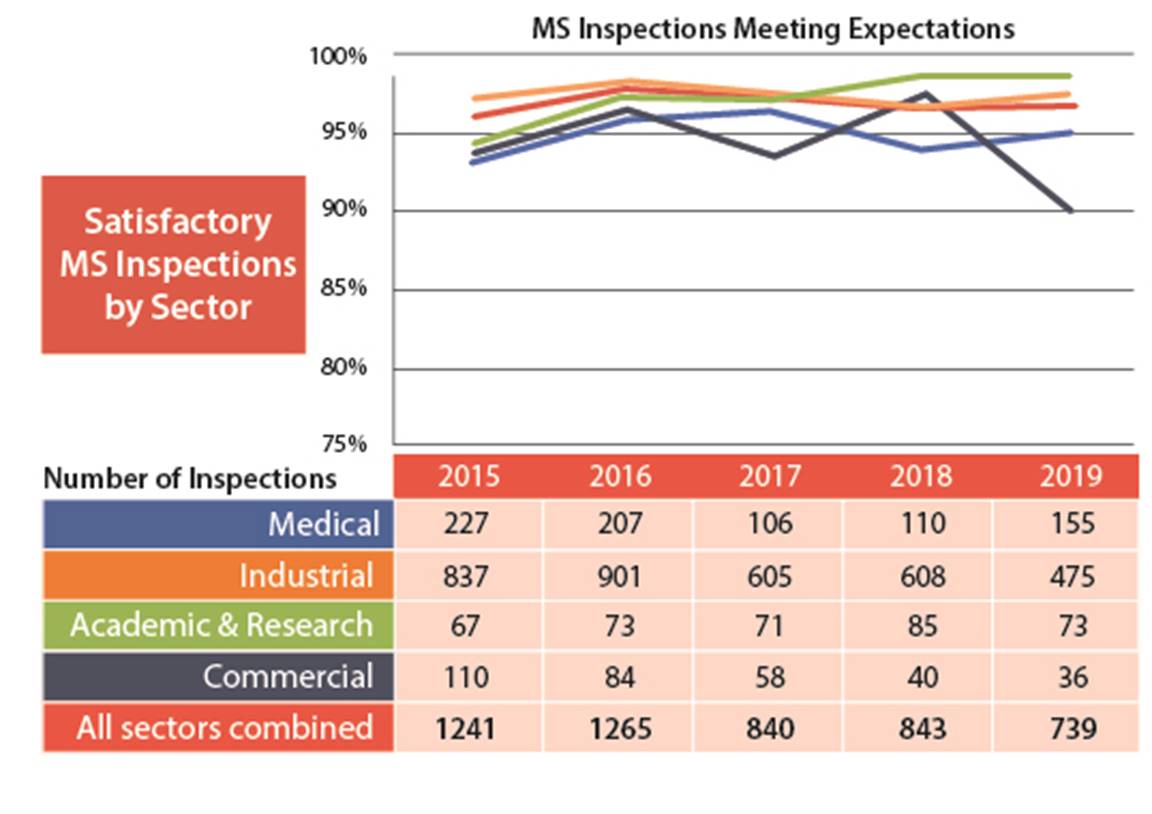

In 2019, licensees continued to maintain strong performance in the management system SCA. Overall, 97% of the licensees inspected received ratings of fully satisfactory or satisfactory for this SCA). The management system SCA has been performing with similar results over the past few years.

Refer to Appendix B.1 for additional information.

I.1.2 Operating Performance

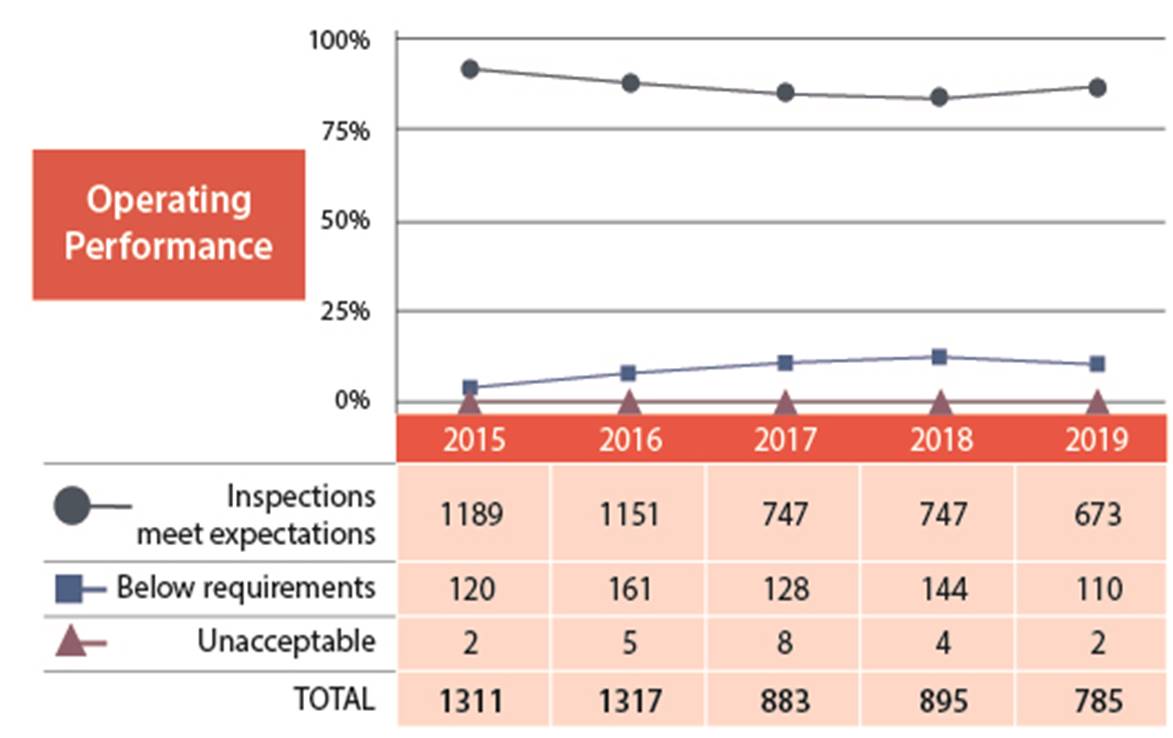

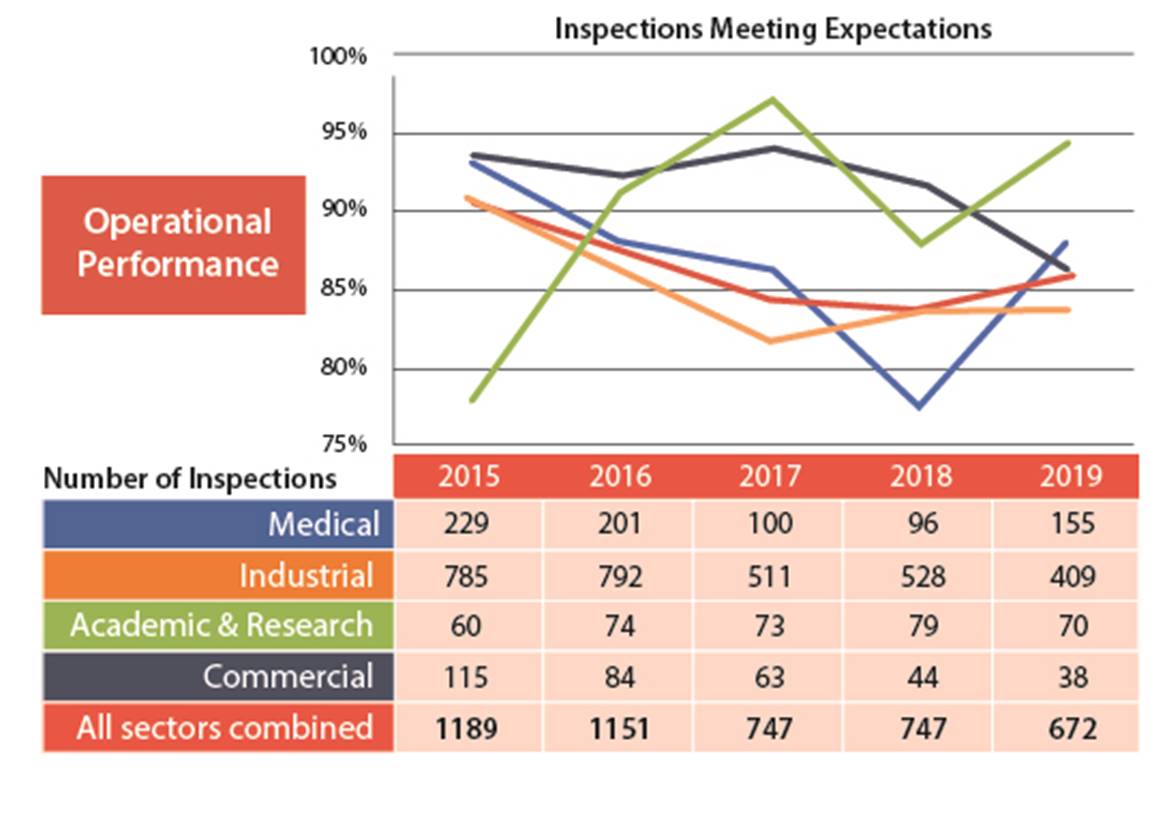

In 2019, licensees’ performance in the operating performance SCA improved from previous years. This is a reversal from the previous years that showed a slow decline. Of the licensees inspected, 86% received ratings of fully satisfactory or satisfactory for this SCA.

The only decline was in the commercial sector, although the overall results for this sector are still at 89% fully compliant. For context, this means four of the 36 licensees inspected in the commercial sector had a non-compliance in this SCA, none of which were a concern. In creating its inspection plan for 2019, DNSR prioritized its most overdue medium risk licensees over well performing high risk licensees. Because of this approach, a reduction in performance in the medium risk use types, including those in the commercial sector, was expected. This is the first year a decline in this sector was observed; this will be evaluated in upcoming years to see if this decline is a trend or single occurrence.

Refer to Appendix B.2 for additional information.

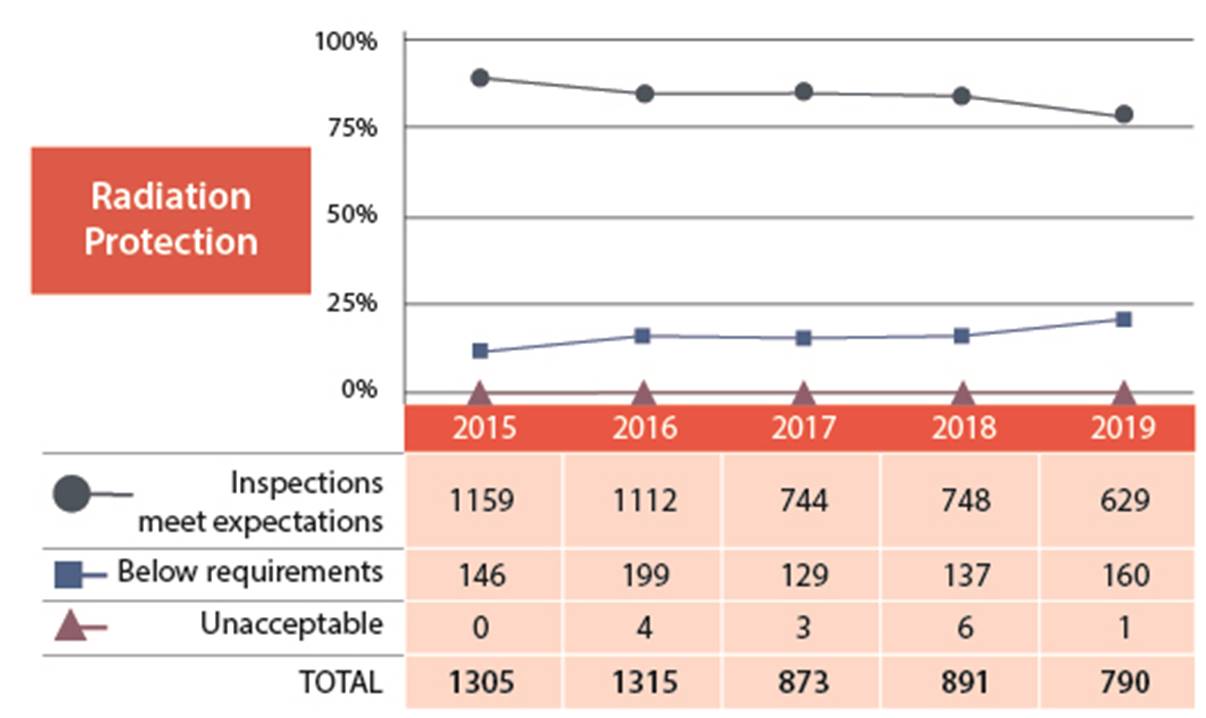

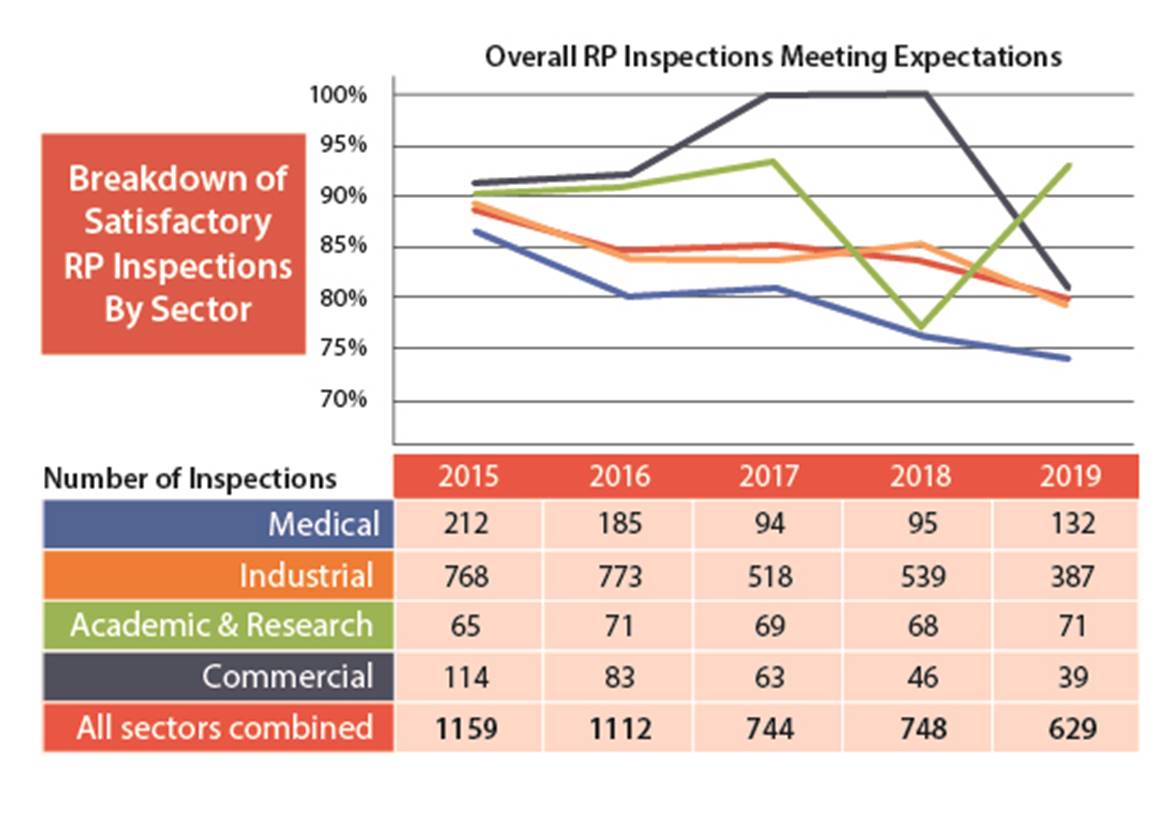

I.1.3 Radiation Protection

Licensee’s overall performance in the radiation protection SCA declined in 2019, with 80% of licensees receiving ratings of fully satisfactory or satisfactory. The decreases were all medium risk licensees.

As with the operating performance SCA, the increase in the number of licensees with below expectations ratings in the radiation protection SCA may be due to prioritizing medium risk licensees that were overdue for inspection, particularly within the medical sector and the industrial sector, especially portable gauge licensees. The focus was on licensees that had not been inspected in the last five years, licensees with a poor compliance history and new licensees that had not been inspected. This focus provides a possible rationale for the observed decline in performance across this SCA. In addition, there was an increased focus from the CNSC inspectors to look at the licensee’s implementation of the radiation protection program and management oversight of their operational activities, especially for licensees that have not been inspected for some time. This may also have contributed to the increased number of non-compliances in that area and, therefore, contributed to the overall decline in performance across this SCA. Both the medical licensees and the portable gauge licensees were highlighted in the case studies provided in the 2018 ROR. The regulatory strategy described in those case studies was to target these licensees using a performance-based inspection, observing workers performing their duties. This inspection approach has improved detection of common areas of non-compliance, which is another possible explanation for the perceived decline in performance in this SCA.

The performance of the radiation protection SCA will continue to be monitored in order to determine if additional actions are required. The inspection frequency for medium risk licensees is every two to five years so it may take a few years before improvement is noticed on subsequent inspections.

Refer to Appendix B.3 for additional information.

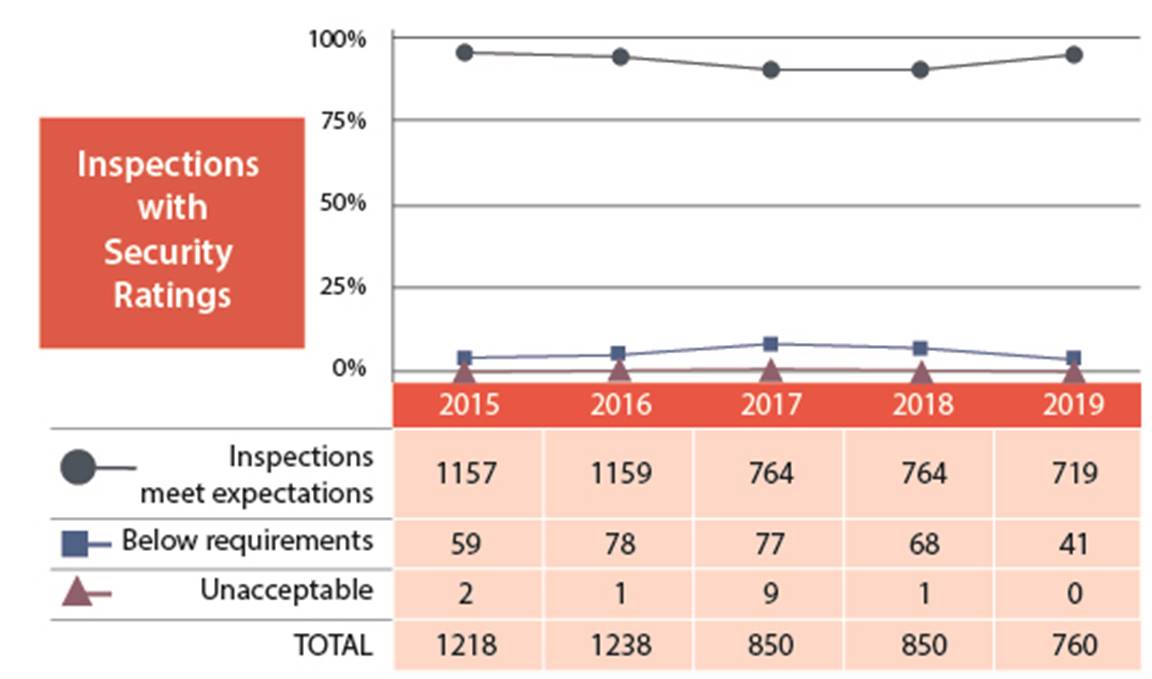

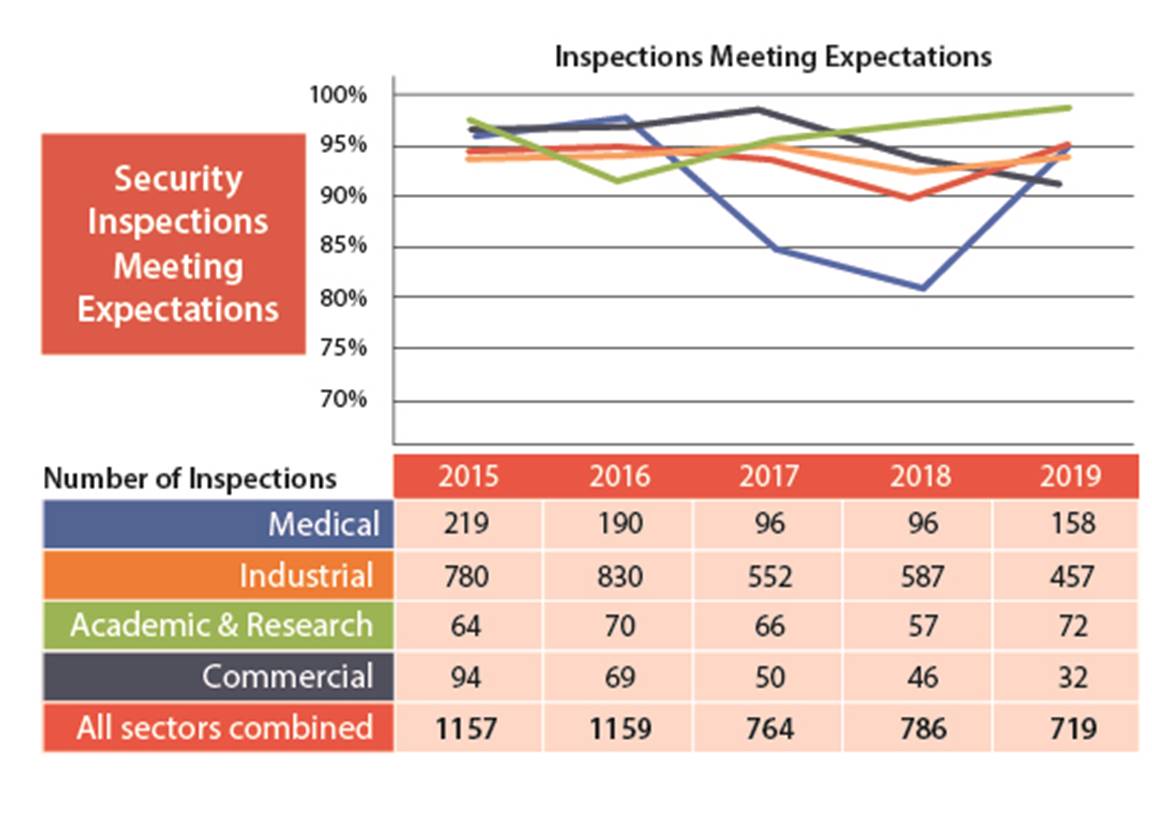

I.1.4 Security

In the security SCA, 95% of the licensees inspected demonstrated that they have adequate provisions in place to prevent the loss, sabotage, illegal use, illegal possession or illegal removal of nuclear substances and prescribed equipment in their care and control. This SCA performance is up almost 5% in 2019 from the 2018 and 2017 results. The 2019 results are trending at similar levels to 2015 and 2016. This is in keeping with the analysis in the 2018 ROR, which predicted a temporary period of lower performance as licensees adjusted to the new security requirements in REGDOC-2.13.2.

Refer to Appendix B.4 for additional information.

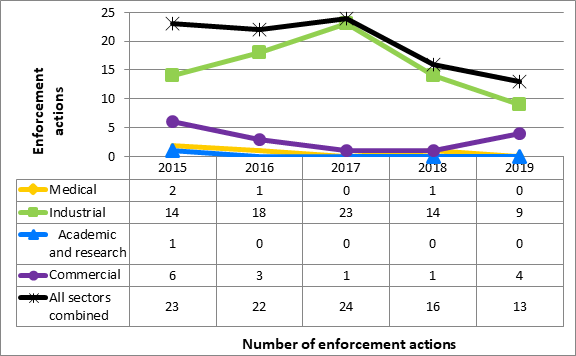

I.2 Enforcement

The CNSC uses a graduated approach to enforcement to encourage compliance. When non-compliance (or continued non-compliance) has been identified, CNSC staff assess the significance of the non-compliance and determine the appropriate enforcement action.

In 2019, the CNSC initiated 13 escalated enforcement actions against licensees in the four sectors. There were no administrative monetary penalties (AMPs) issued in 2019. Most of the enforcement actions were taken against licensees in the industrial sector, consistent with trends from previous years. Out of 13 enforcement actions, 10 are closed as of the drafting of this ROR, meaning the CNSC is satisfied that the licensee has addressed the conditions of the order. Any high risk or immediate health and safety findings were immediately addressed. In three cases, licensees that received orders have yet to comply with the terms and conditions of their orders and the orders remain open. The CNSC is actively working with the licensees in these orders to ensure that order requirements are addressed. Refer to Appendix C for further details on enforcement actions taken in 2019.

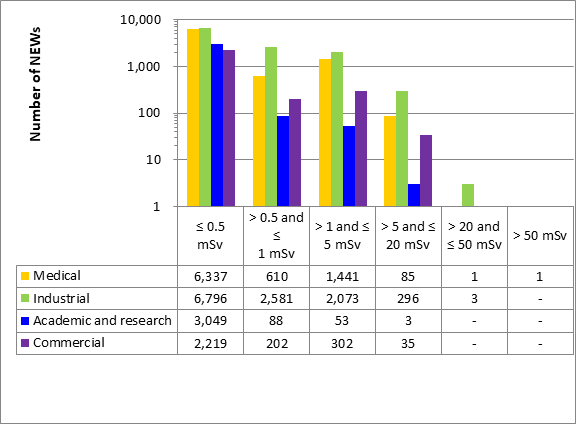

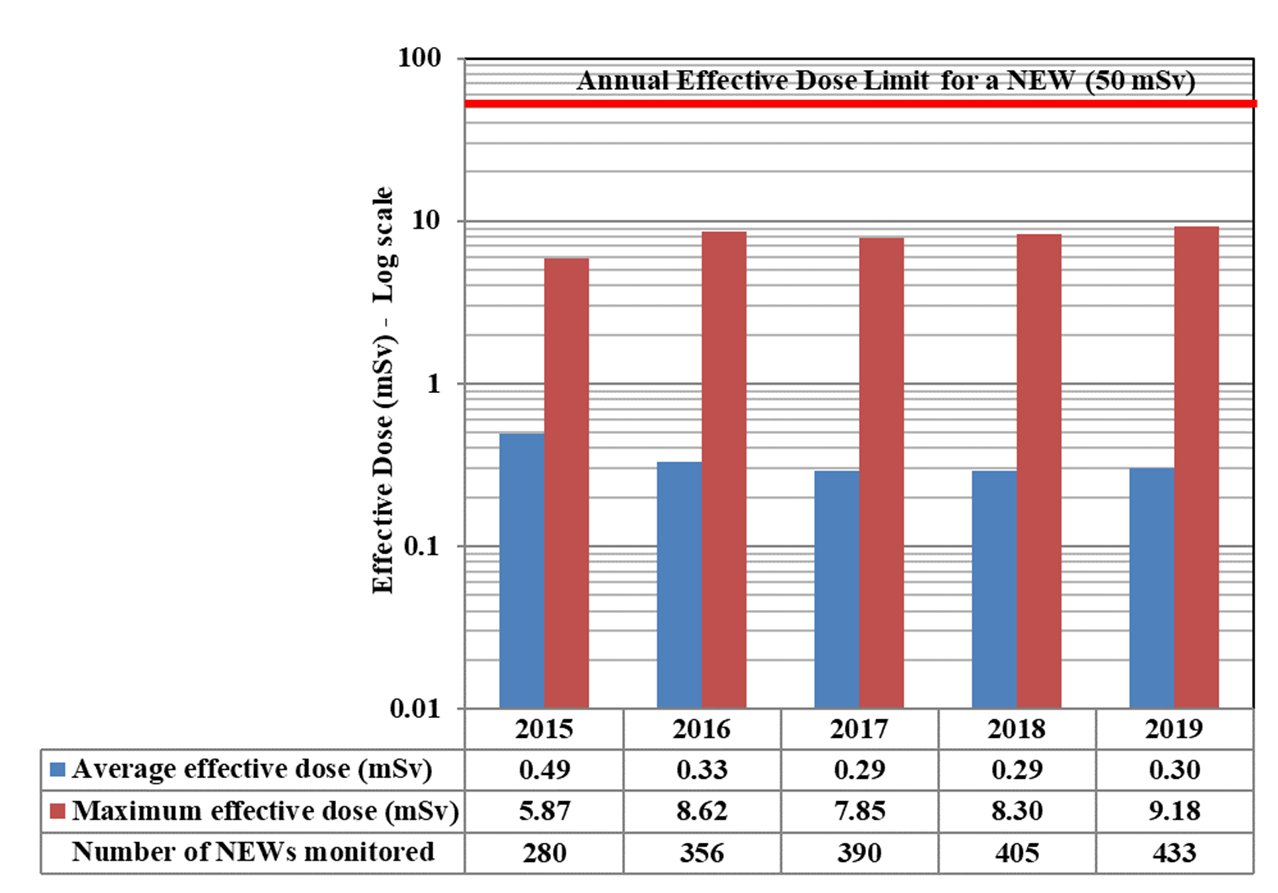

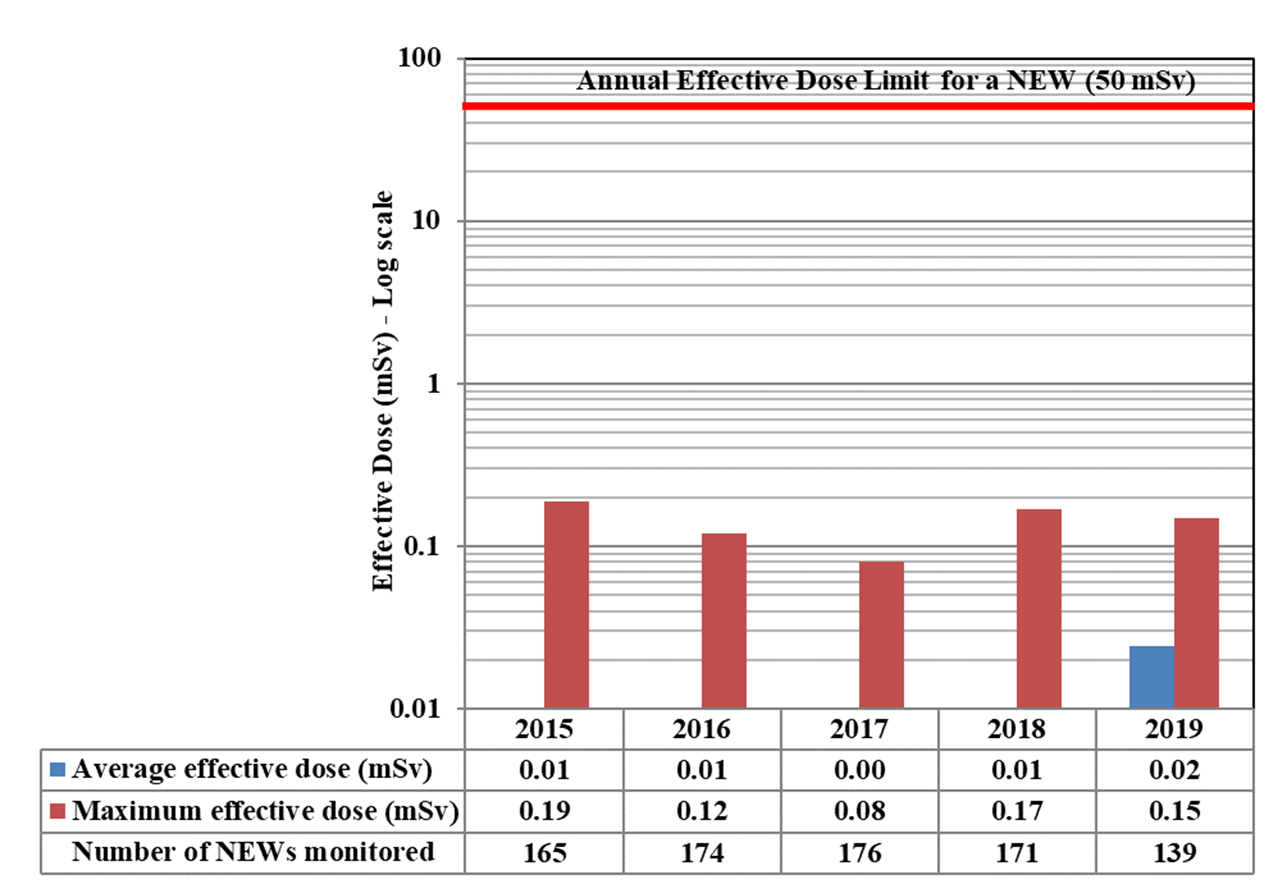

I.3 Effective Doses to Workers

Licensees are required to keep radiation doses to persons below regulatory limits and ALARA in accordance with the radiation protection programs established under the CNSC licences.

In 2019, doses were monitored for 63,015 workers in the four sectors covered in Part I. Of those workers, 26,539 were classified as nuclear energy workers (NEWs). The remaining 36,476 were not classified as NEWs and are referred to as non-NEWs in the report. Exposures to radiation continued to be very low for workers in 2019, consistent with previous reporting years. Additional information on effective doses to workers is in Appendix D.

In 2019, one NEW received a whole body dose above the regulatory limit of 50 mSv. The CNSC was notified that a worker received a dose of 57 mSv in November 2019. CNSC staff presented information on this event at the Commission hearing in June 2020. More information on this event can be found in Appendix E.

One non-NEW received a whole body dose above the regulatory limit of 1 mSv. More information on this event can be found in Appendix E.

In both of these cases, the doses received do not pose a risk of radiation-related health effects.

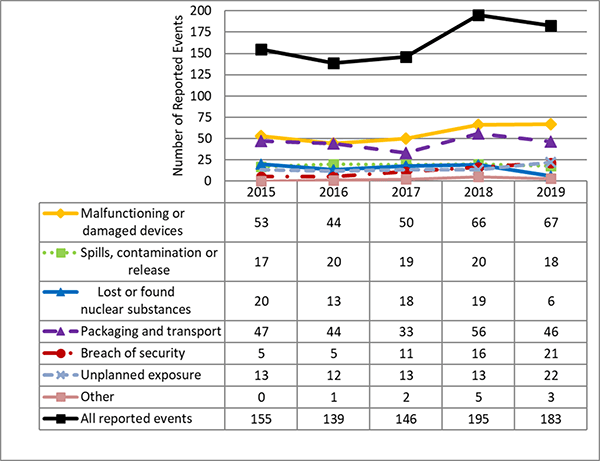

I.4 Reported Events

CNSC staff assessed the 183 eventsFootnote 1 reported by licensees covered in Part I. Reported events have been ranked using the International Nuclear and Radiological Event Scale (INES). Of these, 181 were ranked as level 0 (no safety significance), one was ranked as level 1 (anomaly) and one was ranked as level 2 (incident). These are the same events described in the previous section on Effective Doses to workers. The INES level 1 event is the non-NEW that received a whole body dose above the regulatory limit of 1 mSv. The INES level 2 event is the event where the NEW received a whole body dose above the regulatory limit of 50 mSv. Refer to Appendix E for the list of reported events.

For all of the events reported, licensees implemented appropriate response measures to mitigate the impacts of the events and to limit radiation exposure to workers and the public. CNSC staff reviewed the measures and found them to be satisfactory.

I.5 Case Studies in Regulatory Intervention

CNSC staff monitor the performance of licensees across all sectors, using various metrics. When

these metrics indicate that the performance is not meeting expectations, or is declining, CNSC staff develop regulatory strategies to address the situation. Once the strategies have been implemented, CNSC staff monitor their effectiveness and adjust them if necessary.

Two case studies on licensees from the commercial sector are presented in this ROR. The first is a case study on an Iodine-131 (I-131) Processing licensee, Isologic Innovative Radiopharmaceuticals Ltd. (IIR), and the second is on a Positron Emission Tomography (PET) isotope cyclotron and associated processing laboratories, Montreal Neurological Institute and Hospital. The case studies are not intended to be punitive, they are intended to demonstrate lessons learned from a regulatory oversight perspective and actions taken by licensees that resulted in improvements in their programs. These lessons could be implemented by other licensees.

I.5.1 I-131 Processing Facility

I.5.1.1 Introduction

I-131 is a radioisotope that has been used in the Nuclear Medicine industry for decades. It is used to diagnose and treat thyroid disorders, as well as to diagnose certain neuroendocrine tumours in both adults and children. I-131 is also used in veterinary medicine, particularly for the treatment of feline hyperthyroidism.

Production of I-131 radiopharmaceuticals is considered a high risk activity due to the volatile nature of iodine. Airborne I-131 is easily concentrated in the thyroid, so appropriate containment measures must be used. Due to this high risk nature, there are only a small number of radiopharmaceutical processing facilities in Canada. This case study looks at the decline in safety performance at one such facility, Isologic Innovative Radiopharmaceuticals Ltd. (IIR), and CNSC staff’s subsequent increase in regulatory oversight, thereby ensuring the protection of the public and the environment.

I.5.1.2 Background

This licensee has been expanding its operations in Canada for some years. In a short length of time, they increased the number of licensed locations under their processing licence from one location to seven and introduced the manufacturing of I-131 capsules to the services that they provide to their customers.

Over the course of a four-year period, from 2014 to 2018, CNSC staff observed a significant decline in safety performance, which began with the licensee reporting to the CNSC a series of events in 2014 involving contaminated packages that were delivered to multiple hospitals. In reviewing these events, CNSC staff concluded that, although these incidents were of minor safety significance due to the relatively low levels of contamination involved, the licensee did not have sufficient management oversight of their work practices. The RSO at the time committed to improve the management oversight practices within their organization.

In February 2017, CNSC staff conducted a Type I inspection of the licensee’s operations, which span locations across Canada; the results of this inspection demonstrated a further decline in performance. The concerns were related to the licensee’s management oversight of the radiation protection program, more specifically towards the I-131 manufacturing operations. The CNSC performed two follow-up inspections in May and October 2017. The licensee worked through the implementation of the corrective actions following these inspections.

In the fall of 2018, the licensee reported to the CNSC two events at one of their locations. The first occurred in November, when a nuclear energy worker (NEW) exceeded the equivalent dose limit to the skin of the hand while conducting therapeutic I-131 capsule production. A few days after the event, CNSC staff conducted an inspection at the licensee’s location. The inspection found several non-compliances with regulatory requirements, which included workers routinely not following procedures relevant to I-131 processing and personnel monitoring. In addition, CNSC staff concluded that the responsibilities for implementation and oversight of the Radiation Protection Program were not clearly understood and executed by licensee staff. The licensee reported the second event one month later, indicating that they had exceeded their quarterly and annual airborne release limits for I-131. CNSC staff presented the reported events and inspection findings to the Commission in CMD 18-M65 as an Event Initial Report on December 13, 2018. Six days later, a CNSC Designated Officer (DO) issued an order to the licensee to immediately cease all processing of I-131 until such time that actions are taken to train staff, conduct a root cause analysis on I-131 releases and establish a program to monitor workers’ adherence to procedures. In addition, the order required the licensee to immediately make provisions to ensure adequate supply of I-131 radiopharmaceutical products to Canadian patients throughout the time period of suspended processing. CNSC staff reported this DO order to the Commission and continued to provide updates to the Commission on several occasion in the 14 months that followed the issuance of the Order.

CNSC staff conducted two additional compliance inspections in 2019; based on the results of these inspections, CNSC staff determined that the licensee had met all the terms and conditions of the Order. As previously reported to the Commission, the Order was closed on January 7, 2020.

I.5.1.3 Regulatory Approach

The standard CNSC approach to regulatory oversight for licensees using nuclear substances and prescribed equipment focuses on regulating similar activities across multiple licensees. However, in the case of Isologic, which is the biggest provider of I-131 to the medical sector in Canada, CNSC staff recognized that due to the size of its operations, this licensee required a tailored regulatory oversight strategy.

In addressing the situation described through this case study, the CNSC took a much more active role in the review of the licensee’s procedures than is typically required with this type of licensee. The goal of CNSC staff was to assist the licensee to significantly improve their programs to prevent reoccurrence of similar events moving forward. The regulatory approach included regular progress meetings with the licensee, as well as a detailed review and oversight of the environmental protection program. CNSC staff used the expert knowledge of subject matter specialists including staff from radiation protection, environmental protection, licensing, and compliance, to review the licensee’s submissions and to provide recommendations to the licensee. The licensee implemented a number of corrective actions, which the CNSC closely monitored through a phased approval process with regulatory hold points.

In the end, this team-based approach determined that the licensee’s submissions addressed the causes of the non-compliances that resulted in the issuance of the DO Order, and that the restart of I-131 operations would continue to protect the environment, the health and safety of workers, and the public.

I.5.1.4 Conclusion

At this time, the licensee remains fully compliant in their I-131 operations and continues to work closely with the CNSC to implement continuing improvements to their management system within their organization. The CNSC is planning a further compliance inspection of this licensee before the end of 2020 to verify the implementation of additional commitments that have been made.

I.5.2 Positron Emission Tomography (PET) Isotope Cyclotron Facility

I.5.2.1 Introduction

Isotope production accelerators such as cyclotrons produce isotopes used in the synthesis of nuclear medicine radiopharamaceuticals, used primarily for nuclear medicine imaging. Isotope production licensees may produce isotopes for both clinical and research purposes.

The licensee examined in this case study, the Montreal Neurological Institute and Hospital, has been running a Positron Emission Tomography (PET) isotope cyclotron and associated processing laboratories for almost three decades. There are two laboratories in the facility: one to handle clinical production of Fluorodeoxyglucose (FDG), a radiopharmaceutical used in medical imaging, in a fully automated manner inside shielded cells (hotcells); the second is for making various isotopes and tracers used for research in a nearby hospital.

At this facility, processing isotopes in the research lab is not fully automated. While most of the processing is done automatically, certain steps involve handling of vials or syringes inside the hotcells. This is because the hotcells are not equipped with robotic arms or remote handling manipulators. This means workers use their hands in the process to handle vials or other samples through small arm doors in the hotcell front shielding.

I.5.2.2 Background

Action levels are intended to provide an early indication of a possible loss of control of part of a licensee’s radiation protection program. In January and February of 2017, the licensee reported to CNSC staff that the monthly extremity dose action levels of 450 mSv/y (extrapolated monthly) were exceeded for personnel processing radioisotopes. As this dose level was still below the regulatory equivalent dose limit of 500mSv/y, the licensee was still compliant with the Radiation Protection Regulations.

As part of routine regulatory oversight, CNSC staff performed a benchmark analysis of worker doses as a function of the annual production for 17 isotope production cyclotron licensees in Canada. The purpose of this analysis was to evaluate licensee performance in this sector by normalizing dose based on total production at the facility and the number of workers, taking into account the nature of the operation: research vs commercial production. The benchmarking analysis showed that this particular licensee’s workers received the highest extremity annual doses normalized to the facility annual production compared to similar licensees.

Prompted by these two indicators, CNSC staff decided to take additional actions, starting with enhanced monitoring of the licensee. An October 2017 inspection revealed that the licensee had made little progress toward reducing the collective extremity dose. CNSC staff requested that the licensee review all radiochemistry processes and begin monthly reporting outlining their progress toward the goal of reducing extremity doses.

The licensee complied with the CNSC staff request and subsequently committed to two improvements to help reduce extremity doses: namely, using special tools to increase the distance between the source and the fingers, and semi-automating certain setups to reduce handling. A follow up inspection in March 2019 indicated that the licensee was not following its own internal procedures.

In order to mitigate the risk of continued high extremity doses, a CNSC inspector issued an order to the licensee to prohibit any handling inside the hotcell of activity in excess of 11.1 GBq (300 mCi) until the licensee submitted adequate processes for minimizing worker doses. CNSC staff ultimately determined that the licensee had met all the terms and conditions of the Order, and the Order was subsequently closed on November 5, 2019.

I.5.2.3 Regulatory Approach

In addition to assessing licensee performance through standard compliance activities, such as conducting inspections and reviewing annual compliance reports, CNSC staff also monitor other indicators that help to flag possible areas of concern. In this case, a review of events reported by this licensee, combined with a benchmarking analysis of worker doses, led CNSC staff to increase its regulatory oversight of this licensee through the application of a number of compliance tools, applied in an escalated manner. As a result of these regulatory actions, the licensee improved its performance with respect to radiation safety.

I.5.2.4 Conclusion

The licensee has demonstrated a clear reduction of extremity doses: the maximum yearly extremity doses decreased from 348 mSv in 2018 to 196 mSv in 2019. CNSC staff continue to monitor licensee performance through a combination of desktop compliance verification and on-site inspections to ensure sustained good performance.

I.6 Stakeholder Engagement

Nuclear substance licensees are not required to have public information disclosure programs (unlike the Class IB Accelerator licensees covered in Part II of this report). Stakeholder engagement and outreach activities are performed by the CNSC to facilitate communication on licenced activities and regulatory expectations between the CNSC, nuclear substance licensees, the public, and Indigenous communities.

Stakeholder engagement and outreach are critical elements of the CNSC’s regulatory approach. Given the breadth of licensees regulated in the area of nuclear substances, a particular focus is on reaching and engaging with licensee communities, which leads to increased awareness and better understanding of the regulatory process and requirements. CNSC staff leverage a variety of fora to engage with licensees and promote the use of the tools that are developed to support their compliance with regulatory expectations. Inspections are a particularly valuable opportunity to engage directly with licensees.

CNSC outreach in 2019 included:

- Annual meetings with the radiography industry: The CNSC holds two separate annual meetings with the radiography industry. In 2019 the meetings were held in Ottawa, Ontario on May 8th and Nisku, Alberta on May 23rd. CNSC staff use these meetings to address recent and upcoming regulatory developments and discuss other areas of regulatory focus.

- Newsletter: One issue of the DNSR Newsletter was published in the summer of 2019.

- Working Groups:

- There were two meetings with the Industrial Radiography working group one in February and one in October 2019. The working group meets to discuss best practices and safety performance, and provides a forum in which stakeholders can stay informed of new developments from both technical and regulatory perspectives.

- There was also a meeting with the CRPA working group during the CRPA conference in May 2019. Topics for such meetings are varied, focusing on items of mutual interest, and are intended to foster open communications between CRPA and the CNSC. Topics have included: multi modality dose consideration in room approvals, designation of workers as NEWS without dose justification, discussion of upcoming regulatory documents and changes to the disposal table on licence.

- Industry meetings: CNSC staff met with the Canadian Council of Independent Laboratories in May 2019. CNSC Staff presented on trends in the portable gauge industry.

- Meetings with Indigenous groups: CNSC staff participated in Indigenous engagement outreach in Ontario and New Brunswick.

- Participation in CRPA meeting: CNSC staff delivered presentations at the Canadian Radiation Protection Association’s annual meeting in May 2019.

- Presentation to school students: CNSC staff participated in a STEM talk with students at a local Ottawa school, organized by Accelerator and Class II Facilities Division staff.

- Participation in COMP meeting: CNSC staff presented at the Canadian Organization of Medical Physicists annual scientific meeting in September 2019.

- Town Hall: CNSC staff held a virtual town hall meeting for Accelerator and Class II Facilities licensees. The Class II regulations were under review and changes to these regulations were discussed. There were 58 participants in this meeting.

I.7 Conclusion

In 2019, the majority of the inspected licensees were in compliance with the expectations of the SCAs in this report. Most of the enforcement actions taken in 2019 have been closed with the CNSC closely monitoring the three orders that are still open. Exposure to workers in 2019 continue to be very low and consistent with previous years. For the events reported in 2019, the licensees implemented appropriate responses to address the events, as determined by CNSC staff. CNSC staff continue to host outreach with various stakeholders to keep the public, Indigenous communities and licensees informed.

Through the case studies highlighted in this report the CNSC was able to improve compliance by helping licensees to focus on the right corrective actions to improve their performance.

Based on the CNSC’s comprehensive regulatory oversight of the industry, CNSC staff conclude that the use of nuclear substances and prescribed equipment in Canada is safe. Licensees corrected identified items of non-compliance to the satisfaction of CNSC staff; adequate provisions are in place to protect the health, safety and security of persons and the environment from the use of nuclear substances and prescribed equipment.

Part II: Class IB Accelerators in Canada: 2018-2019

The DNSR ROR: Part II presents the operating performance of the two Class IB accelerator facilities regulated by CNSC: the Tri University Meson Facility (TRIUMF) and the Canadian Light Source Inc. (CLSI).

TRIUMF operates one 520 megaelectronvolt (MeV) cyclotron accelerator facility, four smaller cyclotrons facilities, and three linear accelerator facilities. TRIUMF is located on the University of British Columbia campus in Vancouver, British Columbia. TRIUMF is a nuclear and particle physics research centre and is a major producer of radioisotopes used for medical diagnostic procedures. The 520-Mev cyclotron accelerator has been in operation since 1975.

CLSI operates a synchrotron facility, on the University of Saskatchewan campus in Saskatoon, Saskatchewan. The facility produces synchrotron radiation that is used as a light source for experiments in diverse fields. The facility has been in operation since 2005.

Public concern tends to be low regarding the safety performance of Class IB accelerator facilities. Since CNSC staff have been reporting the safety performance for the facilities it regulated (starting in 2013) the consultation process for the Class 1B accelerator ROR has never yielded comments from the public nor requests for participation at the Commission meetings. Therefore, the ROR on Class IB accelerators in Canada has been presented every second year since 2016.

II.1 Compliance Performance

The main hazards associated with Class IB accelerator facilities are radiological exposure and conventional industrial hazards. Nuclear substances are present as a result of deliberate irradiation of targets designed to produce desired isotopes, or as an unavoidable by-product generated in irradiated air or accelerator components. Consequently, TRIUMF`s environmental releases are very small and CLSI has no radioactive environmental releases resulting from the operation of the synchrotron.

CNSC staff conducted consistent and risk-informed regulatory oversight at the Class IB particle accelerator facilities. Table 20 of Appendix G presents the licensing and compliance efforts from CNSC staff for the Class IB accelerator facilities for 2018 and 2019.

During this two-year period, CNSC staff conducted six targeted onsite inspections, three at TRIUMF and three at CLSI. CNSC staff provided the findings from these inspections to the licensees in detailed inspection reports. Licensee corrective actions enacted in response to Notices of Non Compliance identified by CNSC staff are followed through to resolution.

These facilities are required, as part of their operating licences, to submit an annual compliance report (ACR) by June 30 each year. The review of these ACRs by CNSC subject matter experts complements the compliance inspections and provides verification of licensee performance on an annual basis.

In comparison with previous years, regulatory efforts increased slightly in 2018 and 2019. This was primarily due to increased assessment efforts in response to necessary changes for both facilities in order to implement CSA Standard N286-12, Management System Requirements for Nuclear Facilities, which came out in 2012. Compliance with this standard was required starting January 2018 for TRIUMF and CLSI. This is discussed further in the Management System section below.

CNSC staff use the SCA framework in evaluating each licensee's safety performance level. Each SCA is rated through compliance inspections, desktop reviews of events and incidents, and ACR review. These ratings are used as an indicator of performance and potential areas requiring attention from the licensee and CNSC staff. Compliance oversight plans are developed by CNSC staff, taking into consideration a number of factors, including these ratings. A facility performing below the satisfactory level in any of the SCAs will be subject to escalated enforcement by CNSC staff until the situation is remedied.

For calendar years 2018 and 2019, the performance in all 14 SCAs for TRIUMF was rated as satisfactory or better, with the exception of the Management System SCA (as discussed in section II.1.1.1). For the same time period, CLSI’s performance was rated satisfactory or better in all SCAs, with the exception of the Management System SCA in 2019 (as discussed in section II.1.1.2). Appendix H provides the SCA ratings for the past five years for TRIUMF (Table 14) and CLSI (Table 15).

II.1.1 Management System

The Management System SCA covers the framework which establishes the processes and programs required to ensure an organization achieves its safety objectives and continuously monitors its performance against these objectives and fostering a healthy safety culture.

Since January 2018, Class IB accelerator facilities are required to comply to CSA Standard N286-12, Management System Requirements for Nuclear Facilities, as stated in the licence condition handbook.

II.1.1.1 TRIUMF

In February 2016, CNSC staff carried out a management system inspection at TRIUMF. TRIUMF took corrective actions to address the findings from that inspection to CNSC satisfaction. Following the inspection, TRIUMF committed to comply with CSA Standard N286-12 by January 2018. However, it took longer than expected for TRIUMF to perform a gap analysis of their management system against N286-12 and therefore TRIUMF did not meet the deadline. TRIUMF decided to increase resources committed to this task and spent most of 2019 looking for a suitable quality assurance (QA) manager responsible for coordinating these compliance efforts. CNSC staff delayed the February 2019 management system inspection due to TRIUMF's lack of progress on performing the gap analysis and closing the gaps. In December 2019, TRIUMF hired a new QA manager. In March 2020, TRIUMF's new QA manager submitted a gap analysis report to CNSC staff. CNSC staff reviewed the gap analysis and focussed communications between the new QA manager and CNSC management specialists have now put TRIUMF on the right track to demonstrate that they will meet N286-12 requirements by the end of 2020. CNSC staff rescheduled the February 2019 management system inspection for the fall of 2020.

TRIUMF operates under an effective management system, which allows them to perform their licenced activities safely. However, CNSC staff rated TRIUMF below expectations for the Management System SCA for both 2018 and 2019 because TRIUMF failed to demonstrate compliance to CSA Standard N286-12. TRIUMF’s gap analysis of their management system against the standard may result in opportunities for improvements that will increase the defence in depth, resulting in increased safety. The delay does not pose an immediate risk to health and safety.

II.1.1.2 CLSI

CLSI performed a gap analysis of their management system against the N286-12 standard and updated their procedures accordingly in order to meet the January 2018 compliance date. Upon initial review of their revised management system program, CNSC staff determined that CLSI was compliant. Subsequently, CLSI underwent a management system inspection in July 2019, focused on N286-12 implementation. CNSC staff noted that CLSI had made some progress in their management system. However, it was also noted that CLSI was not complying with its own governance and the problem identification and resolution process was found to be non-compliant with N286-12 requirements.

CNSC staff concluded that CLSI is partially meeting the N286-12 requirements. Despite these non-compliances, CLSI has an effective management system and continues to safely operate the Class IB facility. Further compliance activities are planned in 2020 in order to follow up with the deficiencies flagged and ensure that CLSI is in full compliance with N286-12. As a result, CLSI has been rated as below expectations for the Management System SCA for 2019.

II.1.2 Radiation Protection

The Radiation Protection SCA covers the implementation of a radiation protection program in accordance with the Radiation Protection Regulations. The program must ensure that contamination levels and radiation doses received by individuals are monitored, controlled and maintained ALARA.

The rating for the Radiation Protection SCA for both Class IB accelerator facilities was satisfactory or better, which is unchanged from the previous three years. The ratings for the past five years are presented in Appendix H.

During 2018 and 2019, CNSC staff determined that all Class IB accelerator facilities implemented effective measures to keep radiation exposures and doses to persons ALARA. This has consistently resulted in doses to persons being well below CNSC regulatory dose limits.

All Class IB accelerator facilities continued to comply with the regulatory requirements to measure and record doses received by workers. Details are provided in section II.3 below.

Both TRIUMF and CLSI have put in place dose action levels that, if reached, may indicate a loss of control of part of their radiation protection program. In 2018 and 2019, there were no occurrences of dose exceeding action levels at either facility.

Both TRIUMF and CLSI have put in place comprehensive radiation dose area monitoring programs and surface contamination monitoring and mitigation programs. CNSC staff routinely verify the results and compare them to previous years’ results. No anomalies were noted in 2018 or 2019.

Doses to members of the public from the Class IB facilities has been consistently well below the CNSC regulatory dose limit for a member of the public of 1 mSv/year. For TRIUMF, the public dose trend for the last five year is presented in Table 23 of Appendix I. There are no airborne or liquid effluent releases of nuclear substances from CLSI. Therefore, the estimated dose to the public is at natural radiation background levels for this facility.

CNSC staff conclude that for 2018 and 2019, the Class IB accelerator facilities effectively maintained their radiation protection programs to ensure the health and safety of persons present in their facilities.

II.1.3 Conventional Health and Safety

The Conventional Health and Safety SCA covers the implementation of a program to manage workplace safety hazards and to protect personnel and equipment.

CNSC's risk-informed analysis of both Class IB particle accelerator facilities concluded that conventional health and safety is the only SCA for which both the probability of an accident is high and the impact is high. Therefore, the frequency of inspection of this SCA is the highest for all SCAs, with an interval of one to two years for TRIUMF and two to three years for CLSI. CNSC staff verified conventional health and safety at TRIUMF during the April 2018 inspection and again during the April 2019 inspection. CLSI's last conventional health and safety inspection was in 2017.

A key performance indicator for the conventional health and safety SCA is the lost-time injury rate. The lost-time injury rate is presented in Table 24 of Appendix J for the last five years, along with a description of all lost-time injuries for 2018 and 2019 in Table 18 of the same appendix.

The rating for the conventional health and safety SCA was satisfactory or better for both Class IB accelerator facilities in 2018-2019.

CNSC staff conclude that for 2018 and 2019, the Class IB accelerator facilities effectively maintained their conventional health and safety programs to ensure the health and safety of persons present in their facilities.

II.2 Enforcement

The CNSC uses a graduated approach to enforcement to encourage compliance. When non-compliance (or continued non-compliance) has been identified, CNSC staff assess the significance of the non-compliance and determine the appropriate enforcement action.

In 2018 and 2019, neither TRIUMF nor CLSI had enforcement actions.

II.3 Effective Doses to Workers

All Class IB accelerator facilities continued to comply with the regulatory requirements to measure and record doses received by workers. During 2018 and 2019, all Class IB accelerator facilities monitored and controlled the radiation exposures and doses received by all persons present at their licensed facilities, including workers, contractors and visitors. Figure 18 and 19 of Appendix K provides the effective doses to nuclear energy workers for Class IB accelerator facilities for this reporting period.

II.4 Reported Events

For 2018-2019, TRIUMF had 11 eventsFootnote 2 and CLSI had six events. Appendix L describes these events in detail. For each event reported, the licensees performed an internal investigation and implemented corrective actions to prevent reoccurrences. Both facilities reported these events to CNSC as required by the regulations or the licence conditions. In each case, CNSC staff reviewed the report and corrective actions and found them to be satisfactory.

II.5 Public Information and Disclosure Program

Class IB accelerator facilities have a responsibility to inform the public about their nuclear facilities and activities. CNSC staff recognize that Class IB accelerators are low-risk facilities and that a full-scale public information program, as undertaken by larger nuclear facilities, is not warranted. However, the CNSC requires these licensees to provide open and transparent information to the public. The objective is to ensure that timely information about the health, safety and security of persons and the environment and other issues associated with the nuclear facility are effectively communicated.

The public information and disclosure program was established in December 2018 for TRIUMF and in September 2018 for CLSI.

CNSC staff verified through annual compliance reporting that public information and disclosure programs were being implemented satisfactorily during 2018-2019. The CNSC has provided feedback on their communications programs to CLSI and TRIUMF, including areas for improvement to ensure that the programs remain effective at communicating useful information about the health, safety and security of persons and the environment and other matters of public interest associated with these facilities.

II.6 Conclusion

Through regulatory oversight activities, CNSC staff confirmed that Class IB Particle Accelerator facilities in Canada continued to operate safely in 2018 and 2019. The regulatory oversight activities included inspections, review of reports submitted by licensees, event and incident review with follow-up, general communication and exchanges of information with the licensees.

For the three SCAs presented in detail in this report, CNSC staff concluded that both the radiation program and the conventional health and safety program were satisfactory. However, the implementation of CSA Standard N286-12 into the management system of both Class IB accelerator facilities has been a challenge during the reporting period. As a result, CNSC staff has increased their regulatory efforts to bring both facilities closer to full compliance with the standard.

CNSC staff conclude that for the reporting period, both TRIUMF and CLS made adequate provision for the health and safety of workers, the protection of the public and the environment, as well as Canada's international obligations.

Appendices A to F cover data linked to Part I of this report; appendices G to L link to Part II; and appendices M to P provide generic information applicable to both.

Appendix A: Regulatory Program for the Use of Nuclear Substances

This section presents additional regulatory data to complement the information provided in the main part of the document.

A.1 CNSC regulatory effort

| Type of decision | Number of decisions |

|---|---|

| Licensing (issuance of new licenses, licence renewals, licence amendments, licence revocations and licence transfers) | 1,780 |

| Certification of prescribed equipment (radiation devices, Class II prescribed equipment and transport packages) | 71 |

| Certification of exposure device operators (EDOs) (issuance of new certification and renewal of certification) | 498 |

| Certification of Class II RSOs | 9 |

| Total | 2,358 |

| Activity | Person-days |

|---|---|

| Licensing | 4,648 |

| Certification | 1,237 |

| Compliance verification | 6,061 |

A.2 Licensing

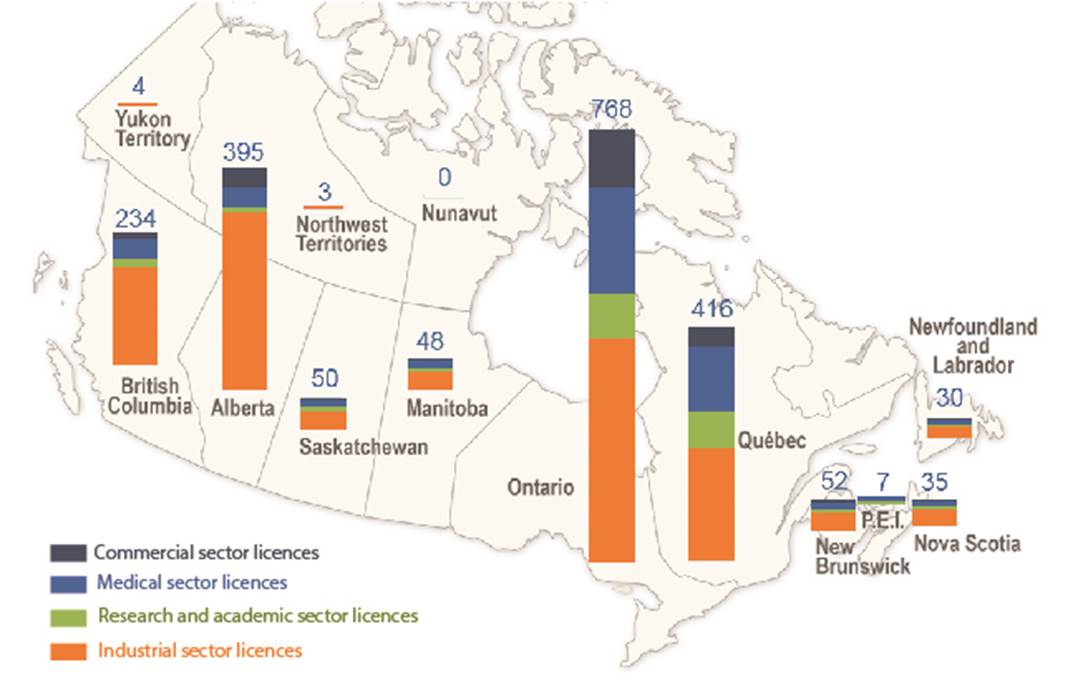

In 2019, there were 2,090 licenses held for the use of nuclear substances and prescribed equipment (Table 3). The licensees are located throughout Canada, as indicated in figure 1.

| Sector | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|

| Medical | 494 | 470 | 457 | 436 | 438 |

| Industrial | 1,349 | 1,308 | 1,287 | 1,259 | 1,228 |

| Academic and research | 207 | 208 | 195 | 192 | 187 |

| Commercial | 251 | 254 | 252 | 248 | 237 |

| Total | 2,301 | 2,240 | 2,191 | 2,135 | 2,090 |

Figure 1: Text version

| Industrial | Academic | Medical | Commercial | |

|---|---|---|---|---|

| Alberta (AB) | 315 | 10 | 37 | 33 |

| British Columbia (BC) | 167 | 18 | 39 | 10 |

| Manitoba (MB) | 23 | 8 | 13 | 4 |

| New Brunswick (NB) | 30 | 5 | 14 | 3 |

| Newfoundland and Labrador (NL) | 21 | 1 | 6 | 2 |

| Northwest Territories (NT) | 3 | 0 | 0 | 0 |

| Nova Scotia (NS) | 23 | 3 | 5 | 4 |

| Nunavut (NU) | 0 | 0 | 0 | 0 |

| Ontario (ON) | 396 | 78 | 190 | 104 |

| Prince Edward Island (PE) | 2 | 1 | 4 | 0 |

| Quebec (QC) | 200 | 58 | 119 | 39 |

| Saskatchewan (SK) | 32 | 5 | 11 | 2 |

| Yukon (YT) | 4 | 0 | 0 | 0 |

A.3 Certification of prescribed equipment and transport packages

As seen in Table 1, designated officers made 71 decisions related to the certification of prescribed equipment (40) or transport packages (31).

A.4 Certification of exposure device operators

Licensees are required under the Nuclear Substances and Radiation Devices Regulations to permit only CNSC-certified personnel and supervised trainees to use exposure devices containing nuclear substances. In 2019, the CNSC certified 113 new exposure device operators (EDOs) and renewed the certifications of 385 others.

A.5 Certification of Class II radiation safety officers

All licensees that operate Class II nuclear facilities or that service Class II prescribed equipment must have a certified radiation safety officer (RSO) and a qualified temporary replacement. The RSO ensures that licensed activities are conducted safely and all regulatory expectations are met.

In 2019, the CNSC certified 9 Class II RSOs. No Class II RSOs were decertified in 2019.

Appendix B: Compliance Performance

B.1 Management System

For the management system SCA, 97% of the licensees inspected ensured that adequate processes and programs were in place to achieve their safety objectives (figures 2 and 3). Three licensees received unacceptable ratings in this SCA. There was one unacceptable results from the medical sector, one from the industrial sector and one from the commercial sector. For any unacceptable ratings, CNSC staff ensure that licensees took appropriate corrective actions. Licensees immediately addressed any items of non-compliance that had immediate risks to health, safety or security. The industrial licensee was issued an order(refer to order #1058 in Appendix C for further details). CNSC staff are monitoring the medical licensee’s progress for correcting the findings from the inspection. The commercial licensee has addressed all items of non-compliance and CNSC staff will further evaluate responses during the inspection scheduled in 2020.

Figure 2: Text version

| 2015 | 2016 | 2017 | 2018 | 2019 | |

|---|---|---|---|---|---|

| Meets expectation | 1241 | 1265 | 840 | 843 | 739 |

| Below requirements | 51 | 27 | 23 | 29 | 22 |

| Unacceptable | 0 | 2 | 1 | 0 | 3 |

| Total | 1292 | 1294 | 864 | 872 | 764 |

Figure 3: Text version

| 2015 | 2016 | 2017 | 2018 | 2019 | |

|---|---|---|---|---|---|

| Medical | 227 | 207 | 106 | 110 | 155 |

| Industrial | 837 | 901 | 605 | 608 | 475 |

| Academic and research | 67 | 73 | 71 | 85 | 73 |

| Commercial | 110 | 84 | 58 | 40 | 36 |

| All sectors combined | 1241 | 1265 | 840 | 843 | 739 |

B.2 Operating Performance

In the operating performance SCA, 86% of the licensees inspected made adequate provisions for health, safety, security, and the protection of the environment. In 2019, the operating performance SCA slightly improved from the 84% fully compliant, to 86%(figures 4 and 5).

Two licensees received an unacceptable rating in operating performance. One was from the industrial sector and one was from the academic and research sector. The industrial licensee was issued an order (refer to order #1112 in Appendix C for further details). The academic and research licensee has since implemented corrective measures that were reviewed by CNSC staff and were determined to be satisfactory.

Figure 4: Text version

| 2015 | 2016 | 2017 | 2018 | 2019 | |

|---|---|---|---|---|---|

| Meets expectation | 1189 | 1151 | 747 | 747 | 673 |

| Below requirements | 120 | 161 | 128 | 144 | 110 |

| Unacceptable | 2 | 5 | 8 | 4 | 2 |

| Total | 1311 | 1317 | 883 | 895 | 785 |

Figure 5: Text version

| 2015 | 2016 | 2017 | 2018 | 2019 | |

|---|---|---|---|---|---|

| Medical | 229 | 201 | 100 | 96 | 155 |

| Industrial | 785 | 792 | 511 | 528 | 409 |

| Academic and research | 60 | 74 | 73 | 79 | 70 |

| Commercial | 115 | 84 | 63 | 44 | 38 |

| All sectors combined | 1189 | 1151 | 747 | 747 | 672 |

B.3 Radiation Protection

In the radiation protection SCA, 80% of the licensees inspected had adequate measures and programs in place to ensure that exposure to workers and the public to ionizing radiation was monitored, and controlled, and remained ALARA (as low as reasonably achievable). Overall, this SCA has been trending downwards for the past few years from 89% meeting expectations in 2015 to 80% in 2019 (figures 6 and 7).

One industrial licensee received an unacceptable rating in radiation protection. The licensee was issued an order (refer to order #1207 in Appendix C for further details).

Figure 6: Text version

| 2015 | 2016 | 2017 | 2018 | 2019 | |

|---|---|---|---|---|---|

| Meets expectation | 1159 | 1112 | 744 | 748 | 629 |

| Below requirements | 146 | 199 | 129 | 137 | 160 |

| Unacceptable | 0 | 4 | 3 | 6 | 1 |

| Total | 1305 | 1315 | 873 | 891 | 790 |

Figure 7: Text version

| 2015 | 2016 | 2017 | 2018 | 2019 | |

|---|---|---|---|---|---|

| Medical | 212 | 185 | 94 | 95 | 132 |

| Industrial | 768 | 773 | 518 | 539 | 387 |

| Academic and research | 65 | 71 | 69 | 68 | 71 |

| Commercial | 114 | 83 | 63 | 46 | 39 |

| All sectors combined | 1159 | 1112 | 744 | 748 | 629 |

B.4 Security

In 2019, licensees’ performance in the security SCA improved from previous years; 95% of inspected licensees (719 of 760) received fully satisfactory or satisfactory ratings (figures 8 and 9).

None of the licensees received an unacceptable rating for the Security SCA.

Figure 8: Text version

| 2015 | 2016 | 2017 | 2018 | 2019 | |

|---|---|---|---|---|---|

| Meets expectation | 1157 | 1159 | 764 | 764 | 719 |

| Below requirements | 59 | 78 | 77 | 68 | 41 |

| Unacceptable | 2 | 1 | 9 | 1 | 0 |

| Total | 1218 | 1238 | 850 | 850 | 760 |

Figure 9: Text version

| 2015 | 2016 | 2017 | 2018 | 2019 | |

|---|---|---|---|---|---|

| Medical | 219 | 190 | 96 | 96 | 158 |

| Industrial | 780 | 830 | 552 | 587 | 457 |

| Academic and research | 64 | 70 | 66 | 57 | 72 |

| Commercial | 94 | 69 | 50 | 46 | 32 |

| All sectors combined | 1157 | 1159 | 764 | 786 | 719 |

B.5 Inspection rating, by sector

B.5.1 Medical sector

Tables 4 to 7 in this appendix shows the inspection performance of licensees in the medical sector. The performance of the subsectors is shown for the years 2015 – 2019 as a percentage of the inspections that received fully satisfactory or satisfactory grades for the SCA and the total number of inspections where performance in that SCA was assessed. The number of inspections for the medical sector is the aggregate for the entire sector, including subsectors not highlighted in Part I.

A breakdown by subsector is not provided for the security SCA given the potentially sensitive information associated with that SCA.

| SCA | Subsector or sector | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|---|

| Management system | Nuclear medicine | 93% (203) | 96% (174) | 98% (91) | 96% (103) | 95% (103) |

| Radiation therapy | 93% (14) | 67% (10) | 82% (11) | 50% (6) | 100% (4) | |

| Veterinary nuclear medicine | 100% (6) | 100% (9) | 100% (4) | 100% (4) | 75% (4) | |

| Medical sector | 94% (242) | 96% (216) | 97% (110) | 94% (117) | 95% (163) |

| SCA | Subsector or sector | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|---|

| Operating Performance | Nuclear medicine | 93% (205) | 86% (184) | 86% (90) | 77% (104) | 87% (155) |

| Radiation therapy | 93% (14) | 92% (24) | 89% (18) | 67% (12) | 100% (21) | |

| Veterinary nuclear medicine | 100% (6) | 100% (9) | 100% (4) | 100% (4) | 100% (3) | |

| Medical sector | 93% (246) | 88% (228) | 87% (116) | 77% (124) | 88% (176) |

| SCA | Subsector or sector | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|---|

| Radiation Protection | Nuclear medicine | 85% (205) | 77% (186) | 75% (89) | 74% (104) | 70% (155) |

| Radiation therapy | 100% (15) | 100% (24) | 100% (19) | 100% (12) | 100% (13) | |

| Veterinary nuclear medicine | 83% (6) | 67% (9) | 100% (4) | 50% (4) | 100% (3) | |

| Medical sector | 86% (246) | 80% (231) | 81% (116) | 77% (124) | 74% (178) |

| SCA | Subsector or sector | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|---|

| Security | Medical Sector | 98% (223) | 86% (222) | 81% (118) | 91% (119) | 94% (168) |

B.5.2 Industrial sector

Tables 8 to 11 in this appendix shows the inspection performance of licensees in the industrial sector. The performance of the subsectors is shown for the years 2015 – 2019 as a percentage of the inspections that received fully satisfactory or satisfactory grades for the SCA and the total number of inspections where performance in that SCA was assessed. The number of inspections for the industrial sector is the aggregate for the entire sector, including subsectors not highlighted in Part I.

A breakdown by subsector is not provided for the security SCA given the potentially sensitive information associated with that SCA.

| SCA | Subsector or sector | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|---|

| Management system | Portable gauge | 99% (338) | 98% (443) | 99% (303) | 98% (321) | 100% (215) |

| Fixed gauge | 96% (170) | 100% (205) | 94% (130) | 94% (112) | 94% (124) | |

| Industrial radiography | 96% (163) | 97% (201) | 96% (136) | 96% (138) | 98% (114) | |

| Oil well logging | 98% (50) | 100% (48) | 100% (42) | 98% (43) | 100% (24) | |

| Industrial sector | 97% (860) | 98% (916) | 98% (620) | 97% (608) | 98% (487) |

| SCA | Subsector or sector | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|---|

| Operating Performance | Portable gauge | 92% (389) | 87% (439) | 82% (305) | 86% (326) | 82% (216) |

| Fixed gauge | 90% (170) | 77% (205) | 70% (136) | 68% (111) | 73% (124) | |

| Industrial radiography | 92% (190) | 94% (199) | 89% (116) | 88% (138) | 93% (114) | |

| Oil well logging | 77% (49) | 90% (48) | 93% (42) | 86% (44) | 100% (24) | |

| Industrial sector | 91% (865) | 86% (917) | 82% (625) | 83% (633) | 83.9% (484) |

| SCA | Subsector or sector | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|---|

| Radiation Protection | Portable gauge | 91% (389) | 84% (442) | 82% (306) | 84% (326) | 74% (216) |

| Fixed gauge | 80% (170) | 78% (205) | 80% (132) | 77% (111) | 73% (124) | |

| Industrial radiography | 92% (189) | 92% (198) | 90% (130) | 91% (138) | 92% (114) | |

| Oil well logging | 90% (48) | 79% (48) | 86% (42) | 91% (44) | 92% (24) | |

| Industrial sector | 89% (862) | 84% (916) | 84% (620) | 85% (633) | 79% (483) |

| SCA | Subsector or sector | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|---|

| Security | Industrial Sector | 94% (828) | 95% (873) | 91% (610) | 94% (624) | 94% (484) |

B.5.3 Academic and research sector

Tables 12 to 15 in this appendix shows the inspection performance of licensees in the Academic and Research sector. The performance of the subsectors is shown for the years 2015 – 2019 as a percentage of the inspections that received fully satisfactory or satisfactory grades for the SCA and the total number of inspections for which performance in that SCA was assessed. The number of inspections for the Academic and Research sector is the aggregate for the entire sector, including subsectors not highlighted in Part I.

A breakdown by subsector is not provided for the security SCA given the potentially sensitive information associated with that SCA.

| SCA | Subsector or sector | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|---|

| Management system | Laboratory studies and consolidated use | 95% (61) | 97% (71) | 97% (73) | 99% (84) | 99% (74) |

| Academic and research sector | 94% (71) | 97% (75) | 97% (73) | 99% (86) | 99% (74) |

| SCA | Subsector or sector | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|---|

| Operating Performance | Laboratory studies and consolidated use | 75% (63) | 92% (75) | 97% (74) | 88% (86) | 95% (74) |

| Academic and research sector | 78% (77) | 91% (81) | 97% (75) | 88% (90) | 95% (74) |

| SCA | Subsector or sector | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|---|

| Radiation Protection | Laboratory studies and consolidated use | 75% (63) | 92% (75) | 97% (74) | 88% (86) | 93% (74) |

| Academic and research sector | 78% (77) | 91% (81) | 97% (75) | 88% (90) | 93% (74) |

| SCA | Subsector or sector | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|---|

| Security | Academic and research sector | 91% (70) | 96% (73) | 96% (69) | 79% (72) | 99% (73) |

B.5.4 Commercial sector

Table 16 shows the inspection performance of licensees in the commercial sector. The performance of the sectors is shown for the years 2015 – 2019 as a percentage of the inspections that received fully satisfactory or satisfactory grades for the SCA and the total number of inspections for which performance in that SCA was assessed. The number of inspections for the commercial sector is the aggregate for the entire sector.

Due to the small number of inspections in each subsector, a breakdown by subsector is not provided. Identifying trends would be difficult in subsectors due to the low number of licensees in many subsectors.

| SCA | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|

| Management System | 94% (117) | 97% (87) | 93% (62) | 97% (41) | 97% (40) |

| Operating Performance | 94% (123) | 92% (91) | 94% (67) | 92% (48) | 89% (36) |

| Radiation Protection | 92% (125) | 92% (90) | 95% (63) | 100% (46) | 83% (48) |

| Security | 97% (97) | 99% (70) | 94% (53) | 93% (41) | 91% (35) |

Performance in the environmental protection SCA and conventional health and safety SCA are reported on only for the waste nuclear substance subsector. No waste nuclear substance licensees received below expectations or unacceptable ratings in the environmental protection SCA. The waste nuclear substance licensees continue to manage and monitor environmental releases as a result of licensed activities. These releases are kept well below regulatory limits. There were no unplanned releases to the environment as a result of licensed activities in 2019.

No waste nuclear substance licensees received below expectations or unacceptable ratings in the conventional health and safety SCA. The licensees continue to implement a health and safety program in accordance with the applicable occupational health and safety legislation to protect the health and safety of their workers.

Appendix C: Enforcement Actions Issued in 2019

In 2019, CNSC staff issued 13 orders and zero AMPs to licensees covered by Part I (Figure 10). Three of the orders are still open. The majority of the enforcement actions were issued to licensees in the industrial sector, consistent with previous years. A list of orders issued are included in table 17.

For one licensee, other enforcement actions were required by the CNSC in addition to an order. The CNSC required a warrant to seize devices from the licensee and a court order to dispose of the seized devices through a licensed disposal provider. This was presented to the commission in CMD 19-H107.

Figure 10: Text version

| 2015 | 2016 | 2017 | 2018 | 2019 | |

|---|---|---|---|---|---|

| Medical | 2 | 1 | 0 | 1 | 0 |

| Industrial | 14 | 18 | 23 | 14 | 9 |

| Academic and research | 1 | 0 | 0 | 0 | 0 |

| Commercial | 6 | 3 | 1 | 1 | 4 |

| All sectors combined | 23 | 22 | 24 | 16 | 13 |

| Issue date (2019) | Order # | Location | Licensee | Sector, subsector | Licensee response | Closure date (2019) |

|---|---|---|---|---|---|---|

| March 7, 2019 | 1207 | Brampton, Ontario | Orbit Engineering Limited | Industrial Sector, Portable Gauge | Ceased all use of its portable gauges and made immediate provisions to secure and store them until improvements were made to the management oversight of the radiation protection program and all items of non-compliance were corrected to the satisfaction of the CNSC. | March 15 |

| March 20, 2019 | 0838 | St. Catharines, Ontario | Trenergy Inc | Industrial Sector, Industrial Radiography | Immediately placed all radioactive materials in secure storage and ceased all activities involving radioactive materials until improvements were made to the management control of the radiation protection program and work practices to the satisfaction of the CNSC. Corrected all items of non-compliance to the satisfaction of the CNSC. | April 26 |

| March 22, 2019 | N/A | Port Alice, British Columbia | Neucel Specialty Cellulose Ltd. | Industrial Sector, Fixed Gauge | The licensee failed to comply with the order within the specified time frame. The RCMP obtained and then executed a warrant on May 30, 2019 to seize the devices at the request of the CNSC. At this time, CNSC staff accompanied a licensed third party who removed all devices at the location and transported them to a licensed site for secure storage. The Federal Court authorised the CNSC to dispose of the seized gauges on January 29th 2020. On June 25, 2019, the Commission approved the revocation of Neucel’s licence. | The CNSC seized the gauges on May 30, 2019. The Commission revoked the licence on June 25, 2019. |

| April 24, 2019 | 0759 | Calgary, Alberta | Canadian Construction Materials Engineering & Testing Inc | Industrial Sector, Portable Gauge | Ceased all use and transportation of its radiation devices and immediately placed them into secure storage until improvements were made to the management control of the radiation protection program and work practices and all items of non-compliance were corrected to the satisfaction of the CNSC. | May 10 |

| April 25, 2019 | 1117 | Edmonton, Alberta | Alpha Adroit Engineering Ltd | Industrial Sector, Portable Gauge | Ceased all use and transportation of its radiation devices and immediately placed them into secure storage until improvements were made to the radiation protection program and all items of non-compliance were corrected to the satisfaction of the CNSC. | May 7 |

| May 28, 2019 | 0599 | Red Deer, Alberta | Union Street Geotechnical Ltd. | Industrial Sector, Portable Gauge | Prohibited the worker from operating portable gauges until the worker received training in radiation safety and in the safe use of portable gauges to the satisfaction of the CNSC. Corrected all items of non-compliance to the satisfaction of the CNSC. | May 30 |

| June 18, 2019 | 1112 | Long Harbour, Newfoundland | Vale Newfoundland & Labrador Limited | Industrial Sector, Fixed Gauge | Immediately ceased worker entry into vessels fitted with radiation devices until appropriate training was developed for workers entering vessels fitted with radiation devices, a system was developed to ensure training was provided to workers entering such vessels and improved documentation related to vessel entry requirements to the satisfaction of the CNSC. Corrected all non-compliances to the satisfaction of the CNSC. | October 3 |

| July 10, 2019 | 1224 | Wonowon, British Columbia | Allnorth Consultants Limited | Industrial Sector, Portable Gauge | Removed the worker from all activities involving radiation devices until the worker was adequately retrained in all aspects of safe radiation device handling and operations and until all items of non-compliance were corrected to the satisfaction of the CNSC. | September 12 |

| September 12, 2019 | 0561 | Montreal, Québec | Montreal Neurological Institute and Hospital | Commercial, Isotope Production Accelerator Facility | Restricted hotcell activity to ensure that doses to workers are ALARA. The licensee improved the safety of the handling procedures. After implementing the changes, there was a reduction in the extremity doses to employees. | November 5 |

| September 23, 2019 | 1058 | Delta, British Columbia | High Precision Monitoring & Analysis Ltd. | Industrial Sector, X-ray Fluorescence Device | A warrant was planned for early 2020 and had to be put on hold due to COVID-19 concerns with the execution of the warrant. | Order is still open |

| December 6, 2019 | 1209 | Location information will be provided when the order is closed | Licensee information will be provided when the order is closed | Commercial | This order was issued due to security related concerns and remains open. | Order is still open |

| December 13, 2019 | 6062675 | Brantford, Ontario | Mississauga Metal and Alloys Inc. | WNSL | The licensee working on revising the radiation protection program to address the order. Financial impacts of COVID-19 have resulted in reallocation of resources and delayed completion of revisions to the radiation protection program. | Order is still open |

| Dec. 19, 2018 | n/a | Burlington, ON | Isologic Innovative Radiopharmaceuticals Ltd. | Commercial sector, Processing of nuclear substances | The Licensee has demonstrated a strong commitment in improving the safety of their I-131 production activities through:

| January 7, 2020 |

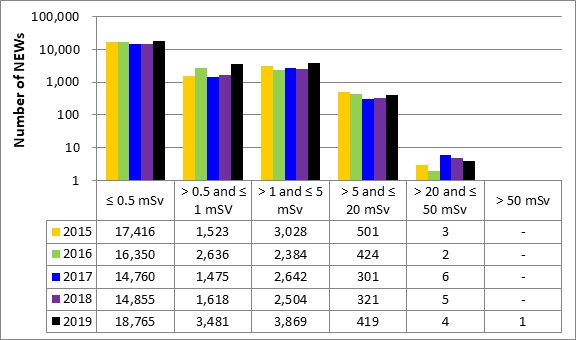

Appendix D: Doses to Workers

A total of 63,015 workers in the four sectors covered in Part 1 were monitored for occupational doses in 2019, 26,539 of whom were classified as Nuclear Energy Workers (NEWs). The differences in doses to workers among sectors reflect the nature of the various activities within those sectors. Figure 11 shows the doses received by the 26,539 NEWs monitored in 2019, while figure 12 shows the doses of NEWs from 2015 to 2019.

Figure 11: Text version

| ≤ 0.5 mSv | > 0.5 and ≤ 1 mSv | > 1 and ≤ 5 mSv | > 5 and ≤ 20 mSv | > 20 and ≤ 50 mSv | > 50 mSv | |

|---|---|---|---|---|---|---|

| Medical | 6,337 | 610 | 1,441 | 85 | 1 | 1 |

| Industrial | 6,796 | 2,581 | 2,073 | 296 | 3 | - |

| Academic and research | 3,049 | 88 | 53 | 3 | - | - |

| Commercial | 2,219 | 202 | 302 | 35 | - | - |

Figure 12: Text version

| ≤ 0.5 mSv | > 0.5 and ≤ 1 mSV | > 1 and ≤ 5 mSv | > 5 and ≤ 20 mSv | > 20 and ≤ 50 mSv | > 50 mSv | |

|---|---|---|---|---|---|---|

| 2015 | 17,416 | 1,523 | 3,028 | 501 | 3 | - |

| 2016 | 16,350 | 2,636 | 2,384 | 424 | 2 | - |

| 2017 | 14,760 | 1,475 | 2,642 | 301 | 6 | - |

| 2018 | 14,855 | 1,618 | 2,504 | 321 | 5 | - |

| 2019 | 18,765 | 3,481 | 3,869 | 419 | 4 | 1 |

In 2019, one non-NEW worker in the medical sector received a dose of 1.85 mSv. This is above the regulatory limit of 1 mSv/year for a worker who is not a NEW. The licensee could not come up with a reasonable explanation for the exceedance. The manufacturer did not find any anomalies with the dosimeter. CNSC staff issued a return to work letter with increased monitoring with a direct reading dosimeter. All doses recorded during the 6 month period after the event were normal.

In 2019, a NEW exceeded the whole body dose limit of 50 mSv. The employee was from the medical sector and the dose to the employee was 57 mSv. The licensee's investigation did not reveal any root cause for the dose and the dose is likely non-personal; however a non-personal dose assumption cannot be supported. The worker was initially removed from tasks that could add to the dose. On December 18, 2019, the licensee made a request to the CNSC for an authorization to return the affected worker to work. CNSC staff evaluated this request and the authorization was granted. This event was reported at the Commission hearing in June 2020.

D.1 Medical sector

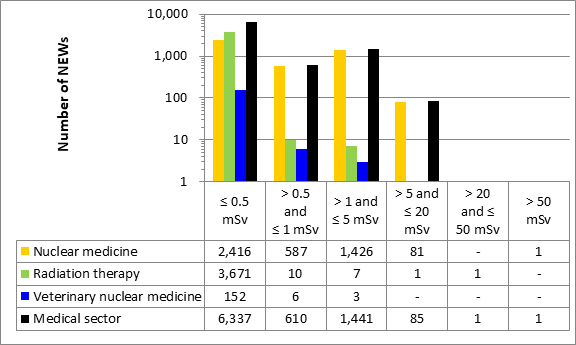

This appendix shows the doses received by NEWs in the medical sector, as reported to the CNSC in 2019 (Figure 13). Note that the total number of NEWs shown in the medical sector row is the aggregate for the entire sector, including subsectors not highlighted in Part I. Results are similar to past years.

Figure 13: Text version

| ≤ 0.5 mSv | > 0.5 and ≤ 1 mSv | > 1 and ≤ 5 mSv | > 5 and ≤ 20 mSv | > 20 and ≤ 50 mSv | > 50 mSv | |

|---|---|---|---|---|---|---|

| Nuclear medicine | 2,416 | 587 | 1,426 | 81 | - | 1 |

| Radiation therapy | 3,671 | 10 | 7 | 1 | 1 | - |

| Veterinary nuclear medicine | 152 | 6 | 3 | - | - | - |

| Medical sector | 6,337 | 610 | 1,441 | 85 | 1 | 1 |

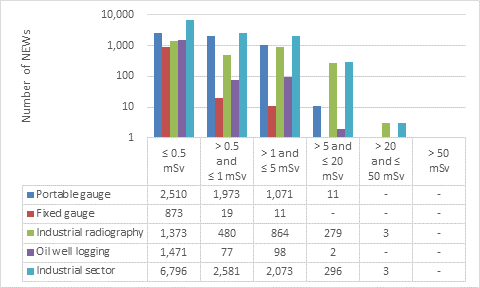

D.2 Industrial sector

This appendix shows the doses received by NEWs in the industrial sector, as reported to the CNSC in 2019 (Figure 14). Note that the total number of NEWs shown in the industrial sector row is the aggregate for the entire sector, including subsectors not highlighted in Part I. Results are similar to past years.

Figure 14: Text version

| ≤ 0.5 mSv | > 0.5 and ≤ 1 mSv | > 1 and ≤ 5 mSv | > 5 and ≤ 20 mSv | > 20 and ≤ 50 mSv | > 50 mSv | |

|---|---|---|---|---|---|---|

| Portable gauge | 2,510 | 1,973 | 1,071 | 11 | - | - |

| Fixed gauge | 873 | 19 | 11 | - | - | - |

| Industrial radiography | 1,373 | 480 | 864 | 279 | 3 | - |

| Oil well logging | 1,471 | 77 | 98 | 2 | - | - |

| Industrial sector | 6,796 | 2,581 | 2,073 | 296 | 3 | - |

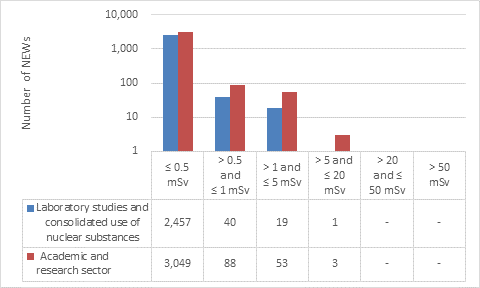

D.3 Academic and research sector

This appendix shows the doses received by NEWs in the academic and research sector, as reported to the CNSC in 2019 (Figure 15). Note that the total number of NEWs shown in the academic and research sector row is the aggregate for the entire sector, including subsectors not highlighted in Part I. Results are similar to past years.

Doses received by NEWs working at the CNSC laboratory remained very low, with all workers receiving doses below 0.5 mSv.

Figure 15: Text version

| ≤ 0.5 mSv | > 0.5 and ≤ 1 mSv | > 1 and ≤ 5 mSv | > 5 and ≤ 20 mSv | > 20 and ≤ 50 mSv | > 50 mSv | |

|---|---|---|---|---|---|---|

| Laboratory studies and consolidated use of nuclear substances | 2,457 | 40 | 19 | 1 | - | - |

| Academic and research sector | 3,049 | 88 | 53 | 3 | - | - |

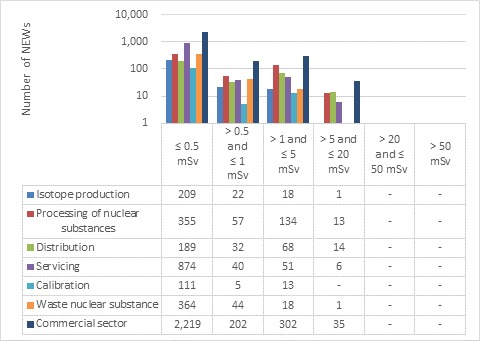

D.4 Commercial sector

This appendix shows the doses received by NEWs in the commercial sector, as reported to the CNSC in 2019 (Figure 16). Note that the total number of NEWs shown in the commercial sector row is the aggregate for the entire sector, including subsectors not highlighted in Part I. Results are similar to past years.

Figure 16: Text version

| ≤ 0.5 mSv | > 0.5 and ≤ 1 mSv | > 1 and ≤ 5 mSv | > 5 and ≤ 20 mSv | > 20 and ≤ 50 mSv | > 50 mSv | |

|---|---|---|---|---|---|---|

| Isotope production | 209 | 22 | 18 | 1 | - | - |

| Processing of nuclear substances | 355 | 57 | 134 | 13 | - | - |

| Distribution | 189 | 32 | 68 | 14 | - | - |

| Servicing | 874 | 40 | 51 | 6 | - | - |

| Calibration | 111 | 5 | 13 | - | - | - |

| Waste nuclear substance | 364 | 44 | 18 | 1 | - | - |

| Commercial sector | 2,219 | 202 | 302 | 35 | - | - |

Appendix E: Reported Events

Licensees are required to have programs in place for the management of unplanned events and accidents. The events that warrant mandatory reporting and the content of the reports are set out in the NSCA, its regulations and the licence conditions. CNSC staff review, assess and track all events reported by licensees.

Since 2014, reported events have been ranked using the International Nuclear and Radiological Event Scale (INES), a tool for communicating the safety significance of nuclear and radiological events to the public. Note that the scale is not a tool for comparing safety performances among facilities or organizations, but rather for effectively communicating the safety significance of events.

In 2019, 183 events related to nuclear substances and prescribed equipment were reported to the CNSC (Figure 17). Of these events, 181 ranked as INES level 0 (no safety significance), one was ranked as INES level 1 (anomaly), and one was ranked as INES level 2 (incident). A description of each event can be found in Table 18.